An effective supply chain management determines success of an organisation. But how can organisations achieve better SCM?

How can they benefit from new technologies available? Know everything about an effective Supply Chain Management in the blog.

Supply chain management is managing, organising, and deploying raw materials, machines, people, and other resources to get optimum output.

It comprises execution, operation, and supervision of many areas like procurement, purchasing, production, distribution, strategy, and sustainability.

With proper supply chain management, organisations can speed up production, raise quality standard, save time and cost.

In this blog we will talk everything about supply chain management and will find out how organisations can improve their supply chain management to increase profits.

So, without further ado, lets dive into the subject.

In this blog:

- Supply chain Vs Supply Chain Management

- Concept of Supply Chain Management

- Components of Supply Chain Management

- Why Supply Chain Management is important

- Benefits of Supply Chain Management

- Final Thoughts

Supply Chain Vs Supply Chain Management –

Are you in doubt about supply chain and supply chain management? Let me clarify!

Supply chain is movement of raw material from supplier to warehouse, to production to finished good and to the customers.

To ensure that the movement becomes smooth and flawless, SCM is necessary.

Hence, we can say that SCM is the management technique or invigilation interference by human or machine to ensure that the material in every stage of supply chain move in lucid way, both forward and backward.

Now, as you know the difference, let us understand about the concept of SCM.

Concept of Supply Chain Management –

As discussed above, the concept of Supply Chain Management originates from the wilful invigilation of each touch point in supply chain.

Therefore, it is ensuring quality and in-time procurement of raw materials from the suppliers, storing in well managed warehouse with favourable conditions, assigning it to the right machine for correct production and producing the product.

This further exceeds to delivery and feedback from the customers.

In today’s world, consumers and compliance demand a deeper view into every aspect of the product.

Thus, SCM also incorporates transparency in best practices, like from where raw material is sourced, what labour conditions involved in production, carbon footprint of operation, etc.

