Mastering allergens, rather than merely managing them, is crucial for food manufacturing businesses in order to safeguard consumer health and comply with strict food safety regulations. This blog offers a comprehensive overview of effective allergen management, highlighting its critical importance in the industry.

It also provides insights on practical strategies, contemporary tools, and best practices to mitigate allergen risks and achieve compliance. Read on.

Overview

Food allergies affect millions of people worldwide. Therefore, even a small mistake involving allergens can have severe repercussions for your food manufacturing business, as even a single hidden allergen in your product can result in serious health risks, damaging consumer trust, and bringing forth costly recalls.

Take this for instance: somewhere a family is looking forward to a quiet meal, oblivious to the fact that a hidden allergen has already slipped through your process and made its way to their meal. And moments later, an allergic reaction to one of its members turns that calm into panic.

Such scenarios are far from being hypothetical. In fact, they occur when allergen management is handled too carelessly or casually. That’s why mastering allergen managementis no longer optional. As a matter of fact, it isn’t just a legal requirement in this age of fast-paced information and consumer awareness, but a moral one too.

And Luckily, There’s a Practical Solution to This Problem!

By implementing an effective food safety ERP software, you can get rid of your cumbersome manual tasks, and error-prone processes with streamlined, automated and traceable workflows, thus completely transforming your food manufacturing processes, including allergen management.

This blog offers all the insight you need into allergen management, explaining how to identify allergens, evaluate related risks, address compliance requirements, and leverage ERP solutions like BatchMaster Food ERP to help you protect your customers, preserve your brand’s reputation, and ensure your business runs seamlessly.

Let’s First Understand Allergens and Their Regulatory Framework

Allergens, primarily proteins, are substances that provoke immune responses in individuals with sensitivities. In the United States of America (USA), the Food and Drug Administration (FDA) identifies eight major allergens: milk, eggs, fish, shellfish, tree nuts, peanuts, wheat and soybeans, while Food Allergy Research & Education (FARE) adds sesame as the ninth member of this “Big 9” club.

Then there’s the 2006 Food Allergen Labeling and Consumer Protection Act (FALCPA), which targets the “Big 9” as those responsible for 90 percent of severe reactions, mandating manufacturers to label these clearly.

Additional U.S. laws, such as the Federal Meat Inspection Act (FMIA), Poultry Products Inspection Act (PPIA) and Egg Products Inspection Act (EPIA), recommend that food manufacturers declare products derived from these allergens. The Food Safety Modernization Act (FSMA) of 2011 further mandates that food manufacturing companies implement allergen control measures throughout their operations.

In the UK, going beyond the Big 9, legislation expands this list to 14 common allergens. There, the food businesses must also declare celery, cereals containing gluten, lupin, molluscs, mustard and sulphur dioxide.

Food Allergens Predominantly Appear Through Three Main Pathways:

- Ingredients deliberately added, like peanut flour or whey protein.

- Hidden allergens in processing aids or additives.

- Cross-contact, where trace allergens transfer via shared storage or equipment.

What is Allergen Management?

To put it in simplest of terms, allergen management is a dynamic system of set policies and procedures that govern the handling, storage, processing, and transport of allergenic ingredients from raw materials to finished products.

The process starts with identifying every possible allergen within your supply chain and separating high-risk materials during storage and production to avoid cross-contact. Next, it moves to providing training to the staff through continuous education to implement effective cleaning protocols that eliminate residues.

Finally, it concludes with precise labelling and transparent communication to ensure consumers are fully aware of the contents in each product they purchase. This way, an effective allergen management program continually evolves to account for updates in ingredients, processes, and regulations, becoming a core aspect of daily operations and a critical component of due diligence for food manufacturers.

Why Allergen Management Matters?

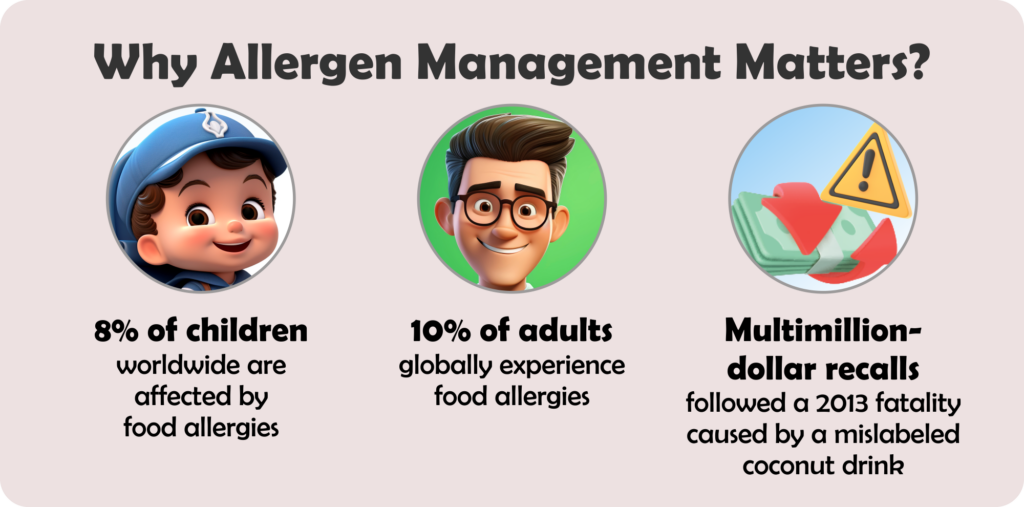

As mentioned above, food allergies are constantly on the rise, posing a significant public health concern. According to the World Health Organization (WHO), food allergies affect more than 10% of the general population worldwide.

When broken down further, approximately 8% of children and 10% of adults experience these reactions. Out of these, severe allergic reactions such as anaphylaxis can even have life-threatening consequences.

In 2013, Australia experienced the heart-breaking loss of a young boy after he consumed a mislabelled coconut drink containing undeclared cow’s milk. This tragedy led to extensive product recalls and stricter reporting regulations in the Australian state of Victoria.

In addition to the human aspect, the consequences of allergen mismanagement can include hefty financial and reputational damage. Recalls can incur multimillion-dollar costs, and regaining consumer trust can be a daunting task.

Thus, from raw material procurement to final packaging, each step of production demands meticulous risk management, hence underscoring the importance of effective allergen management.

Managing Allergens at Key Control Points

Ensuring effective allergen control starts with the basics: managing ingredients as soon as they arrive at your facility. You must thoroughly check allergen declarations and batch certificates from suppliers, and designate dedicated, clearly marked zones for allergenic materials. This helps avoid mix-ups with non-allergenic stocks, setting a solid foundation for safe handling throughout your food manufacturing operations.

Next up, how you structure your production schedule is equally important step in managing allergens at key control points. Grouping batches that contain allergens into a single run and following immediately with a thorough sanitation cycle ensures minimal cross-contact. Furthermore, documenting each changeover reinforces the effectiveness of your process.

Lastly, accurate packaging and labelling complete the process by tying everything together. Before products leave the production line, barcode scanning and automated label verification ensure the correct allergen information is displayed on every pack—whether it’s “contains” or “free from”—and aligns perfectly with your recipe and regulatory standards. Altogether, these measures create a reliable framework for managing allergens effectively.

BatchMaster Food ERP Supports Allergen Management

To begin with, BatchMaster ERP for Food Industry transforms the way food businesses manage allergens by addressing the shortcomings of traditional methods like spreadsheets, paper logs, and other unconnected systems.

Through automated workflows, centralized data, and real-time alerts, allergen management with ERP can eliminate guesswork and ensure that every step, right from purchase order to product shipment, adheres to best practices.

As the best ERP software for allergen management, BatchMaster Food ERP for FDA allergen compliance consolidates recipes, ingredients, and allergen declarations into one robust platform, serving as a single source of truth for businesses.

BatchMaster ERP’s specialized modules equip your business with outstanding solutions for food industry allergen control:

- Formula & Recipe Management flags allergenic ingredients in real time as you build or adjust recipes. Any substitution, such as replacing almond flour with wheat flour, automatic ally triggers label updates and recipe revalidation.

- Bi‑Directional Traceability empowers with insights into what your goods encounter throughout the manufacturing process and their precise destinations once they are ready for shipment. This capability tracks every ingredient batch from supplier to production line and finished goods back to customers, enabling swift, targeted recalls when needed.

- Production scheduling groups all allergen‑containing runs together and automatically schedules validated sanitation between runs to prevent cross‑contact.

- Production Labeling capability generates ingredient and allergen statements/labels for every pack, ensuring “contains” statements match the current recipe. These statements can be generated on demand and maintained in history logs including recipe approvals and batch job changes, for auditing purposes.

To Sum Up

More than good intentions, effective allergen management demands actions. It requires a methodical approach that spans people, processes and technology. From identifying hidden allergens to enforcing validated cleaning protocols, every step matters in the journey. And as food safety challenges grow, your food manufacturing business needs a partner in allergen compliance and control.

BatchMaster ERP delivers purpose-built modules to help you master allergen risks, meet global standards, and protect your customers. Backed by over four decades of industry expertise and more than 3,000 successful implementations, our agile, web-based solution ensures enhanced accessibility, real-time insights, and automated workflows, making it the food safety ERP software you can truly rely on.

Take the next step in your allergen management journey by contacting us today to schedule a personalized demo of BatchMaster Food ERP, and see how we can help you build & run safer and more compliant food manufacturing operations.