Chemical Manufacturing ERP Software

What are the Challenges in Chemical Manufacturing?

In the constantly evolving landscape of specialty chemical manufacturing, companies face a multitude of complex challenges. One of the key issues is the rapid expansion of product varieties driven by shifting customer preferences. Simultaneously, the product life cycles are becoming shorter, adding to the complexity.

To thrive in this environment, manufacturers must strike a delicate balance between inventory investments, customer service, and operating costs, all while fostering innovation. They are continually in search of specialized, high-performance, and sustainable solutions.

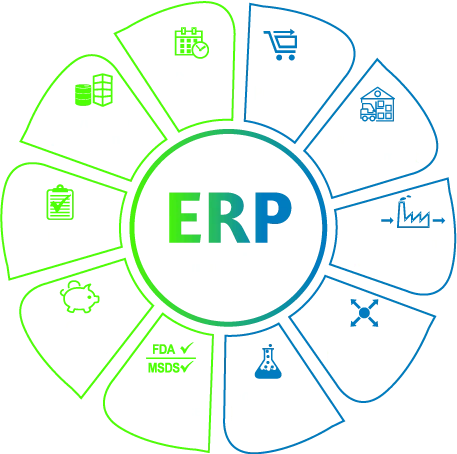

Chemical manufacturers turn to a chemical ERP that comes loaded with industry-specific modules and robust functionalities that help them effectively meet the challenges, standardize & automate business processes, and improve the supply chain efficiency.

A chemical industry ERP assists them with many things, including quality control at various stages, batch production with traceability, new product development, contract manufacturing, and meeting myriad compliance requirements, among others.

Experience the Power of Chemical Manufacturing Software

Chemical Industry

How BatchMaster Chemical ERP Helps Overcome Manufacturing Challenges

BatchMaster ERP for chemical industry is a comprehensive, industry-specific solution that helps chemical companies manage their entire production lifecycle—from formulation and inventory to quality control and regulatory compliance. Built for the unique needs of process manufacturers, it enables greater accuracy, batch traceability, and operational efficiency while ensuring adherence to stringent industry standards like GHS, OSHA, HAZMAT, and EPA. Whether you're producing agro chemicals, adhesives, dyes, or industrial chemicals, BatchMaster ERP gives you the control and insight needed to scale with confidence.

Key Capabilities:

- Advanced Formula Management: Fast, accurate lab calculations based on physical properties with separate costing for formulas and packaging materials.

- Flexible Manufacturing Support: Handles multiple packaging options, contract manufacturing, and new product development with ease.

- Regulatory Compliance: Helps meet stringent environmental and government regulations with built-in compliance tools.

- Seamless Integrations: Connects with SAP Business One, QuickBooks, Sage 50/100/200/300, and Tally.ERP 9 — no need to change your current financial system.

Solutions for Diverse Industries

Must-Have ERP Modules for Chemical Manufacturers

Key Features of BatchMaster ERP for Chemical Industry

- Formula security to safeguard Intellectual Property

- Compliance support for OSHA, EPA, ISO, and DOT

- GHS labeling compliance

- HAZMAT Bills of Lading, VOC, and SARA reporting

- Bi-directional lot traceability

- Vendor approval and management

- Stability testing

- Non-conformance and CAPA

- Complete traceability and costing of by-products and co-products

- Customizable COA (Certificate of Analysis) reports

- Formula design based on physical properties

- New product development and costing tools

- Inventory management software for real-time tracking

- Shelf-life and expiration date tracking

- Support for multiple units of measure

- Containerization capabilities

- Make-to-stock and make-to-order operations

- Material Production Scheduling (MPS) and Material Requirements Planning (MRP)

- HMIS support for worker safety

- Separate costing for formulas and packaging materials

Transform Your Chemical Business with BatchMaster ERP

Unlock Predictive Insights, Drive Success, and Achieve Amazing Results!

Benefits of BatchMaster ERP for Chemical Manufacturers

Chemical production software ensures compliance with industry standards and regulatory requirements, such as OSHA, EPA, and ISO. Read more

Our chemical industry software accelerates product innovation and competitiveness through simplified development processes. Read more

The ERP for chemicals automates production scaling with precise calculations, improving operational efficiency. Read more

Facilitates re-formulation based on potency and physical properties, ensuring product consistency and performance. Read more

ERP software for chemical industry provide real-time data for proactive decision-making and swift market responses. Read more

Chemical ERP software empowers manufacturers to enhance customer service, leading to improved retention and expansion.

Streamlining operations with ERP for chemical manufacturing boosts profitability by reducing costs.

Our chemical ERP solution supports the development of greener, sustainable products.

Frequently Asked Questions

A process-manufacturing ERP built for specialty and industrial chemical makers to manage formulation, batch production, quality, compliance, traceability, inventory, and costing—accelerating time-to-market while controlling risk and cost.

It helps identify and classify hazardous materials per OSHA/GHS, supports safe storage tracking, generates DOT transport documents and packaging labels, maintains disposal and training records, and centralizes compliance documentation.

The solution supports compliance with GHS, OSHA, HAZMAT/DOT, EPA, ISO, and broader cGMP expectations, with tools for SDS, GHS labeling, hazardous materials documentation, and audit support.

Advanced formula management includes physical-property-based calculations, potency adjustments, cost roll-ups, version control, and separate costing for formulas and packaging, enabling precise scale-up and reformulation.

Yes—BatchMaster manages NPD workflows, multi-stage synthesis, intermediates, by-products/impurities handling, and supports contract/outsourced manufacturing with documentation and quality controls.

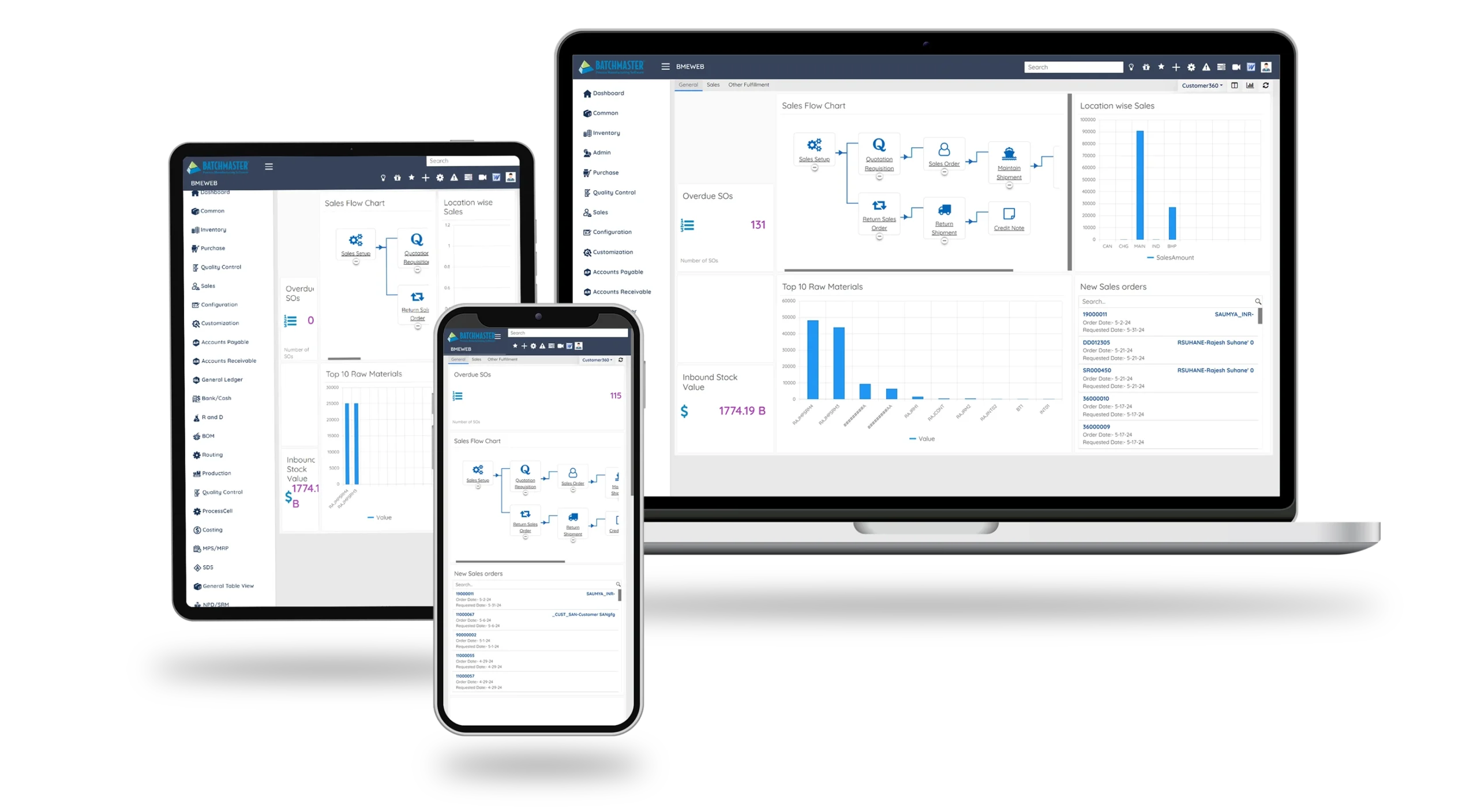

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs