ERP Module for Production/Batch Processing

Easily streamline and quickly ramp up production

Easily Streamline and Quickly Ramp up Production

Today’s enterprise world faces increasingly complex job order processes with orders consisting of component parts, customized configuration, sizing specifications and frequent customer requirement changes. BatchMaster provides a comprehensive batch manufacturing software that consists of Production Module which virtually consolidates batch information, increases efficiency and reduces gap between software and actual operations.

BatchMaster's matchless SuperBatch™ and Runs functionalities always keep you a step ahead in your capabilities and processes. SuperBatch allows you to launch your intermediates and finished good together in a single batch, yet in the required chronological order, while Runs allow your batch production during a continuous period of operation to be achieved in individual as well as independent workable batches.

SuperBatch concept has been developed specifically for multi-level batches. It eases out the process by creating multiple batches, required for production of finished good, in a single go. The system than executes them in the right chronological order ensuring availability of intermediate of one level before moving on to the next level. Thus, using BatchMaster ERP, manufacturers do not have to manage data records for the intermediate production batch and finished goods production batch separately, instead all of the data is available together under one single record.

Features that sets BatchMaster ERP’s Production Module apart:

- Supports batch process manufacturing

- Supports Advanced Models such as SuperBatch™ and Runs

- Supports Contract-manufacturing, loan-licensing, own-manufacturing and such models

- Supports both make-to-stock and make-to-order manufacturing

- Anytime Batch Sizing Wizard (by material, shortage, finished goods target and more)

- Full and Partial Closing allows for immediate shipment of urgent orders

- Drag & Drop advanced batch production scheduling and multiple operational dashboards

- Separate definition and creation of batches with Allergen, Kosher or Halal ingredients

- Handles Fixed Input/Variable Output Batches or to say 'Private Label' Outputs

- Generates Supplements, Ingredient & Nutritional labels or Allergen Statements

- Supports rework of excess product into WIP, alternate finished goods, or even By-product for resale

- Batch Inspection and quality tests to ensure quality and consistency

- Sizes batches by finished good’s weight /volume or available materials

- Identify critical materials

With BatchMaster ERP’s Production Module you can::

- Streamline complex multi-level production process

- Manufacture as per available resources and regulatory guidelines

- Reduce wastage

- Control losses and costs

- Produce expected yields

- Quickly scale up production

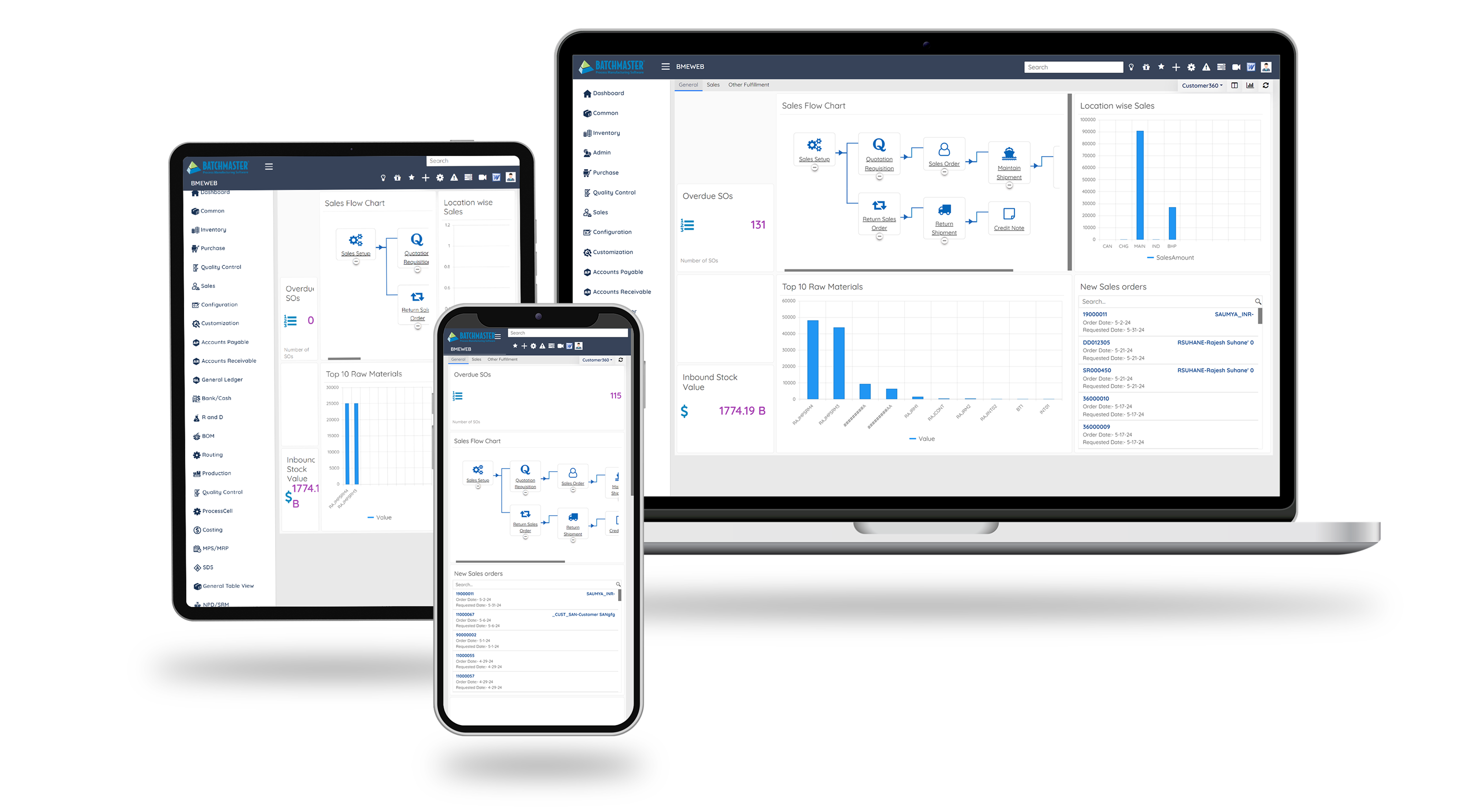

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs