Overview-

We don’t give a second thought about where our things come from. We usually buy and use them, rarely thinking about how & where they are made.

We even don’t consider the fact that hours and hours of effort are put into making everything that we use.

It’s a matter to think that when there was no technological development in manufacturing, how items were manufactured. Those manual production processes used to take several days to complete.

Right from maintaining inventory to planning and executing the production, everything was man powered.

Things started to change after the industrial revolution. Incorporating automated processes became the worldwide trend—eliminating the old-fashioned labor intended procedures.

The next major step, taken by the manufacturing industry was the development of technological tools, first MRP, later upgraded as an ERP.

These two software systems were developed with the intention of automating supply chain processes

The adoption of these techniques started benefiting companies by offering a dramatic reduction in their material costs and production time.

This combination of technology—linking every manufacturing operation with technology, created a stepping stone for the manufacturers to achieve success.

Though these resources, MRP and ERP, optimize manufacturing units proactively but differs from each other on multiple fronts.

Understanding the Concept of MRP Systems-

The term “MRP” stands for material requirements planning software in the manufacturing industry.

The basic objective of this solution is to determine and measure how much and when the production materials are required. This makes it possible for manufacturers to prevent downtime-related productivity loss.

This manufacturing-centric software allows companies to better monitor their inventory and plan their production.

This implies that the program may be used to quickly identify the materials needed to produce the required out when an order is placed.

Moreover, MRP systems are useful for production planning even in organizations whose major roles are not in manufacturing.

In such cases, the production schedulers can estimate demand, order the right supplies, and maintain the right amounts of inventory with the use of this program.

Prominent Objectives of MRP System-

This system keeps manufacturers ready for the competition by working upon its below-mentioned objectives-

- Ensuring the availability of the necessary resources for production

- Ensuring that finished goods are accessible for delivery to clients

- Optimizing inventory levels by maintaining materials and final products

- Organizing production processes such as sales orders, and purchasing

Evolution of MRP to MRP II & Its Limitations-

Gradually with time, the market trends evolved due to the changing needs of the consumers. This sparked a global competition between the companies twisting manufacturers’ arms to provide more customized products according to their needs.

Hence, these new products require a progressive approach to manufacturing to efficiently manage the increasing product complexities.

For this, the MRP II was invented.

This advanced version of MRP I was programmed to provide additional functionalities like finances, general accounting, machine, and labor capacity planning, quality assurance, etc. to the organizations for delivering better results.

Beyond material requirements, the idea of Manufacturing Resource Planning (MRP II) was to serve the entire manufacturing functions of an organization.

But, after its implementation, many manufacturers experienced significant drawbacks in the MRP II system, which resulted in its failure in the market. The notable ones are:

- It was mainly suitable for make-to-stock manufacturers only

- For make-to-order manufacturers, it only supports medium to large production lots

- Benefits only if the products do not vary much

- It requires clean and precise data entry into the software

- It is less responsive to the production disruptions

Many efforts have been put to overcome these underlying issues of the MRP II system by integrating it with other software like JIT (Just-In-Time) but, it was found that MRP’s rigidity cannot be resolved until the whole system is changed.

It was realized that streamlining every component of manufacturing from planning to production to delivery and accounting, is necessary to get the products of the desired specifications.

And to meet this, ERP systems were designed.

What is an ERP System?

Built on the functionality of MRP II software but with the intent of overcoming its shortcomings, Enterprise Resource Planning (ERP System) is used to better plan, manage, and automate all of the manufacturing processes to reduce errors and improve a company’s production capabilities.

It was battered with technology of integrating and organizing disparate departments of an organization—production, finance, distribution, human resources, etc., to bring about collaboration.

And it indeed has helped employees become more productive and successful in their roles and get real-time visibility into the working of their operations.

The Journey till Today-

During the early stages of its development, ERP concentrated on data organization and process simplification in back-office domains including inventory management, fulfilment, purchasing, human resources, accounting, IT, manufacturing, planning and scheduling, and simplifying other related tasks.

Later, as the Internet became more widely available and used, ERP was further expanded to cover additional business functions like e-commerce, customer relationship management (CRM), supplier relationship management (SRM), supply chain management (SCM), human capital management (HCM), and business intelligence.

