ERP For Wine Manufacturing Industry

What is the Role of ERP Software in the Wine Industry?

“Wine is a bottled poetry”

“Wine is an exquisite beverage that delights the senses.” Each drop tells a story of how perfectly the earthy fruit- grape is transformed into a masterpiece of aroma and taste. Sip by sip, it unveils the artistry of nature and human craftsmanship, leaving an unforgettable impression on the heart and soul.”

Overview

Winemaking is a centuries-old art of transforming grape juice into wine. However, the journey from vineyard to wine glass presents its share of challenges. Like any other beverage business, wine manufacturing also involves a laundry list of meticulous processes.

It starts from tending the vines, continues with the process of harvesting them, and then finishes with processing and bottling. Additionally, these main processes require the completion of several important tasks. These tasks include checking quality, managing suppliers, following regulations, and storing goods.

Would you like to learn more about our Wine ERP Software?

Food Industry

And every process involved in wine manufacturing requires precise guidance and extreme control for their successful execution. Due to this reason wineries are turning towards implementing an ERP System that streamlines the management of complex processes.

This is significantly contributing to their success! Before we proceed, let's look back and understand the grape journey from vineyards to the processing assembly.

Introduction

There’s a long-standing story that talks about the manufacturing of wine for the first time. The narrative takes us to ancient times, where a Princess in Persepolis unknowingly consumed fermented grape juice from a jar.

Rather than suffering adverse effects, she remained alive but felt giddy and intoxicated. Intrigued by this unexpected outcome, she shared her discovery with the King, and thus, the tradition of wine creation began.

Though it’s difficult to determine the historical accuracy of this tale. But this undeniably showcases the ancient existence of this accidentally fermented drink. Slowly, people from different cultures recognized the value of “wine”.

Over time, diverse cultures came to recognize the value of "wine," originally known as "Grape Juice." Knowledge of winemaking gradually spread across various regions, becoming an art form passed down through generations. As centuries passed, the art of winemaking evolved significantly.

Steps in Winemaking

Grapes are widely recognized as the primary raw material used in wine manufacturing. Their quality significantly influences the final character and excellence of the wine produced. As such, grape production stands as the fundamental and critical step in winemaking.

Throughout the years, winemaking has undergone numerous changes, yet the process remains inherently complex. Certain aspects of winemaking depend entirely on the effects of nature, going beyond our control. Production of grapes is a quintessential example of it.

White wine and red wine are the two primary types of wine, made from green or yellowish grapes and black grapes, respectively. The manufacturing process of white wine involves separating the grape juice from the skins before fermentation, resulting in its light colour.

On the other hand, red wine is made by leaving the grape skins in contact with the juice during fermentation, imparting colour, and flavour to the final product.

The infographic depicts the steps of wine production. It begins with harvesting the grapes from the vineyard, followed by crushing and pressing to release the juice. The extracted juice is then fermented, where the sugar in the grapes is converted into alcohol. After fermentation, the wine undergoes clarification to remove any solid particles.

Subsequently, the aging process takes centre stage. This process is considered crucial and influential in winemaking. This stage significantly impacts the wine's final character and quality. Aging is commonly performed in oak barrels due to their ability to impart unique flavours, aromas, and textures to the wine. As the wine interacts with the oak, it absorbs compounds from the wood, ultimately enhancing the overall profile of the wine.

“Wine matures gracefully in these barrels to get the tag of finely aged wine and become an esteemed choice among the collectors.”

Finally, the wine is bottled and delivered to the market.

Challenges Wine Manufacturers Encounter

“The pleasure of tasting the finest wine is often a direct reflection of the immense efforts invested”.

Crafting truly exceptional wines requires an immense amount of hard work, dedication, and attention to the details throughout the entire winemaking process. From carefully managing the vineyards to the final bottling, winemakers and their teams must perform each step precisely. To create wines that bring joy to those who savour them.

However, wine manufacturers often encounter obstacles that obstruct streamlined and smooth production. One common challenge is the unpredictability of climate conditions. Extreme temperatures and excessive rainfall significantly impact grape quality, making it difficult for winemakers to maintain consistency and achieve desired flavours.