Components of Supply Chain Management –

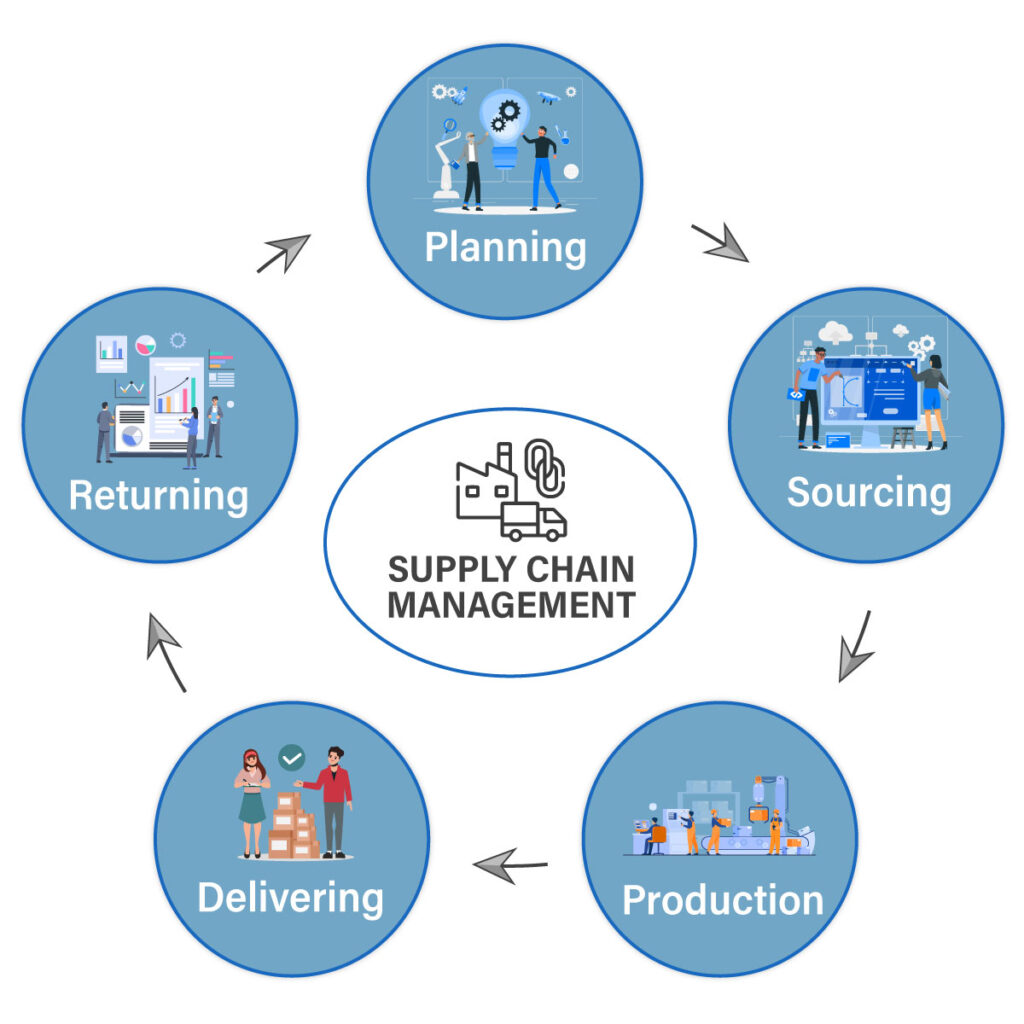

Supply chain management is a long process. We can divide this into the following components:

Planning –

Planning in any activity is important. Planning in supply chain tries to coordinate among supply chain partners like suppliers, manufacturers, distributors, and retailers to balance supply and demand.

It involves establishing synergy among men, machine, technology, material, and organisational capabilities.

With BatchMaster ERP, organisations can plan precisely. MPS/MRP module help manufacturers to plan.

MPS part of the ERP helps organisation to plan:

- What to produce

- How much to produce

- When to produce

This planning is based upon sales forecast, planned purchase, and production orders.

It allows manufacturer to reschedule, and group production.

MRP helps organisations to:

- Schedule and place orders for depended demand

- Maintain material flow for production

- Determine order time

- Determine order quantity

- Schedule delivery of an order

Sourcing –

While finalizing a supplier, only cost is not the factor to consider. There are quite a more factors like quality of material, lead time (the time in which supplier can supply) etc which are equally important.

Poor quality product at cheaper rates will do more harm to your brand than no product. Thus, a supplier should be selected by keeping in view all factors.

BatchMaster ERP helps you to select a supplier basis various parameter, like delivery, quality, lead time and pricing.

It can save vendor certificates, vendor contracts, landed cost, vendor item’s price, discounts etc.

BatchMaster ERP can enable organisations to purchase from a verified supplier.

Production-

A manufacturing company exists to produce! Thus, production is a crucial, although not the final, aspect of SCM.

Manufacturing process may be further divided into sub-tasks like assembly, testing, inspection, or packaging.

During the whole production, an organisation endeavours to use resources to the fullest, and minimize wastage.

BatchMaster ERP helps organisation to optimize productions by:

- Supporting batch creation, ticket, issue, and closure

- Anytime batch sizing (according to available material, order, finished goods target etc)

- Providing make-to-stock and make-to-order manufacturing ability

- Allowing full or partial closing of batch for urgent shipment

- Creation of batches with Allergen, Kosher, or Halal ingredient

- Supporting rework of excess product into WIP, and WIP resale

- Identifying critical material

Delivering –

After the product has been produced and sales deal has been finalized, now it’s time to deliver it to the customer.

The speed and quality at which an organisation delivers the product to the customer determine the loyalty of the customer towards the brand.

This is an important part of SCM, as organisation must find out logistics partners who can deliver the product with minimum time and delivery cost.

Alongside, organisation must have backups of delivery channels in case one channel is temporarily disrupted.

The process of delivery starts with picking, packing and then shipping.

BatchMaster ERP facilitates these processes by:

- Enabling you to generate picklist, pack slip and GRN

- Applying quality test to the product before finally shipping

- Printing bill of lading

- Allowing POD and order acknowledgement printing

- Allowing multiple shipment to fasten shipping process

- Generating packing document for all goods shipped to a customer

- Generating a delivery tracking number

Returning-

Although returns are bad for an organisation, but sometimes it happens.

Situation is worse when the return is an effect of non-conformance or quality issue at manufacturer’s end.

The company should ensure that it has equally robust reverse logistics management to handle returns and process refunds.

Distribution network management system of BatchMaster ERP is well equipped to tackle the situation.

It can:

- Automate RMA (Return Material Authorization) process,

- involving timely return of product,

- and transferring it back to the inventory/scrapping as the case be.

Why Supply Chain Management is Important?

SCM is necessary to achieve various objectives. It can control product quality and mitigate risk of recalls.

Overall better SCM provides organisations many avenues to enhance growth and book more profit by utilizing resources more judicially.

With the help of BatchMaster ERP, organisations can apply quality checks, find non-conformance, and mitigate chances of lot recalls.

Benefits of Supply Chain Management –

Supply Chain Management is complex but vital. It involves simultaneous management at many touchpoints of supply chain which is not possible manually.

Hence a supply chain management software or a supply chain management system, just like BatchMaster ERP, must take charge to simply it.

Once done properly, supply chain management can offer numerous benefits like:

Better collaboration –

In a complex supply chain scenario, organisations don’t get real-time view of end-to-end supply chain, resulting opportunity losses.

SCM system improves the visibility at every point, making supply managers to take critical decisions easily.

Reduced cost–

Business can inspect their current processes, identify flaws, and rectify them.

Eventually this rectification can lessen cost. Thus, companies can produce more product in less money.

Customer satisfaction –

An effective supply chain management helps business to build a good market reputation.

It improves ability of organisations to respond fast to the market demands, and hence improve brand image and loyalty.

This attracts more customers as well. Therefore, to ensure a smooth flow of goods or service, businesses must invest in an effective supply chain management system like BatchMaster ERP.

Besides other advantages, it provides cloud-based supply chain management solution also, ensuring anywhere, anytime control over business.

Better risk management –

With properly managed supply chain, businesses can analyse both big picture and granular supply chain and devise a strategy to counter probable risk.

This way, companies can take proactive decisions rather than being a trap of turbulence like supply chain disruption, or quality issue.

Consistent quality –

With quality issues, the cost of doing business rises.

A well manged supply chain ensures quality check at every step of supply chain, maintaining quality of the product. ERP software like BatchMaster with its-

ensures that only quality passed goods flow through the supply chain, resulting a quality consistent product.

Controlled inventory management –

A well-managed supply chain can reduce waste. It can stop overstocking and avert understocking.

ERP software like BatchMaster help organisations to control inventory effectively by:

- Tracking inventory based on bin location ID, serial or lot number, LIFO, FIFO or FEFO, ABC analysis

- Running inventory counts

- Setting up EOQ (Economic Order Quantity), safety stock and ROP

- Managing expiries and shelf life

- Classifying inventory, setting attributes and potency, and managing them at pallets, bins, lots and serial levels

- Scanning inventory items via handheld devices

- Performing Physical and Cycle Count

Shipping optimization –

Shipping cost and identifying shipping partners have been a vital facets of supply chain management.

Identifying economic shipping partner for large boxes, small parcels, bulk orders etc can reduce overall cost of the product.

Final thoughts –

The stability of a manufacturing organisation depends greatly upon the quality of supply chain management.

In the complex business world like today, where supply chain has many threats like war threats, new virus attacks, changing geo-political scenarios, fuel crisis, economic slowdown, organisations need a robust shield to effectively manage their supply chain.

One such robust shield is BatchMaster ERP. To know about BatchMaster ERP, please contact.