Today’s ERP systems assist leaders and managers in better understanding all the moving parts of their operations, identifying opportunities, and making decisions that ultimately accelerates the success and enhances the viability of their companies.

With the advent of cloud and Artificial intelligence, ERPs have gone beyond the role of just streamlining operations. They help expanding business capabilities, taking informed business decisions and improving customer satisfaction all in a pocket-friendly way.

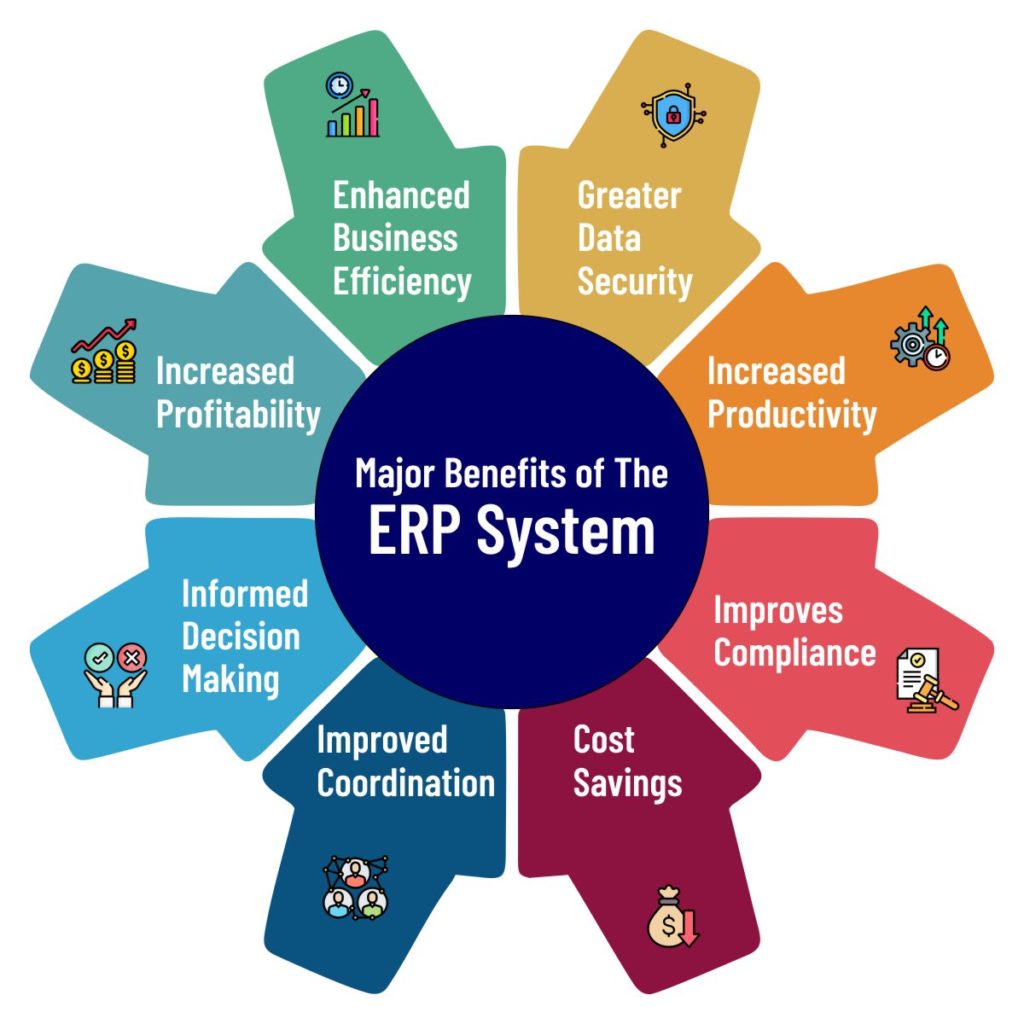

Major Benefits of The ERP System-

This question now ranks the FAQ sections. The following are some of the primary reasons and advantages that have tempted businesses to adopt ERP systems:

Increased Productivity-

ERP successfully streamlines the core business processes & eliminates redundancies, reduces costs, and boosts the productivity of the organization.

Improves Compliance-

It improves production management & offers vigilant tracking of the present quality issues to achieve regulatory compliance easily.

Cost Savings-

It eliminates human errors and inefficient use of time and resources to a great extent—reducing the wastage and costs exceptionally.

Improved Coordination-

An ERP system establishes strong inter-departmental collaboration and communication, facilitating smarter workflows and better execution of routine tasks.

Informed Decision Making-

Implementing an ERP solution systematizes the overall workflow of the organization and facilitates in making of better business decisions immediately by providing real-time information.

Profitability-

A loyal customer base is a sure shot way of gaining profitability for businesses. ERP systems come with a Customer Relationship module (CRM) which helps a business in retaining its customers and stay competitive by communicating and resolving customer issues faster and more accurately.

Enhanced Business Efficiency-

The demand forecasting module of ERP smartly analyses the past demand arc plus the current scenario and based on that predicts the future demand to keep the businesses stay prepared to grab all opportunities.

Greater Data Security-

Secured data is one of the prominent benefits that ERP offers. Instead of keeping the vital information scattered on disparate systems, ERP maintains a central repository for storage. It also has an access control feature that allows only the authorised people to view and edit sensitive documents.

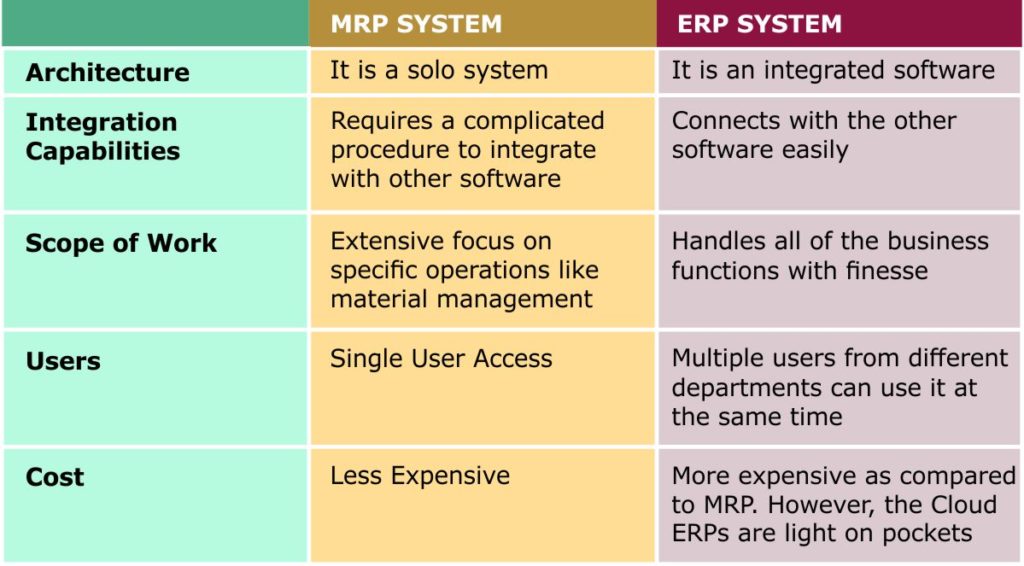

What is the Difference Between ERP and MRP?

Which Software Should Organizations Choose?

When it comes to optimizing business operations MRP and ERP are nearly close to each other. What they differ on is the range of functionalities both provide.

An MRP system specifically focuses on manufacturing processes, while the ERP system is a comprehensive solution and acts as the catalyst for every organizational process.

An MRP system is all you need if your business merely needs support for production processes and stock control.

Otherwise, if your organization needs greater integration to manage all of the core organizational procedures then an ERP solution could be a guaranteed solution for you.

How BatchMaster Can Help Your Business-

BatchMaster is a world-class process manufacturing solution whose every module is thoughtfully designed—keeping the industry best practices in mind, to fulfil the needs of large as well as mid-market process manufacturing businesses.

Switch to the BatchMaster ERP solution and be a significant part of the growth. If you need any assistance regarding its implementation, get in touch with our team of experts today.