Moreover, quality control plays a pivotal role in wine production. The industry operates under strict regulations and guidelines set by global, national, and local regulatory bodies. These rules dictate permissible production strategies, such as the controlled use of additives and processing aids. This helps manufacturers ensure the quality and safety of the wine.

Yet, adhering to these limits becomes a challenging task for the manufacturers who struggle with visibility into their operations.

In addition to the challenges mentioned above, wine manufacturers also face labour shortages and disrupted supply chains. As the wine industry is labour-intensive, finding skilled labour becomes increasingly difficult.

Trained personnel, especially experienced viticulturists and winemakers are essential for maintaining the quality and consistency of wines. Labor shortages can hinder production efficiency and potentially affect the overall quality of the final product.

Furthermore, Wineries heavily rely on a steady flow of materials like bottles, corks, and labels, as well as equipment and machinery. Disrupted supply chains, caused by various factors such as varying season, transportation issues, or geopolitical tensions, can also pose significant challenges.

These interruptions can lead to delays and production bottlenecks, affecting the timely release of wines and potentially harming the winery's reputation.

Given the industry's complex challenges, wine manufacturers find investing in technological advancements unavoidable and essential for their progress. While we cannot control climatic fluctuations, but we can definitely address other issues through technology like automation.

This is where “ERP for wine industry” turns the story to success…

Transform Your Wine Manufacturing Business with BatchMaster ERP

Unlock Predictive Insights, Drive Success, and Achieve Amazing Results!

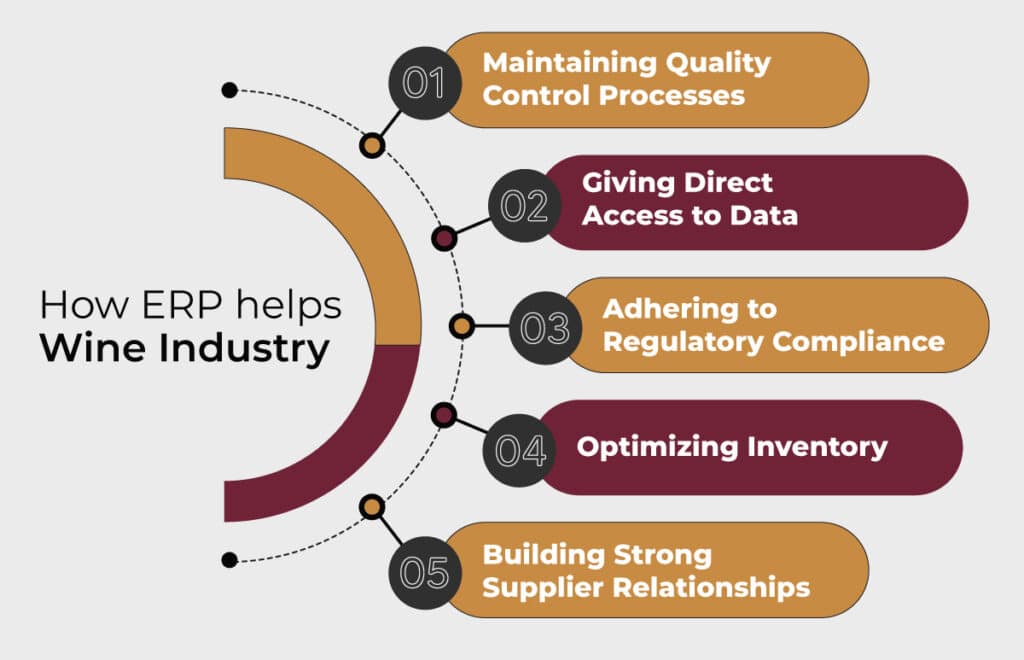

How ERP helps Overcome Winemaking Challenges

The Enterprise Resource Planning System has emerged as a powerful technological solution for process manufacturing industries, particularly in the wine industry. Its comprehensive approach assists manufacturers in addressing the complexities of production from start to finish. To understand how ERP benefits wine manufacturing industries, keep reading!

Efficient Planning & Production Scheduling

This is the crucial area where ERP proves beneficial. Crushing, fermentation, and pressing processes are the common bottlenecks in the wine industry. To streamline these processes, production speed needs to be constant with decreased start stop actions.

