Gone are the days when businesses tracked orders on paper ledgers and reconciled bank statements by hand. Today, most organizations rely on a suite of specialized tools, including accounting software for managing their finance function, inventory systems for stock control, payroll platforms for workforce management, and CRM solutions for customer engagement.

Some others increasingly rely on full-blown Enterprise Resource Planning (ERP) systems that tie it all together, bringing all the business functions together on the same platform. This evolution from manual processes to multiple, integrated business applications has been driven by the need for speed, accuracy, and real-time insight.

There’s another category, somewhere in between the first two, which finds itself facing a critical choice. In an age when data drives decisions, process manufacturers—whether in food, pharmaceuticals, chemicals, paints, or cosmetics—contemplate if they should stick with a standalone accounting software, or invest in a full-fledged ERP system. And this sets the stage for our blog on this ultimate showdown: ERP vs. standalone accounting software.

As businesses outgrow basic bookkeeping, the debate over ERP vs accounting software intensifies. This blog describes the two of them, unpacks the features of ERP vs standalone accounting software, the cost comparison: ERP vs accounting software, and the benefits of ERP over accounting software, ultimately showing why an ERP typically delivers more value for complex manufacturing environments. Read on:

To begin, what’s a standalone accounting software?

As the name suggests, a standalone accounting software, or simply an accounting software, zeroes in on your company’s financial heartbeat. It keeps track of all the financial transactions of your business, while logging in every sale, recording every expense, and meeting financial audit requirement.

Built specifically to streamline the work of your finance teams, these tools handle the day-to-day bookkeeping that keeps your books balanced and regulators satisfied.

Its key capabilities often include:

- General Ledger & Journal Entries: Recording revenues, expenses, assets, and liabilities.

- Accounts Payable & Receivable: Automating vendor bills, invoices, and collections.

- Bank Reconciliation & Cash Management: Matching statements to ledgers with minimal effort.

- Financial Reporting: Instantly generating balance sheets, profit & loss reports, and cash-flow statements.

Accounting software—prime examples being QuickBooks, Tally and Zoho Books—offer a number of benefits to your business, namely accurate decision making, reduction in labor cost, automated transactions etc. And while they are rapid to deploy and simple to use, standalone accounting software can leave growing manufacturers stuttering when production ramps up.

Without built-in inventory or scheduling ties, you end up patching together spreadsheets and manual reconciliations, losing precious time and risking costly errors.

And what’s an ERP system?

ERP software have quickly become a strategic priority for businesses world over. At its core, an ERP is a unified business management platform. It’s an integrated suite of applications that collects, stores, manages, and interprets data across every major function of an organization, from finance and accounting to production and quality management.

A true process-centric ERP system goes beyond basic bookkeeping or inventory tracking, and delivers modules tailored to process manufacturing needs, including:

- Production Planning & Scheduling: Master Production Scheduling (MPS), Material Requirements Planning (MRP), and shop-floor execution ensure your lines run on time and in full.

- R&D & Formulation: These capabilities empower you to innovate and control formulations with integrated recipe management, automated version tracking, and embedded quality and cost analyses.

- Inventory & Warehouse Management: Real-time lot and serial number tracking, expiration date controls, and multi-warehouse support keep raw materials and finished goods where they belong.

- Quality Control & Compliance: An embedded QC module offers in-process inspections, non-conformance (NC) handling, and corrective & preventive actions (CAPA). Additionally, ERP ensures strict adherence to regulatory requirements by providing detailed traceability throughout every production stage.

- Procurement & Supplier Management: From purchase order creation to supplier performance evaluations and seamless invoice matching, you gain full control over your supply chain.

- Finance & Accounting: All the familiar capabilities of standalone accounting software such as general ledger, accounts payable/receivable, bank reconciliation, and financial reporting are enhanced with cost accounting, budgeting, and multi-entity consolidation.

- Sales & CRM: Order management, pricing, customer analytics, and service-contract tracking live alongside operational data for a single source of truth.

By integrating these modules, an ERP system creates a single source of truth that eliminates data silos and fosters collaboration across departments. And because every ERP module shares the same database, actions in one area instantly impact the rest.

For example, an invoice posted by finance automatically updates inventory levels; and a completed quality inspection flags any non-conformance for CAPA workflows.

This real-time integration delivers streamlined processes, improved productivity, enhanced visibility, and reduced costs and risks, thus making ERP software an indispensable tool for process manufacturers in food, pharma, chemicals, paints, and cosmetics.

Features of ERP vs Standalone Accounting Software

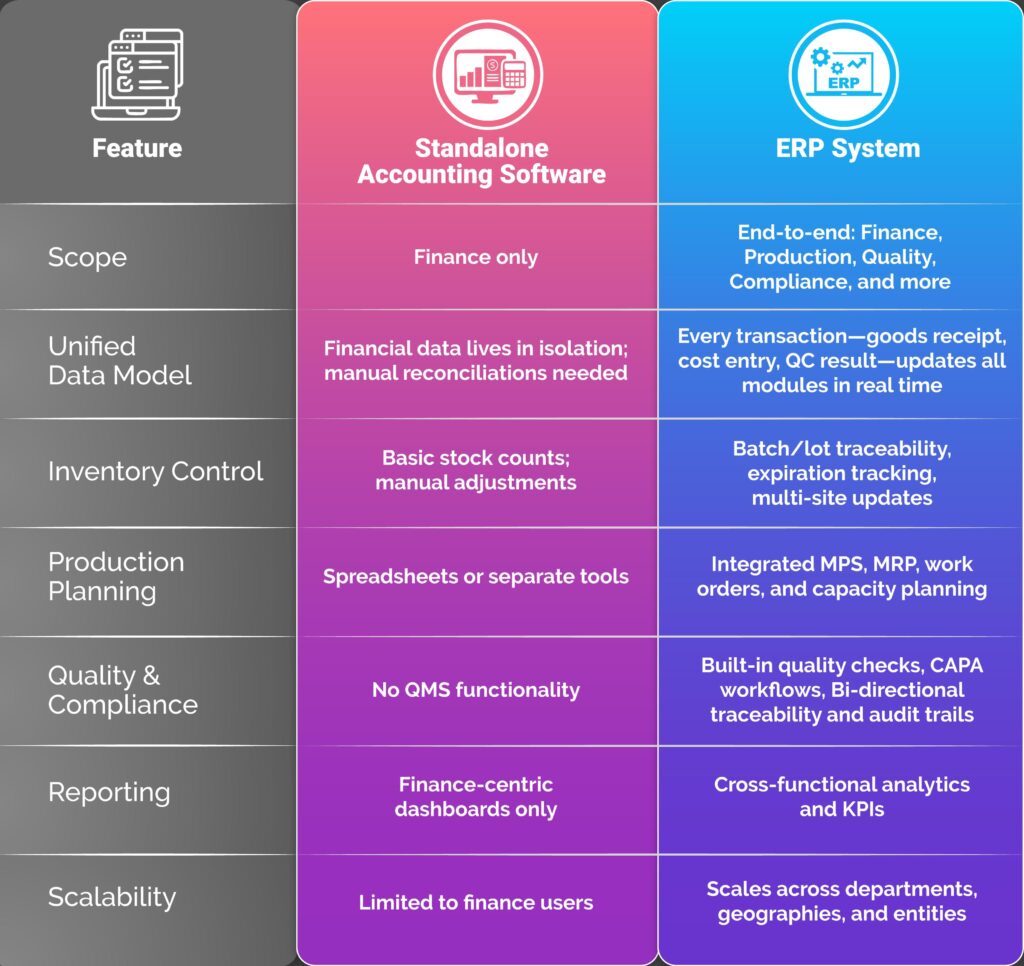

Growing manufacturers switch from standalone accounting software to ERP systems because only an ERP can deliver end-to-end control, real-time data, and deep operational insight. Here’s how their features stack up:

By unifying data, automating core manufacturing functions, and embedding quality workflows, ERPs eliminate manual handoffs and documentary silos to unlock efficiencies and insights that accounting software alone simply can’t match.

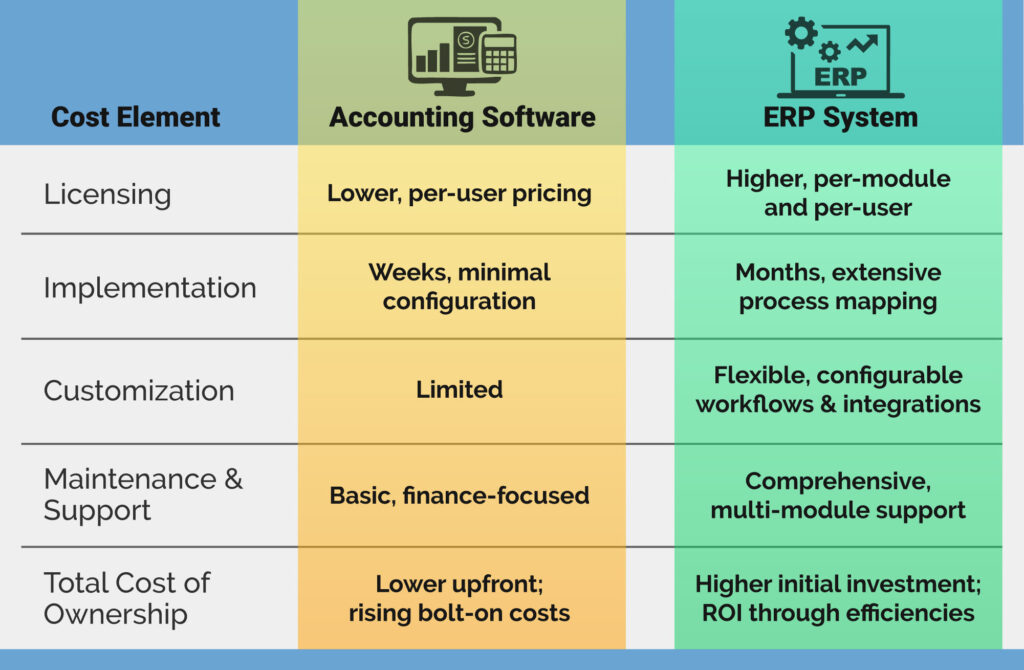

Cost comparison: ERP vs Accounting Software

Standalone accounting software appeals to tight budgets, but its hidden costs—spreadsheets, manual reconciliations, compliance fines, and production inefficiencies—quickly add up. An ERP’s initial investment often pays for itself in reduced waste, faster time-to-market, and stronger regulatory compliance.

Benefits of ERP over accounting software

For process manufacturers, who operate within tight margins, rigorous regulations, and complex formulations, the advantages of a full ERP system over standalone accounting software are many:

End-to-End Visibility:

Track every transaction, from raw material receipt through batch yields to finished-goods shipment, in a single interface, eliminating blind spots and data silos.

Operational Efficiency:

Automated MPS/MRP and integrated QC workflows remove manual planning, recipe calculations, and quality bottlenecks, driving smoother production cycles.

Complex Recipe & Change Control:

Manage formulations, by-products, yield calculations, and change approvals natively within the system: capabilities an accounting package simply can’t provide.

Safety & Compliance:

Full audit trails for inspections by OSHA, EPA, FDA, and other bodies in regulated industries. Embedded SDS and HMIS/WHMIS at every stage to safeguard safety while keeping pace with tightening regulations.

Optimized Cash Flow & Costing:

Real-time inventory forecasting and precise batch-level costing accelerate order-to-cash cycles and improve working-capital management.

Scalable, Collaborative Workflows:

Role-based access and shared data unite finance, production, quality, procurement, and R&D teams—enabling you to add plants, product lines, or geographies without reinventing processes.

These benefits of ERP over accounting software ensure process manufacturers meet stringent standards, maintain product consistency, and respond rapidly to market demands—capabilities a standalone accounting solution simply can’t match.

In sum

Choosing between ERP vs accounting software is not just a technical decision, but a strategic one. While an accounting software meets basic financial needs, an ERP system transforms your entire operation with integrated planning, quality management, and supply chain control.

For process manufacturers seeking sustainable growth, the features of ERP vs standalone accounting software, the cost comparison: ERP vs accounting software, and the benefits of ERP over accounting software make it clear: invest in ERP to future-proof your business.

Ready to streamline your process manufacturing operations with an ERP that spans finance, production, quality, and supply chain? Your search ends here. Get in touch for a no-obligation discussion, and learn how our ERP solutions can offer holistic help to your business.