Food manufacturers, particularly the ones that work in the meat, seafood, or poultry sectors, are well aware of the term “catch weight”, the challenges that it presents, and the importance of managing it.

For the uninitiated ones, this blog touches upon the concept of catch weight, and gives out all the related information in detail.

Table of Contents:

- Overview

- This brings us to catch weight management

- Catch weight, defined

- Importance of catch weight management in meat industry

- The role an ERP software for meat industry plays for meat producers

- Conclusion

Overview

An enterprise resource planning (ERP) software is an absolute necessity for food manufacturers. It is a fact that has been established beyond any reasonable doubt.

For an industry with challenges such as razor-thin margins, stringent regulations, and demanding customers, among others, an ERP software is certainly mandatory.

The food industry is vastly diverse, and has different sub-sectors such as bakery, fish & seafood, meat, poultry, dairy, packaged food, and many more. Each of this sectors is unique with respect to its needs and challenges.

However, amid all the differences and diversities, these manufacturing businesses are united by one common factor- the ERP solution.

An ERP system tailored to the needs of a specific vertical within the food industry can help meet the key requirements of manufacturing and distribution operations, improve the process efficiencies, reduce costs, waste, & risks, and ensure compliance with the regulations.

Moreover, it can help food manufacturers in any specific area of their business.

This brings us to catch weight management

We talked about the food manufacturing industry being diverse and its micro-verticals being unique, having specific requirements and different processes than others.

This means that while their primary needs such as managing inventory, production, warehouse operations, accounting, procurement, and sales, etc., remain the same, there are certain specific needs too.

Just to quote a few examples, concepts such as variable catch weight products, shelf life of the products, and inconsistent raw materials separate the food industry from others.

While some of the other industries enjoy the consistency of raw materials, with a piece being a piece, few sectors from the food industry, namely meat and seafood, require catch weight management.

Catch weight, also known as variable weight, signifies the “approximate weight” of a product.

A good understanding of catch weight management, and the ability to get it right, helps food industry operators such as meat producers/processors hold their ground in competition, open up new avenues of sales, keep their profits high, and the customers satisfied.

Catch weight, defined

Catch weight can be defined as the actual weight of an individual food item that is sent to the buyer, and is usually applicable in the case of pricing the products with variable weights; particularly the ones that vary in sizes, for example, products like meats, steaks, and seafood, blocks of cheese, fruits, and vegetables, etc.

These units are typically sold in bulk, and invariably priced by their weight, instead of the discrete units of measure. Chicken breasts are a good example.

Its single unit, which is often sold in a package of four, never costs the same, because each package is irregular in size and has different weights.

This means two packages having four pieces each could contain different amount of chicken by weight. Now, selling them at a uniform price could mean that one customer gets 22 ounces of chicken, another gets 24, while the other gets 26 ounces, all for the same price.

Thus, the prices of those packages must reflect that difference, and that’s why the packages are priced by weight.

Trivia

The concept of catch weight derives its name from the sports of boxing and wrestling, where it was instituted to weigh the two participants before a bout to ensure that they are within the range of the weight class for the event, and none of them holds an unfair weight advantage over the other. This way, catch weight helps keep the playing field level.

Importance of catch weight management in meat industry

Catch weight management holds particular significance in the meat industry. It has direct implications for a meat producer in terms of time, money, and customer satisfaction.

Meat producers involved in the business of selling cuts of meats are required to manage products with weight variability. The cost of these kind of products changes according to the weight.

We discussed above how no two packages of chicken breast will have the same weight, even if they carry the same number of items.

So, the meat producers here need to know the average weight of the food they manufacture, produce, or store. In this case, they must know the average weight of a chicken breast.

That will help them when they make estimates about their supply.

But when they price their products based on average weight, the problem begins. In that case, the items either weigh significantly under, or over the average weight.

If the item is underweight, the customers/businesses that are the buyers feel cheated. Meat producers spend considerable time dealing with their complaints, and run risk of losing their business.

On the other hand, when the item sold is consistently overweight for a long period, the expenses get added up over time, and result in huge losses for the seller.

This is why catch weight becomes important for products with variable weights. In either case, catch weight management helps the meat producers avoid costly errors, and keeps them in good stead.

The role an ERP software for meat industry plays for meat producers

It is clear that catch weight management is important for meat industry. However, it is effective only when done right. If done manually, it can be extremely labor-intensive, costly, and error prone.

Meat producers who opt for manual way of doing it end up investing huge amount of cost and time into tracking each weight.

But an ERP for meat industry automates and simplifies the task of accurately tracking and reporting inventory and sales of products that can vary in size, and in the process, helps meat producers save their money and time.

It ensures that the units are properly labeled, and their weights are properly recorded as they come off the line.

A catch weight management ERP makes use of two units of measurement- the inventory unit, which refers to the unit by which the item is weighed and stored, and the catch weight unit, which refers to the unit in which the product is sold, and shipped.

This makes it possible for the meat producers to capture the exact weights, price the items by their weight, and sell them according to a physical unit.

In the presence of an ERP, the meat producers simply deliver accurate inventory cost and customer pricing, without those time-taking, laborious and error-prone calculations. Moreover, it even allows defining the Catch-Weight range; subsequently, when the system encounters products falling off the range, it prompts user with a message.

Among other things, a meat ERP software allows recording and maintaining catch weights for individual lot and license plate records at all steps along the supply chain, eliminating human errors, offering real-time inventory and sales tracking, maintaining data with tolerances, and prompting alerts when catch weight goes beyond range, and providing the meat producers with the capabilities like catch weight processing, tracing, and real-time yield management.

Conclusion

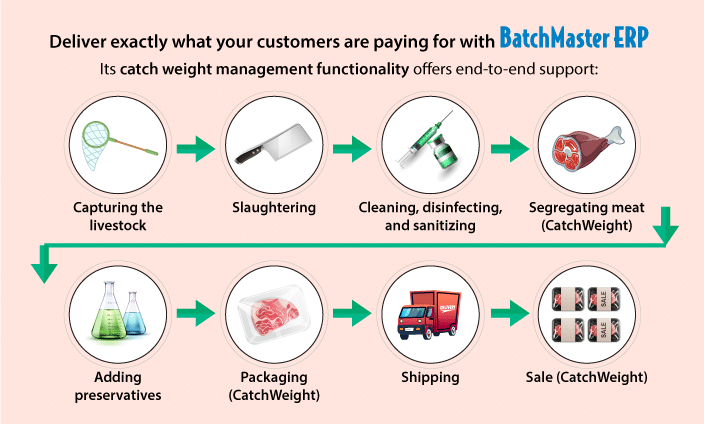

Having a meat processing ERP software with catch weight management functionality is a must for meat producers and processors, so that they can deliver exactly what their customers are paying for.

At BatchMaster, we have a rich experience of serving different verticals of the food manufacturing industry, including meat, poultry, and seafood, among many others.

Our meat ERP software- BatchMaster ERP, not only comes with the catch weight management feature, but also with a host of other functionalities that are designed with industry best practices in mind.

Ready to learn more about our effective catch weight management solution? Get in touch by writing to us, today.