Furthermore, the process of crushing grapes is intricate, where precise timing holds utmost importance. Grapes being delicate, the time gap between picking and crushing must be minimal to prevent spoilage.

Thankfully, an ERP comes to the rescue. ERP systems provide tools for scheduling and organizing every process involved in winemaking. By considering factors such as grape ripeness, fermentation vessel availability, and winery capacity, it helps in creating accurate and efficient production schedules.

Optimizing Inventory

Efficient inventory management is vital for wine manufacturers to enhance production efficiency. ERP offers real-time visibility into inventory levels, enabling manufacturers to track stock levels and prevent overstocking or stockouts.

This minimizes carrying costs and reduces waste. Furthermore, consolidating complete inventory data at a centralized location, an ERP makes it easily accessible for everyone anytime, anywhere. This further facilitates manufacturers in taking informed decisions regarding inventory refilling and procurement.

Besides inventory, an ERP keeps manufacturers ahead in the warehouse operations too. Its integration with the technologies like barcode scanning and RFID tags, enable quick and precise identification of items. This leads to establishing an efficient material handling process.

Maintaining Quality Control Processes

The quality of grapes significantly impacts downstream processes, particularly fermentation. Understanding the quality parameters of incoming grapes is essential for making corrective adjustments and tailoring processing methods. The standard practice involves processing grapes as they are received, with basic parameters such as sugar content (Brix/Baume), pH, and titratable acidity (TA) being measured.

Here, ERP solution acts as an exemplary quality controlling solution. By capturing real-time data on grape quality parameters, it helps wine manufacturers to have a comprehensive view of the incoming grapes. By spotting quality variation in the grape batches, manufacturers can make decisions actively.

That’s not all, an ERP allows inspecting fermentation, aging, processing, and bottling too. User-defined number of samples can be drawn to ensure the quality of the wine. Various quality checks can be applied to meet the desired targeted characteristics of the wine.

Giving Direct Access to Production Data

Winemaking is a delicate process, where variations during processes like fermentation, clarification, racking, or aging can impact wine production. Additionally, crucial questions like when did the fermenting of the grapes start? Have we pressed the grapes that entered the production unit? Since how long a certain oak is under aging? etc.

ERP system helps you answer all such questions by easily providing you a bird’s eye as well as granular view of your facility. This empowers manufacturers to make informed decisions confidently and maintain the quality of their wines.

Adhering to Regulatory Compliance

Compliance with regulatory standards is crucial for wine manufacturers due to varying rules and regulations across different states. ERP's compliance feature helps manufacturers ensure adherence to FDA and other regulatory authorities.

The system also keeps track of licenses and certifications, preventing potential legal fines. Additionally, ERP enables-

• Making dynamic adjustments to formulas or recipes to meet labelling requirements.

• Generating nutritional labels compliant with FDA regulations.

Managing Pickups & Shipments

Effective pick-ups, packing, and tracking of shipped products can significantly influence your business while also prevents losses. Implementing a winery ERP software automates complex processes like picking, bottling, packaging, etc. and benefits wineries on multiple fronts such as-

• Bottling in different sizes

• Benchmarking of bottling speeds

• Reducing unnecessary product movement and stoppages

• Proper labelling in standard formats, etc.

Lastly, as a result of all the above-mentioned factors, the entire supply chain undergoes streamlining, ensuring seamless production without any disruptions.

How BatchMaster is a One-Stop Solution for You

Today, one of the key requirements of wineries is the high level of automation and real time monitoring for production control. Good production control maximises the efficiency of labour, materials, and water while increasing production speed and quality.

Whether it is for refrigeration control, fermentation profiles, bottling, or other winery processes, brewery ERP software allows for 24-hour control. This decreases variability between products and maximises desired quality parameters, increasing the overall quality of the wine.

If you are a wine manufacturer seeking such a compatible and competent solution, look no further than BatchMaster ERP.

Our software provides the effectiveness you need to streamline your operations. Don't hesitate; contact our team of experts today to explore how BatchMaster ERP can elevate your wine manufacturing process.