BatchMaster Manufacturing for SAP Business One

Harness the power of the best combo ever for recipe/formula-based manufacturers!

BatchMaster Software, an SAP certified partner, has seamlessly embedded its top-notch process manufacturing application into the SAP Business One framework. This complete solution caters to industries such as food, chemical, nutraceutical, and pharmaceutical. Offering functionalities like sample management, lab operations, formulation, production, costing, quality control, inventory management, compliance, planning, scheduling, and warehousing, it gives control over complete supply chain. With BatchMaster Manufacturing ERP for SAP Business One, users get real-time access to granular manufacturing data, through a single SAP login, granting a centralized access to a unified menu and database.

One Complete Solution

BatchMaster Manufacturing for SAP Business One is one complete solution designed to meet the emerging and ever-changing needs of formula and recipe-based manufacturers.

User-Friendly GUI

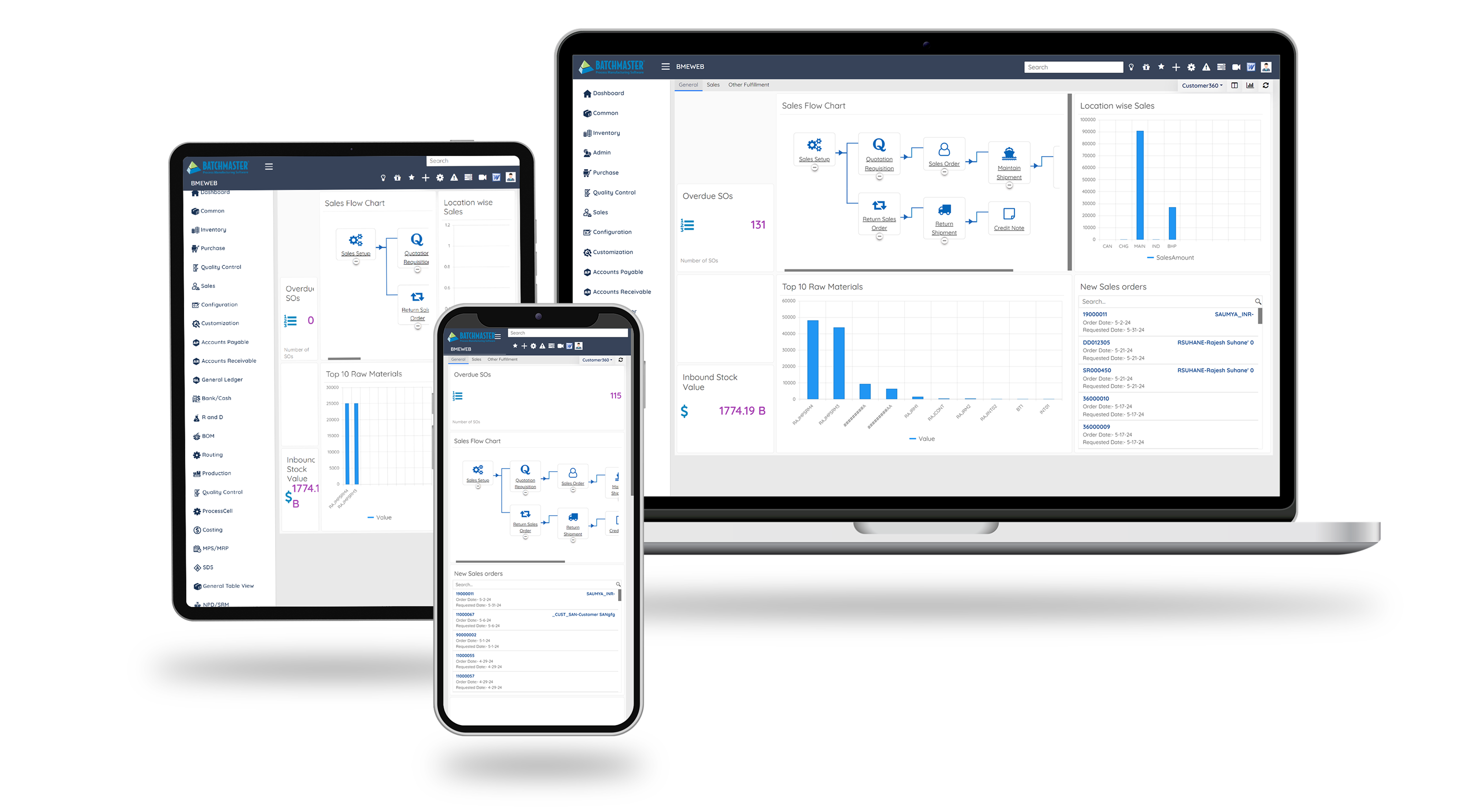

Offers the advantage of a single login, single database, and single interface. Familiar Business One look & feel as well as utilities, that along with Google-type search, relationship maps, alerts, and workflows make the working experience seamless.

Contemporary in its Approach

A team of researchers and experts keep a tab on the latest trends, technology, challenges, regulations, and industry best practices to ensure that these are addressed in the product.

Specially-Tailored For Your Industry

Designed to meet the real complexities faced by industries like Food & Beverages, Pharmaceutical, Paints & Coatings, Speciality Chemicals, Cosmetics & Personal Care and Foundry.

Adheres to Industry & Regulatory Compliance

BatchMaster Manufacturing for SAP Business One by-design helps you comply with customer, industry and federal regulatory requirements like, COA, FDA, GHS, FSSAI, FSMA, EPA and more.

BatchMaster SAP Business One ERP Add Ons

The performance of BatchMaster Manufacturing for SAP Business One can be further boosted with the help of exceptionally well-designed add-ons that cater to specific-est business needs with:

Allows remote execution of inventory transactions supported by the BatchMaster Manufacturing for SAP Business One from handheld devices, mobile, tabs, iPads and such.

Allows you to streamline your inventory management system, tracking and managing not just to the warehouse but to the bin level.

A comprehensive SAP Business One Add-On that helps Pharmaceutical/Nutraceutical manufacturers automate all the key business operations such as formulation, manufacturing, planning distribution, finance/accounting, inventory, and quality while helping them compliant with cGMP requirements effectively.

It is an SAP Business One Add-On that helps food/bakery manufacturers deal with the challenges related to manufacturing, distribution and finances, while also taking care of food safety & regulatory compliance, packaging and labeling, allergen warnings, shelf-life regulations, and inventory traceability.

Why BatchMaster Manufacturing for SAP Business One?

- Built on the strong foundation of SAP Business One

- Out-of-the-box fit with industry-specific solutions

- Supports complete supply chain

- Streamlined processes with reduced risks

- Helps adhere to regulations and best practices

- Real time information flow

- Innovate products faster and cheaper

- Faster yet accurate business decisions

- Aids in business analytics and market study

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find the Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs

About Us

BatchMaster Software is a global leader in enterprise solutions for process manufacturing industries, including food & beverage, pharmaceuticals, paints and coatings, chemicals, and cosmetics. With over 3,000 successful implementations worldwide and decades of expertise, we understand the unique challenges of these sectors. Our ERP solutions streamline industry-specific operations, manage critical processes across micro-verticals, and ensure compliance. Trusted by manufacturers globally to handle everything from production and distribution to finance, quality control, and regulatory requirements, BatchMaster operates from its headquarters in Irvine, California, with offices in India.