BATCHMASTER ERP for Fuel & Lubricants

What are the Challenges in Fuel & Lubricants Manufacturing?

Rising global demand, volatile prices, increasingly stringent environmental regulations, meeting modern-day requirements of good quality grease, synthetic lubricants etc. puts enormous pressure on fuel and lubricants manufacturers.

It demands tight control over processes and data flow, ensuring appropriate changes to formulas and procedures for monitoring viscosity, viscosity index, resistance to corrosion and oxidation, aging or contamination, etc., is crucial to regulate quality. Optimizing processes on operating sites of kerosene, compressed natural gas (CNG), and engine oils, and industrial lubricants is the key to overcome the setbacks due to hair-line thin profit margins.

Would you like to learn more about our ERP for fuel & lubricants?

Food Industry

Why Fuel & Lubricants Manufacturers Need a Tailor-made ERP?

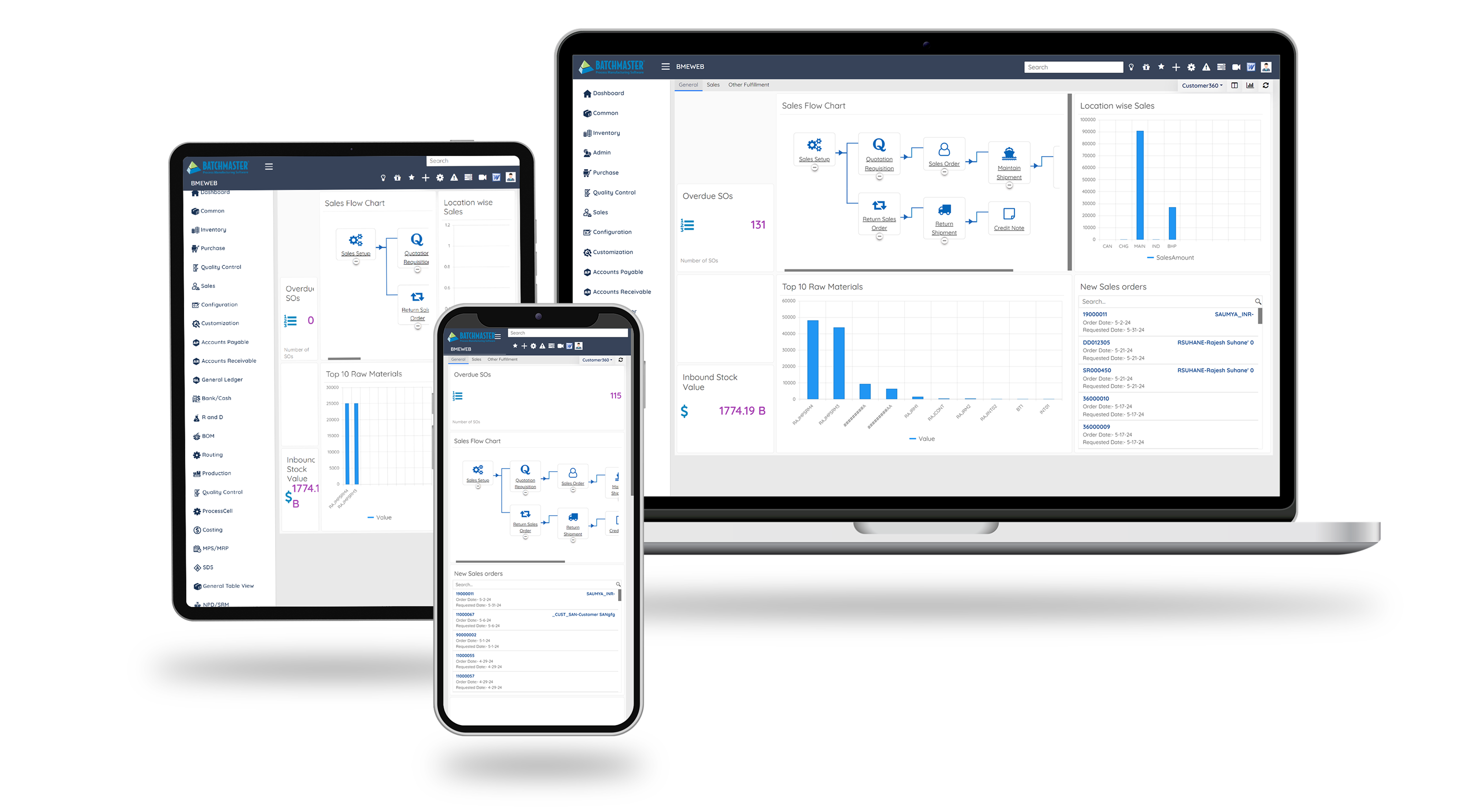

BatchMaster ERP is one-stop solution that streamlines operations, manages hundreds and thousands of formulas, helps modify or substitute a chemical in formula along with securing the original formula, and assures adherence to workplace safety standards. With excellent planning and dashboards for detailed reports, this ERP software for chemical industry offers real-time information, demand, supply and all other information at your fingertips. Replacing error-prone manual processes to system-operated finance and accounting, it speeds up cash-to-cash process. Moreover, greener and cost effective substitutes can be worked upon in laboratory without all the tedious calculations to achieve targeted physical properties and cost.

Our products have a proven integration to SAP Business One, Sage 50/100/200/300, QuickBooks, and Tally.ERP 9 which means you can easily upgrade to BatchMaster without having to shun your financial software.

Transform Your Fuel & Lubricants Manufacturing with BatchMaster ERP

Unlock Predictive Insights, Drive Success, and Achieve Amazing Results!

Key Features of ERP Software for Fuel & Lubricants Manufacturing

- Formula design based on physical properties analysis like viscosity and density

- Formula security to support Intellectual Property Rights (IPRs)

- Supports API, OSHA, GHS, EPA, ISO, compliance requirements

- HAZMAT bills of lading, VOC, and SARA reporting

- Automatic SDS and label generation

- HMIS support for safety of workers

- Containerization for liquids, and semi-solid lubricants

- Bi-directional lot traceability

- Vendor approval and management

- Stability testing

- Non-Conformance and CAPA

- Complete traceability and costing of by and co-products

- Customized COA (Certificate of Analysis) reports

- Separate costing of formula and packaging materials

- New product development and its costing

- Warehouse management and real-time tracking of inventory movement

- Material substitution for additives and emulsifying agents

- Supports multiple units of measure

- Make-To-Stock and Make-To-Order operations

- Material Production Scheduling (MPS) & Material Requirement Panning (MRP) for optimum raw material procurement and order processing

Benefits of BatchMaster ERP for Fuel & Lubricants Manufacturers

- Increased operational efficiency

- Maximized asset uptime

- Optimized parts utilization to assure uninterrupted production flow

- Avoids unplanned shutdowns due to crude oil or ingredient chemicals shortage.

- Effectively helps to meet regulatory requirements

- Re-formulation based on potency and physical properties

- Real-time information for pro-active decision making

- Assure 'greener' products

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Brochures

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs