Overview-

Overbaked biscuits,

Un-fluffy breads,

cakes lacking consistency,

or failing to implement enough quality checks!

Wait, hold on,

What about the changing consumer preferences?

and the shortage of skilled labour,

Seasonality affecting production calculations and the list goes on.

On one hand, bakery manufacturers have an ocean of opportunities to celebrate, due to the increasing number of consumers and their varied preferences. On the other hand, they are never short of challenges that this industry brings along.

Although the “taste” parameter holds prime importance in this industry, other visually appealing aspects, whether it be the fluffiness of puffs or the mouth-watering looks of desserts, are equally important to appeal to customers.

Imagine how challenging it must be for bakery manufacturers to maintain precise formulation accuracy while adhering to strict, industry-specific production standards for every single item. Even the slightest deviation in taste, color, or texture from the expected or traditional benchmarks can affect product quality — and risk disappointing loyal customers.

Now, add to that the daily pressure of managing these operations consistently, ensuring unwavering quality and flavor, and still keeping up with ever-changing market demand. It’s a daunting task that requires precision, control, and unwavering attention to detail; not possible through manual or spreadsheet based data management methods.

And that’s where the need for a robust bakery production ERP software gets highlighted.

But not all ERP systems are created equal. To truly serve the unique needs of a bakery business, your ERP software must come equipped with industry-specific features.

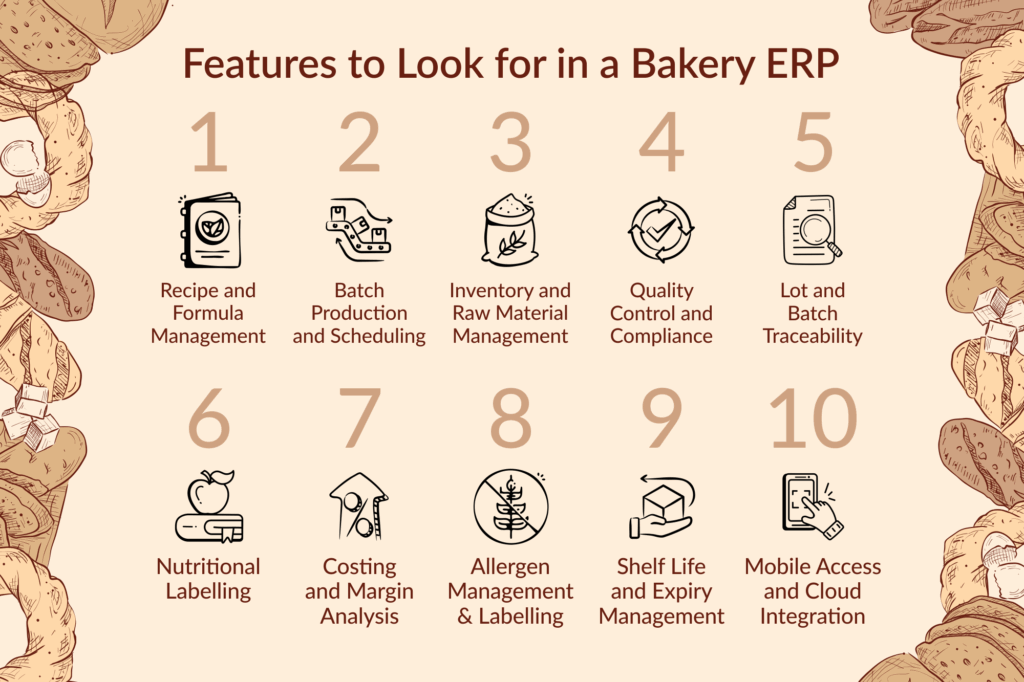

Here are the top features to look for in a Bakery Production ERP Software:

This study, which reveals the points to consider before choosing an ERP software, is a thoughtfully articulated outcome of the extensive research and the numerous surveys conducted by our team.

1. Recipe and Formula Management:

In a bakery, precision is non-negotiable. The ERP software’s formulation module should enable you to create, manage, and store thousands of recipes, along with their multiple versions to accommodate product variations and improvements.

Moreover, it must include features such as ingredient substitutions, allergen and nutritional data management, recipe recalculation to meet target properties, and multi-level recipe approval execution, among others.

2. Batch Production and Scheduling:

Efficient production planning is critical. Look for ERP systems that support batch-wise production planning, contract manufacturing environments, both make-to-stock and make-to-order operations, real-time scheduling, and capacity planning. This enables bakeries to optimise oven use, reduce downtime, and meet delivery deadlines without overproducing.

Moreover, it would be even better to have other supplementary features like the ability to adjust batch recipes dynamically, inventory in reserve for specific batch jobs, generating lot numbers automatically, etc.

3. Inventory and Raw Material Management:

Bakery ingredients are often perishable and expensive. ERP software should provide exceptional inventory management capabilities like real-time inventory tracking via FIFO (First-In, First-Out) or FEFO (First-Expired, First-Out) methods, and automated alerts for low stock levels, to ensure uninterrupted and safe production.

Moreover, it must facilitate:

- Performing warehouse management functions including receiving, put-away, picking, shipping, physical counts, and transfers seamlessly.

- Tracking inventory by item, warehouse, lot, status, location, attributes and license.

4. Quality Control and Compliance:

Consistency and food safety are paramount in food manufacturing. Your ERP must allow you to establish and enforce quality checks at every critical stage—right from raw material inspection, through in-process control, to finished goods testing.

The chosen ERP should even provide:

- Preconfigured libraries of vendor inspection plans and checklists tailored for raw materials, WIP (work-in-progress), finished goods, and even equipment.

- Equipment-specific checklists to monitor continuous flow operations and maintain production consistency.

- Customisable COA (Certificate of Analysis) reports to accompany outgoing shipments.

- Integrated USDA and Genesis databases to determine ingredient physical and nutritional characteristics.

5. Lot and Batch Traceability:

In the event of a recall, being able to trace ingredients and finished goods by lot or batch is essential. A good ERP system provides end-to-end bi-directional traceability, helping you track products from raw material to customer delivery, and the other way around.

Adding more to this, your chosen bakery production ERP should be capable of maintaining detailed records of each lot, including source, purchase details, vendor lot number, vendor certifications (if any), quantity received, current stock levels, and associated purchase orders.

6. Nutritional Labelling:

The labelling capabilities of Bakery ERP software ensure accurate, compliant, and automated label generation for every product. It allows bakeries to include key details like ingredients, nutritional information, allergens, batch numbers, and expiry dates.

Labels can be customized to meet regulatory requirements and brand standards, improving traceability and consumer trust. Integrated printing support ensures efficiency and consistency across all packaging lines.

7. Costing and Margin Analysis:

Bakeries operate on tight margins. An ERP system should provide accurate cost breakdowns for each product, factoring in ingredient costs, labour, packaging, and overheads. Moreover, it should even provide real-time profitability insights to enable better pricing and operational decisions.

8. Allergen Management & Labelling:

Consumer demand for transparency is on the rise. ERP software should support allergen handling, segregation, tracking and automatic generation of Allergen labels based on recipes. This feature is crucial for packaging, e-commerce listings, and customer trust.

9. Shelf Life and Expiry Management:

With short shelf lives being a major concern in bakery products, ERP systems must manage expiry dates, track best-before timelines, and provide alerts to prevent product spoilage and loss. By tracking the expiry dates, the ERP software automatically prevents the expired item from being sold or issued in production.

10. Mobile Access and Cloud Integration:

Modern bakeries need access to data anytime, anywhere. Cloud-based ERP solutions with mobile access allow real-time monitoring of production, inventory, and sales, even when you’re on the shop floor or away from the bakery.

What else is needed is that the chosen ERP should be capable of-

- Dynamically sizing & scheduling batch jobs in batch and continuous flow production modes.

- Planning production based on the equipment rates and capacity, e.g. mixers, dividers, ovens, wrappers, etc.

- Forecasting batch production jobs and purchase orders based on supply and demand.

- Prioritizing the scheduling & execution of specific batch jobs.

Final Words-

The bakery business is both an art and a science, where creativity meets precision, and quality must never be compromised.

As bakery manufacturers juggle diverse challenges, including fluctuating demand, seasonal production changes, quality control, and rising consumer expectations, a generic ERP system simply won’t suffice.

To thrive in this competitive market, what bakery manufacturers need is an industry-specific Bakery Production ERP that properly understands the nuances of this industry, from recipes to production specifications, and everything. Adopt BatchMaster ERP software for bakery production that meets the bakery business needs properly while streamlining all their operations.