If we talk about the food manufacturing industry, there’s a special emphasis on ensuring the quality and safety of the end products.

The reason is simple, because any slight deviation, or any inconsistency in the quality standards can lead to manufacturing of products that are not fit for consumption, which may in turn have disastrous effects on the end consumer’s health.

The number of foodborne diseases that have emerged in recent years, and higher risk of contamination due to long, and complex supply chains, have only worsened the things for the food manufacturers, who now feel the need to address the public health concerns on top priority, more than ever.

It is not for nothing, after all, that the food manufacturing industry witnesses such strict regulations being put in place by the government organizations like the FDA, and other regulators.

But in their bid to meet these stringent regulations and ensuring food safety and quality control, the food manufacturers face certain challenges.

To achieve traceability, they either rely on old-school methods of doing things manually on paper, or through spreadsheets or multiple disparate systems.

But these methods are ineffective, as the absence of a specialized tool such as a food traceability software means that they struggle to improve traceability in supply chain, quickly recall products in the event of non-conformance, and track production, among other things.

It is especially important to have a food traceability system because problems can occur at any point along the supply chain – from R&D through materials handling to assembly to shipping.

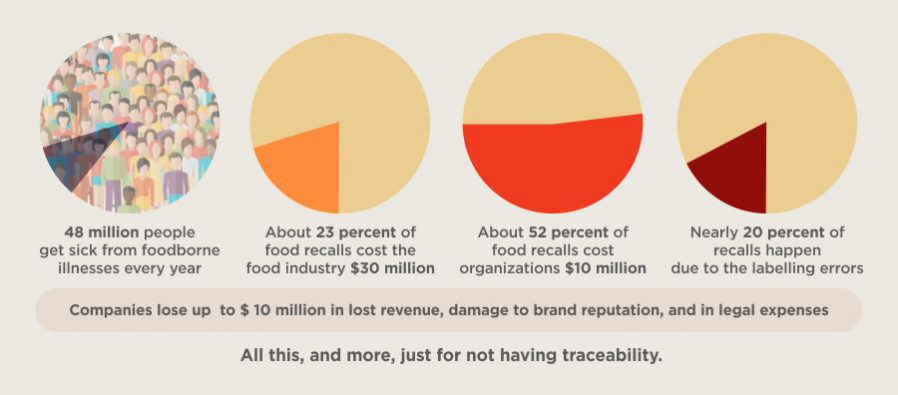

And when they do occur, not having the traceability can have devastating consequences for the manufacturers.

Hence, traceability of food products back from the consumer to the very beginning of the supply chain is very important.

And to have this ability, a traceability software for manufacturing is a must

Let’s understand the importance of food manufacturing traceability software for food safety & quality control in a detailed way by going in a reverse manner.

Let’s see how the life of a food manufacturer would be in the absence of a food traceability software.

Use a software or don’t, the ultimate objective of the food manufacturers never changes- they need to deliver high-quality and safe products every single time.

The stakes are pretty high, especially with the modern consumers having access to details about virtually every minute aspect of the products they consume, like where they come from, how they are made, what they are made up of, etc.

What this has essentially done for the manufacturers is that now they feel greater pressure to maintain supply chain transparency, and to meet the stringent regulatory & safety requirements.

But since they don’t have a traceability software for food manufacturing at their disposal, they resort to the manual methods, and the use of electronic spreadsheets, which are never effective in the long run.

Having disparate systems doesn’t work

The other approach most food manufacturers adopt is of having disparate systems, i.e. having multiple software to manage different functions.

They deploy one system for assessing risks, another for ordering, and perhaps another for managing inventory.

But with all these systems and different spread sheets as well as databases, the manufacturing organizations find it difficult to get hold of the right information in a quick time.

Furthermore, the presence of disparate systems also forces the staff to spend substantial time of their day juggling between applications to perform different tasks.

As a result, the manufacturing organizations actually end up going nowhere, and gradually grind to a halt. Their brand value takes a beating in the absence of traceable data available to them, as they fail to curb the consequences of a product recall.

The organizations lose exorbitant money in lost revenue, damage to brand reputation, legal expenses, as well as the ability to make new money – all this just for not having the traceability software.

That’s why food manufacturers need a food traceability software

The only way food manufacturing businesses can escape the situation mentioned above, is by achieving end-to-end traceability, i.e. the ability to track the movement of various food products, raw materials, additives, other ingredients and packaging throughout the different stages of production, processing and distribution by recording and proper documentation.

And the only way they can achieve end-to-end traceability, is by having one integrated traceability software for manufacturing.

By having such software, locating any product anywhere in the food chain becomes an easy job, as its scope covers the origin of every single material and its processing history. This is what it essentially does:

- A food traceability software provides the food manufacturers with the required visibility into food safety, quality control and traceability, by allowing them to effectively automate and integrate traceability across their supply chains.

- It records and manages the data from every point in the supply chain, thus providing an audit trail and allowing the manufacturers to track their products and the ingredients both upstream and downstream.

- This way, it enables the manufacturers to trace and track- i.e. move backward to the point of origin, and make forward movement to the destination, lets them know exactly where the non-conformity happened in the supply chain, and allows them to access information about the grower, supplier, etc. associated with the affected lots.

- Having this information at their disposal, the food manufacturers can specifically recall only the affected product lots, and avoid any other damages.

- And hence, they can command greater trust and confidence from all the stakeholders- namely the retailers, consumers, auditors, regulators, and inspectors. This trust eventually translates into higher market share among distribution channels and consumers, and greater profitability.

- The manufacturers can enjoy more benefits of traceability such as improved operational efficiency, assured quality, better brand credibility, and lower risk of legal issues, timely error prevention, faster recalls, minimized downtime, and enhanced inventory visibility, among others.

What’s more, a traceability software for manufacturing saves time, money, and other resources, and ensures quality by eliminating error-prone manual processes of recording the lot numbers of the products and entering them into spreadsheets. It also helps meet all the local, regional, national, and international regulatory requirements, prevent unfair trade practices, and record maintenance.

To sum up

To ensure food safety and quality control, the key for the food manufacturing businesses is to look for a food traceability software that not just fits into their specific business needs seamlessly, but also accurately traces the data throughout the entire flow of production, drill down into records and batch sequences for auditing and transaction history, and eventually helps them deal with the challenges that can arise on the shop floor, and beyond it.

BatchMaster has transformed food businesses through its range of industry-specific as well as micro-verticalized ERP software for over 30 years now.

With its different ERP offerings, it can help you achieve traceability, and ensure safety and quality of your products.

For more information on our different food & beverages industry-specific software or reach out to us at sales@batchmaster.com.