Bill of Materials (BOM) Software

The blueprint of putting the product together from start to finish

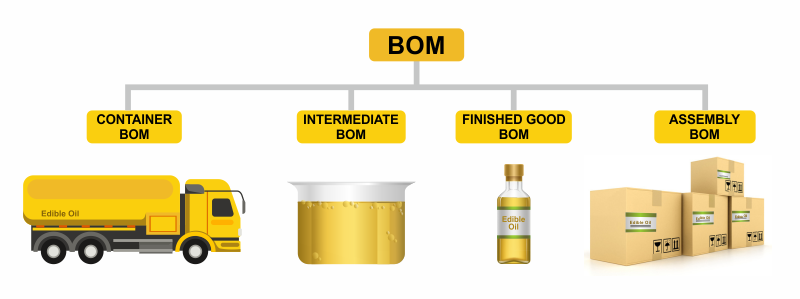

A Bill of Materials (BOM) is an integral component of the manufacturing process for the process manufacturing industries, and is used to link the formula with the finished goods or the intermediates stored in the inventory. Such is its importance that any slight inaccuracy in BOM can have consequences ranging from manufacturing delays, to the unit coming to a complete standstill. A bill of materials management software includes specific instructions on how to assemble the product right from conception through to the finished product ready to be shipped – including all the packaging and instruction, materials etc.

A manufacturing BOM, basically, is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product.

BatchMaster ERP | Bill of Materials

The BOM module in BatchMaster ERP system allows creating and managing BOMs quickly and easily. BatchMaster ERP allows the creation of three types of BOMs - Finished Good BOM, Intermediate BOM, and Assembly BOM, with ease. Fully integrating with the planning module of BatchMaster ERP, the BOM module provides a more accurate lead time in production scheduling.

The module comes with special functions such as ‘Release BOM’, ‘Resequencing’, ‘Toggle Units’, and ‘Sales Order Detail’, etc., and even facilitates displaying the exploded view of BOMs in an inverted tree form along with the details of sub-level items in a table, using BOM explosion functionality. Its utilities allow users to compare the current version of BOM with previous versions, view & revert to the prior version, and even purge the prior version.

Features of BatchMaster ERP’s Bill Of Materials Software

- Comprehensive Bill Of Materials functionality

- Supports multi-level manufacturing BOM

- Complete integration with the entire BatchMaster ERP solution

- Encloses top level BOM item

- Flexibility to define Fill Level in the desired unit of measurement

- Serves multiple packaging options

- BOM report to classify the top assembly items, assembly types, and status of the BOM components associated with the formulas

- Acting as Bill of Materials ERP Software, it caters to your needs for both Process (Formula BOM) and Discrete (Assembly BOM) Manufacturing

- Dispatches full view of the BOM hierarchy

- Single BOM allocation with multiple formulas

- Access and reuse previous BOM versions

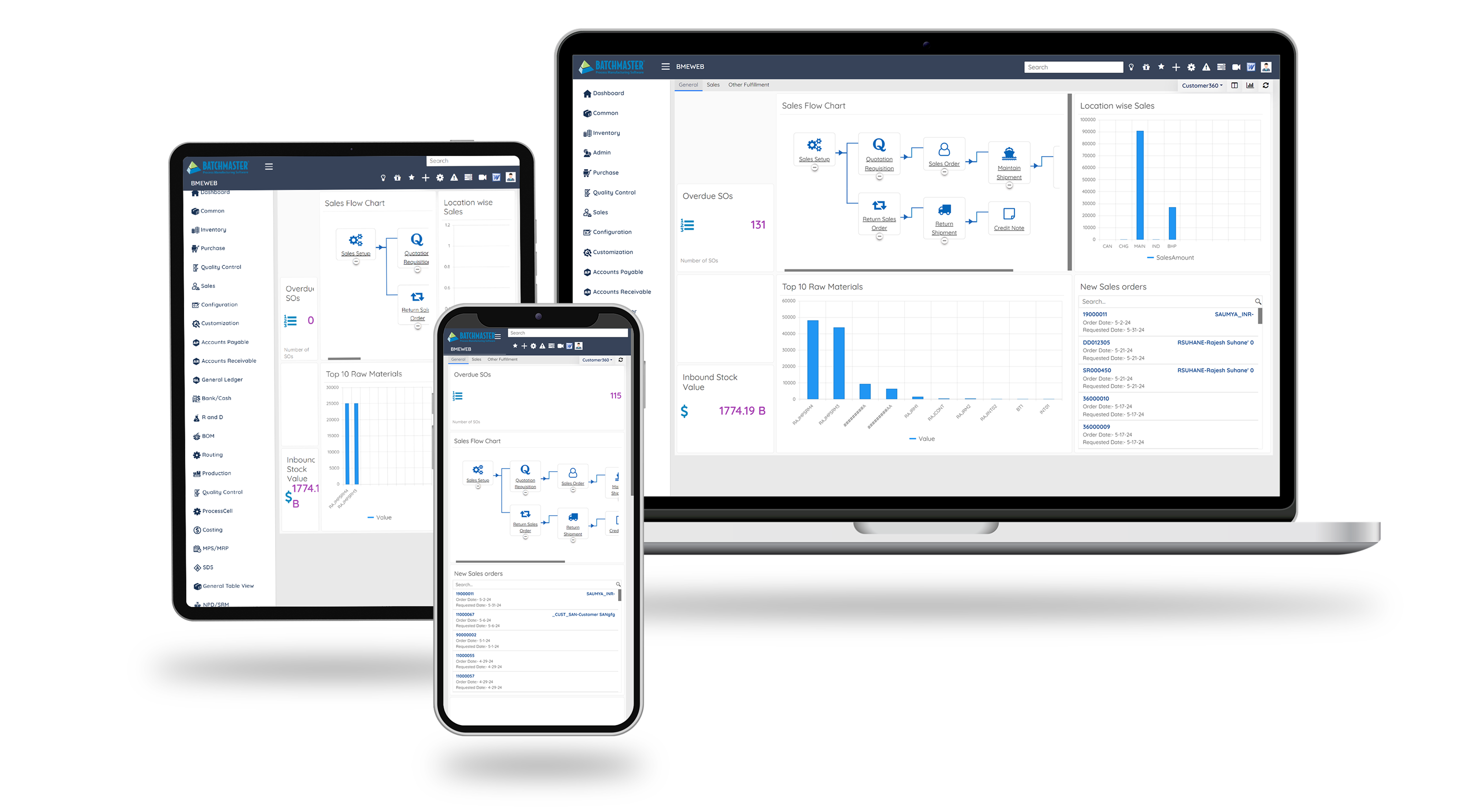

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs