Overview-

Being in the Marketing & Pre-Sales department of a Software Development company, I am, from not so long ago, witnessing a steep rise in the ERP inquiries.

Probably because, more and more manufacturers are realizing that automation is the key to survival and success today.

To shine through in this unpredictable and ever-changing market conditions, they need to look beyond their traditional methods of working.

And, an ERP can help them get control of their business and look at it as one entity.

It will also help them find the imperfections in their business processes, monitor the external and internal problems and take the right decisions to get success in every attempt.

Of all the questions coming in, the most frequently asked is- “Which modules are essential from a process manufacturing viewpoint?” So, I thought to write my answer for all the process manufacturers out there looking for an ERP.

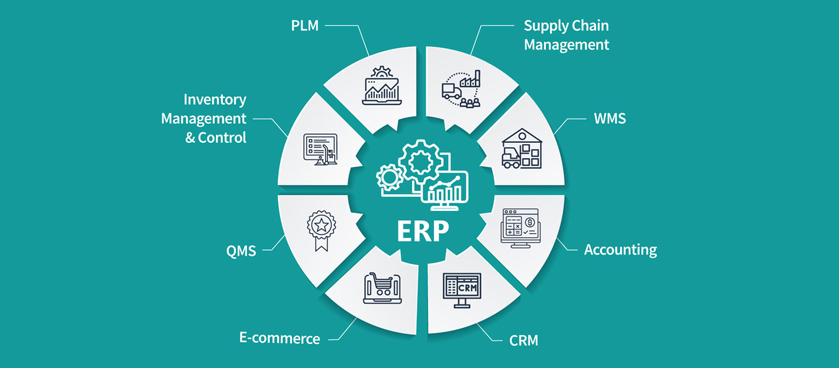

Here’s the list of modules of an ERP that I think are necessary for a manufacturing company:

10. Inventory Management meets your unique business needs

The Inventory module provides powerful and flexible features to help you manage and handle your inventory more efficiently.

These features help in maintaining optimum inventory levels while eliminating the situation of overstock or understock.

ERP supports the tracking of production quality, expiry date, shelf-life period, and lot-controlled products. You can gain real time visibility of inventory in stock for performing any inventory transaction.

Additionally, it makes your inventory levels ideal and accurate by tracking the inventory present in multiple warehouses.

The tracking can be done bin wise, item wise, warehouse wise, lot wise or container wise, along with setting up various storage conditions for bins and items.

You can get an instant update of the current inventory valuation based on the costing method your company follows.

With ERP’s inventory management by your side there is tighter control of inventory and reduced wastage.

9. The unmatched Quality Control experience

The Quality Control module allows to put different quality checks at every point wherever required. This guarantees that the expected quality is achieved for every product.

Moreover, for better quality assurance, ERP provides the facility of double sampling by characterizing the tests to associating it with items during sales, purchase, and production.

The accurate quality-focused tools of ERP help achieve optimal quality control for every phase of your operations.

From receiving raw materials, through production of intermediates/finished goods, to inspections of finished goods before dispatching.

The fully integrated quality control manages the record of pass/fail statistics depending upon user defined specifications that can be one or many.

This helps you to accept or reject the product based on inspection results.

Also, immediate action, like destruction, return etc. can be taken against the items that fail QC Inspection.

Thus, quality checks at every step ensured by an ERP solution helps to deliver safe and compliant products throughout.

8. Win the strictest Regulatory Compliance

Delivering safe, uniform quality products that meet strict regulatory standards is the necessity of today’s competitive market.

With the help of ERP, you can monitor and record real time manufacturing activities, in accordance with cGMP norms.

Moreover, it also helps in tracking nonconformance and performing CAPA for rejected materials.

Some ERPs are even capable of automatically generating Material Safety Data Sheets that are in full compliance with governmental regulations.

They offer complete freedom to decide and manage multiple MSDS formats along with the facility of custom-made templates.

They are even capable of customization to meet new regulatory issues without incorporating major changes.

This helps you keep the recalls, daunting audits, and fear of negative brand reputation at bay.

7. Display Strategic Growth with Managed Finance Processes

ERP removes all your financial worries and handles financial operations smoothly.

The all-inclusive Finance module takes productivity to new levels, while ensuring greater transparency and more liquid cash.

ERP excels in completely satisfying statutory requirements in-line with current governmental regulations.

This is done by arranging data of every transaction of sales, purchase, production, warehouse transfers, etc. with finance.

The strength of ERP lies in its ability to handle financial operations accurately, which are reliable and truly cost-effective.

It eliminates unnecessary entries and allows end-to-end, precise yet faster financial accounting.

Moreover, many ERPs allow multi-lingual and multi-currency support along with offering numerous accounting methods.

This results in smoother and faster journal entries, bank reconciliations, transaction posting, etc.

These incredible capabilities ensure complete, in-depth plus real-time visibility into business performance and increased profit.

6. Ensure Continuity with MPS & MRP

With the help of an ERP, manufacturers can carry out customer requirements without experiencing imbalance between the demand and supply.

This is because, the Master Production Scheduling (MPS) focuses on planning of your job orders considering the demand and availability.

Whereas MRP suggests what to be procured and when to be procured.

The MPS functionality also helps in:

- Designing the material requirement plan

- Production of components

- Prioritizing of the orders, and

- Short-term capacity requirements.

ERP integrates MPS and MRP to determine orders and allows last minute rescheduling and efficient allocation of resources.

Correspondingly, MRP allows to confidently sustain with the lowest possible material and product level in stock and automatically generates purchase orders from net demand relative to reorder threshold levels.

ERP promotes easy view of production bottlenecks through an interactive graphical interface, giving you the complete picture with finer detail.

5. Simplify your Purchase

When planning is efficiently handled by MPS, purchase becomes easy to execute.

Making the procurement efficient and quick from ordering to receipt and invoicing, ERP’s Purchase Module helps you through it all. It ensures material availability and increase planning stability.

The Procurement module of ERP efficiently evaluates the best vendor based on one or more criteria like delivery, quality, lead time and pricing.

It also supports Vendor Contracts, Landed Costs, Direct Delivery orders, Return as well as Rejected Return Orders.

4. Target Profitable opportunities with efficient Sales

The Sales module provides control over sales related operations. It is a single unified solution to manage all operations related to sales.

This includes returns and processing of sales orders, from order entry to printing and posting work orders.

It keeps a track of order fulfilment from quotation entry to invoice creation.

With the aim to have a superior customer service and simpler Order–to-cash cycle, ERP encourages faster order creation, instant picking, packing and shipment, contract definition, pricing and discounts that too customer and customer-class wise.

The system automatically categorizes customers as active/inactive/hold, and applies discounts & taxes based on customer details in the database.

Then separates customer classes or groups and fetches right price, bulk pricing, discounts and offers at the time of billing.

ERP makes a note of the credit limit for each customer and restricts from dispatching if the credit limit exceeds. By managing your complete sales cycle, it increases responsiveness, timely deliveries and thus ensures a more satisfied customer base.

3. Be Obedient with GST

The new financial year has bought GST along with it in the form of the latest development in the tax laws.

Because of this, manufacturers are constantly trying to get GST compliant IT/ERP solutions.

Adding to it are the requirements of e-Signature, keeping atrial of transactions, generating E-Way Bill and such.

Although, GST might simplify the taxing complexities to a great extent, but its proper implementation and execution would be essential.

Hence it has become one of the most popular modules of the ERP for process manufacturers.

2. Run Production process like never before

Process manufacturing is complex in nature as it involves mixing, grinding, heating, state change, filling, assembling, and more.

But ERP is known for simplifying these complexities and increasing workflow efficiency.

It provides powerful set of features that guarantee accurate processing of production activities, from start to finish.

Irrespective of the type of process, from mixing, filling or assembling of materials, it allows creating batches for all types quickly.

It supports, manages, tracks and controls all the production activities from batch creation, allocation, inspection, quality checking, to finally closing it.

Tracking costs along the process of material, labour, machinery, and losses involved, it even considers the concept of WIPs.

It can accommodate your last-minute configuration changes, or change in customer requirement, unavailability of material, etc., through its automatic batch sizing and material substitution.

- Several reports and dashboards help-

- Instantly applying changes in schedule,

- know how much and what is in production,

- if all SOPs are followed,

- are there any deviations,

- what corrective actions should be taken,

and much more to simplify and smoothen your production process.

1. Bring new products faster & cheaper with Product Development

Bringing innovative products in the market quickly is what is expected by today’s customers. And an ERP’s Formula and R&D modules make it possible for any process manufacturer.

With the help of Formula module, the recipe created can be managed, approved, secured, revised, and archived electronically for future reusing.

Thus, it saves immense time that goes into re-formulating from scratch. Moreover, material substitution can be executed easily to accommodate changes in the original formula.

Whereas R&D module of an ERP gives power of accurate calculation to achieve the targeted physical, nutritional or specific characteristic, and specific packaging based on the nature of product.

Samples management can be carried out based on specific customer requirement.

Also, the sampling history can be tracked, costs calculated and can be shared with the customer for approval.

The quotations can then be created right there, and entry of new materials used/created can be made directly, accelerating the entire process.

Conclusion-

These 10 modules are essential for a manufacturing company to face the challenges of the current dynamic market.

Tasks like innovating continuously, meeting compliance, securing profit margins, reducing waste, or improving logistics, such tasks require specific functionalities.

That’s why this list of ERP software modules will help you sail smoothly and efficiently on the path to success.