Overview

With millions of customers looking to buy high quality products at the same time, mass production is the only way to manufacture such astronomical quantities.

In this endeavour to produce en masse, manufacturers put increased emphasis on keeping manufacturing costs low by producing uniform products using repetitive and standardized processes.

As products become more complicated to produce, mass production becomes more complex. In this blog, we would try to understand the intricacies of manufacturing, while focusing on the food industry.

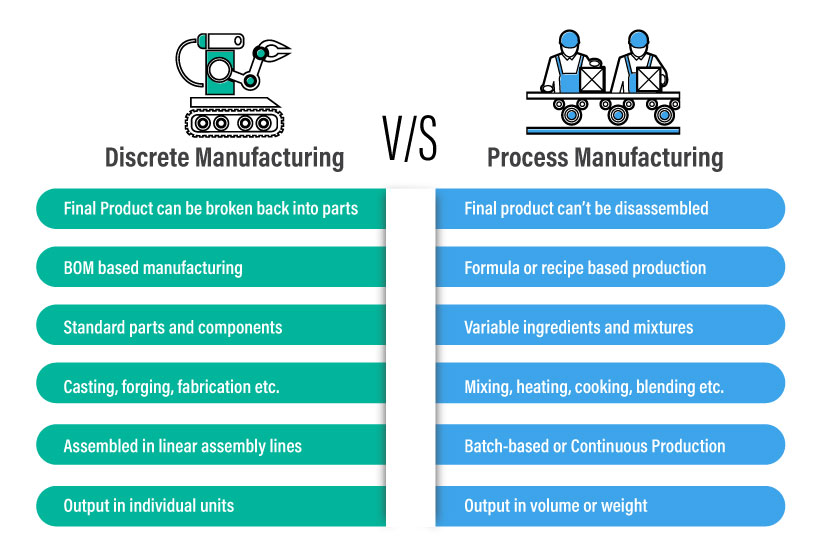

The methods of production can be classified into two categories – discrete manufacturing and process manufacturing. Discrete manufacturing follows instructions to create finished, assembled goods that can be dissembled back into their distinct parts.

While, process manufacturing follows recipes or formulas to create products that cannot be broken down at the end of the production cycle.

Food & beverages, pharmaceuticals, chemicals, paint & coatings, personal care & cosmetics, and many other industries practice process manufacturing to obtain their desired finished goods.

The food industry shoulders the responsibility of producing, processing, converting, preparing, preserving and packaging food items.

The food market is bifurcated into beverages, dairy, meat & poultry, bakery, convenience foods & snacks, fruits & vegetables, confectionery, frozen foods and many more categories.

With process manufacturing, it has become easy for food manufacturers to produce goods in bulk and package them individually in various quantities.

This blog will also discuss the functionality and benefits of process manufacturing ERPs in the food industry.

By 2026, the food and beverage market is expected to grow to $8,905.5 billion at a CAGR of 8.7%

Process Manufacturing in Food Industry

The practice of creating goods by combining supplies, ingredients or raw materials using a formula or recipe is called process manufacturing.

Finished good once created can’t be broken back into raw materials because there is often a change in the materials’ physical state due to processes like heating, mixing, blending, freezing, condensing and cooking.

Process manufacturing entails a continuous flow of successive steps, with the completion of one step leading to the start of the next step.

By taking the example of milk production, we can outline the sequential nature of process manufacturing.

Firstly, all the milk coming from different farms is collected and cooled at a particular temperature. Then, a separator splits lighter milk from heavier milk fat, to obtain cream and skimmed milk.

The next step is pasteurization, which involves heating the milk to a certain temperature and killing off any pathogenic micro-organisms.

Further, the milk is homogenized to even up the texture and then, it is stored for delivery to consumers or milk product companies. The sequence of steps in this process can’t be changed, as each of them serves a specific purpose.

In line with the above example, process manufacturing ensures that pre-defined production processes are repeated with the same level of precision every time.

The resulting standardization counts as one of the most important benefits of process manufacturing for the food industry.

Bulk manufacturing allows companies to negotiate better prices for raw materials, employ fewer workers and minimize production errors.

Thus, process manufacturing enables manufacturers to produce greater volumes at prices lower than their competitors.

Difference between Process & Discrete Manufacturing

The difference between discrete and process manufacturing is as clear as night and day.

Discrete manufacturing is undertaken with standard parts and components on assembly lines, whereas process manufacturing is pursued with recipes and formulas in batch processing.

In discrete manufacturing, processes like casting, forging, fabrication and extrusion are used. However, materials are mixed, heated, cooked and blended in process manufacturing.

The materials used in discrete manufacturing are counted individually as parts and the raw materials used in process manufacturing are variable according to the quantity of finished goods required.

The output of discrete manufacturing is measured in terms of individual units. On the contrary, process manufacturing output is identified by the measurement of weight or volume.

Process manufacturing is less defect-oriented, experiences fewer interruptions and improved quality control.

Types of Process Manufacturing

There are two types of process manufacturing: Batch processing and continuous processing. Companies with a well-established product line in the market have always been using continuous processing.

However, even these companies sometimes employ batch processing when they deal with seasonal demands or order-based production.

Both batch and continuous processing are well suited for food industry operations. Let’s understand the two concepts with their definitions:

Batch Processing –

Depending on the expected output, a certain amount of ingredients are processed through a sequence of one or more production steps.

The order of these steps is pre-defined and isn’t subject to change. The set amount of products received at the end of each sequence is a called a batch.

The production of any subsequent batch is only started once the processing of the ongoing batch has been completed.

Continuous Flow –

As the name suggests, materials are fed into the processing units without interruptions to achieve a continuous flow of finished goods.

In continuous flow, the manufacturer doesn’t wait for a batch to finish and raw material is fed and processed continuously to produce additional units.

This way, manufacturing units can run 24/7 to fulfil the demands of the customers. There are no breaks in time, sequence, substance, or extent.

As said before, continuous or batch processing can be undertaken by a food company, depending on its economies and preferences.

The decision can also be based on the quality and compliance requirements of your specific food industry vertical.

The batch method can offer better product traceability and improved product quality for specialty products and diversified product sets.

The continuous process supports large-scale production and allows companies to produce in large quantities.

ERP Software for Food Industry

In a detail-oriented environment such as food manufacturing, there is no space for human errors.

Therefore, food manufacturing companies should embrace automation to ensure the consistency and quality of their products.

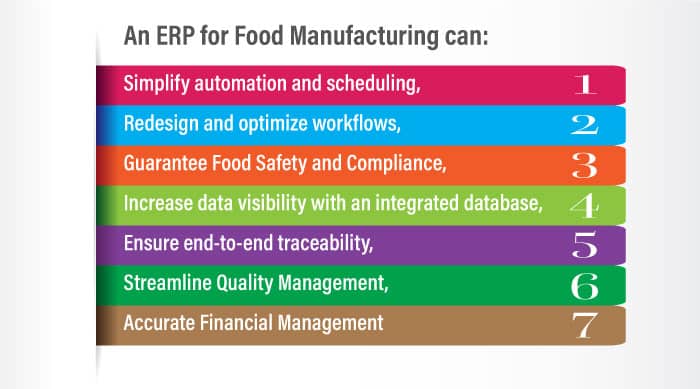

Notably, the implementation of an ERP system can enhance the results of process manufacturing. An ERP for Food Manufacturing can:

If you are a food manufacturer looking to automate, streamline, optimize and redesign your processes/workflows, you should consider implementing BatchMaster ERP for food industry.

We provide a holistic business solution with industry-specific modules for the food manufacturing and processing industry. If you wish to know more, please reach out to us.