Material Requirements Planning (MRP)

Ensure that your commitments are met on time

What is Master Production Scheduling?

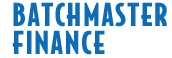

The Master Production Scheduling (MPS) functionality of BatchMaster ERP software’s MPS/MRP module assists manufacturers to compute and sustain an optimum manufacturing plan for what they need to produce, how much they need to produce, and when to produce, based upon sales forecast, planned purchase and production orders, inventory statuses, and work orders incorporating bill of materials to the lowest level. It provides the manufacturers with a detailed view of planned orders with drill down, analysis, grouping, and rescheduling capabilities, and allows them to create a relation between demand and supply and determine why and when batch jobs are required, through scheduling dashboards.

What is Material Requirement Planning Software?

The Material Requirement Planning (MRP) functionality, on the other hand, assists production managers in scheduling and placing orders for dependent demand items, and to maintain a flow of materials required for production by determining what to order, when to order, how much to order, and when to schedule the delivery of an order. The functions satisfy both demand-driven and batch scheduling methods.

MPS precedes the MRP function, focusing on planning on parts or the complete product of the whole production process, and subsequently creating the production orders. Whereas, MRP uses and processes data from BOM, Inventory and MPS to calculate the future requirements for materials. It pulls the data on demand from MPS, and accordingly performs material planning and creates purchase orders.

Features That Engineer A Paradigm Shift In The Way Process Manufacturers Work

- Provide more accurate capacity planning or time required as the production of a higher-level item is adjusted

- Use generic products and planning models to forecast and plan capacity at either product family or product level

- User-defined planning buckets allow you to establish up to short, medium and long-range planning horizons in days, weeks, months, years or any combination

- Packaging requirements and production job outputs are pegged to each order promise to allow instant visibility of customer specific requirements

- Evaluate and compare an unlimited number of alternative schedule versions and identify shortfalls

- Assess the impact of producing products using different specifications, plants or even process lines

- Establish short, medium and long-range planning periods

- Consolidate supply and demand of facilities

- Perform “what-if analysis” while planning production

- Perform demand to supply pegging as well as supply to demand pegging

- View time-phased aspects of required production, based on forecast and demand

- Schedule MPS processing on a frequency or calendar basis

- Auto conversion of MPS orders to purchase orders and batch production jobs

With BatchMaster Material Planning Module You Can:

- Effectively plan production and procurement activities

- Maintain optimum inventory levels

- Reduce inventory carrying and procurement costs

- Ensure production expected yields are met

- Increase customer service levels with timely deliveries

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

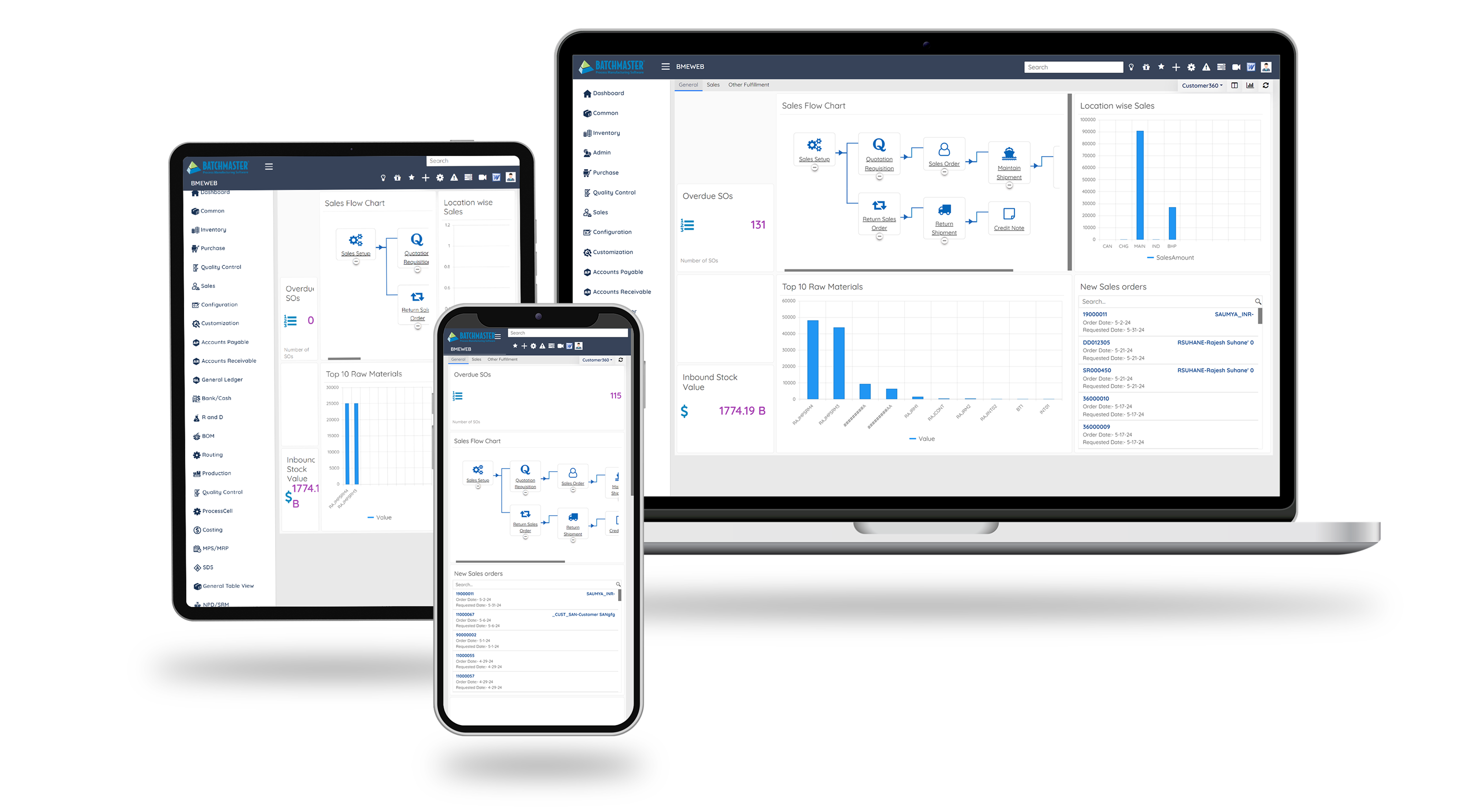

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs