Production planning and control is the most crucial part of any manufacturing organization. Impeccable production planning and control not only can avoid wastage but also foster happy customers. But how can manufacturers achieve that? Read the blog to unveil.

In present day business scenario, production planning and control (P.P.C.) plays an important role. It ensures that the business produces right amount of material with set quality standards.

In this blog we will delve into the benefits of P.P.C., factors affecting P.P.C. and the best practices for P.P.C. Additionally, the blog throws some light on the role of BatchMaster ERP in carrying out P.P.C. effectively.

Let us explore everything about production planning and control but before that, here is a list of topics we are going to cover in this blog post.

In this blog post:

- What is Production Planning and Control?

- Benefits of Production Planning and Control

- Factors Affecting Production Planning and Control

- Elements of Production Planning and Control

- Best Practices for Production Planning and Control in Manufacturing

- How BatchMaster Can Help in Production Planning and Control?

- Final Thoughts

What is Production Planning and Control?

Production Planning and Control is a process to smoothen planned production to produce quality products. The term comprises three elements – planning, production, and quality control which are key elements for any manufacturing organization.

It is evident that production planning and control have direct impact on costing of the product, affinity of consumers towards the brand, and profitability of the organization. Therefore, in this competitive market more and more organizations are emphasizing on it.

Benefits of Production Planning and Control (P.P.C.):

Due to its scope, the process has widespread benefits to the organizations. Some of them are directly and some of them are indirectly related to the profitability of the organization. Some of these benefits are like:

Resource optimization:

It helps to make sure that all the resources such as material, equipment, and labor are used efficiently. Organizations can avoid wastage, bottlenecks and enhance productivity by optimizing resource.

Take, for instance, when a manufacturer follows production planning and control process, it can determine how much raw material it must order. By ordering the right amount of material, it can avoid material wastage or material shortage.

Customer satisfaction:

Efficient production planning and control enables manufacturers to meet customer demand in a timely manner. This can help to avoid stockouts, which can improve customer satisfaction and loyalty.

To exemplify, a manufacturer might use production, planning, and control to create a production schedule that ensures that products are shipped to customers on time. By meeting customer demand, the manufacturer can avoid losing customers to competitors.

Cost savings:

Effective production, planning, and control practices can lead to significant cost savings. Organizations can achieve this by minimizing lead time, and wait time, optimally using resources- man, machine and material and thus cutting material wastage plus losses.

Quality assurance:

The process comprises applying quality control throughout the value chain process. Applying quality control can assure that the product meets or exceeds the quality standards.

As a case in point, a manufacturer might use production, planning, and control to create a quality control plan that ensures that products are inspected at receipt from vendor, in warehouse, during production and while delivering.

By implementing quality control measures, the manufacturer can reduce the risk of defective products being produced or in that case, shipped to customers.

Supply chain integration:

Efficient production, planning, and control facilitates better integration within the supply chain. This can help to reduce lead times, improve coordination, and enhance overall supply chain performance.

To illustrate, by applying production, planning, and control only, a manufacturer can assure that the supplier supplies the raw material on time.

This can improve efficiency. Likewise, proper production planning will ensure that the machines are utilized fully, and product is manufactured in due time to avoid any opportunity leakage.

Flexibility and adaptability:

With proper planning, production and control technique, manufacturers can deal with changing demand and trends and adjust its production capabilities accordingly.

For instance, by applying production, planning, and control process, a manufacturer can create an emergency plan to handle surge or shortage in demands.

By having a contingency plan in place, the manufacturer can quickly adapt to changes in demand and avoid disruptions to production.

Continuous improvement:

By analysing production data, identifying inefficiencies, and implementing corrective actions, manufacturers can continuously optimize their processes, enhance productivity, and drive innovation.

Factors Affecting Production Planning and Control:

There are many factors that affect production, planning and control. Some of which are:

Product type –

Complex products require complex production, planning, and control structure as compared to a normal one. For example, manufacturing of steam turbine requires more complex production, planning, and control procedures than producing steam irons.

Volume of production –

Volume of production and nature of production define production, planning and control. Volume depends upon the estimation as per the demands. It helps to reduce manufacturing cost.

Nature of production process –

Depending upon the nature of production, production planning and control can vary. If its customized production, P.P.C. for small processes and production is needed, but if its mass production, P.P.C. will be more intensive.

Nature of operation –

Nature of production impacts P.P.C. If nature involves technical work, it requires high-end machinery and skilled work, whereas non-technical work might require unskilled or semi-skilled workers. Hence, to plan production, manufacturers must consider the nature of operation also.

Seasonal variation –

How seasonal variation will impact production? This factor impacts the P.P.C. a lot as in season time P.P.C. will aim at grabbing as many opportunities as possible whereas, in non-season time, P.P.C. will be like usual process.

Market Forecast –

Meticulous forecast and market analysis can lead to apt P.P.C., whereas a faulty forecast can cause defective P.P.C. There are many more factors that affect production planning and control, but these are the main ones.

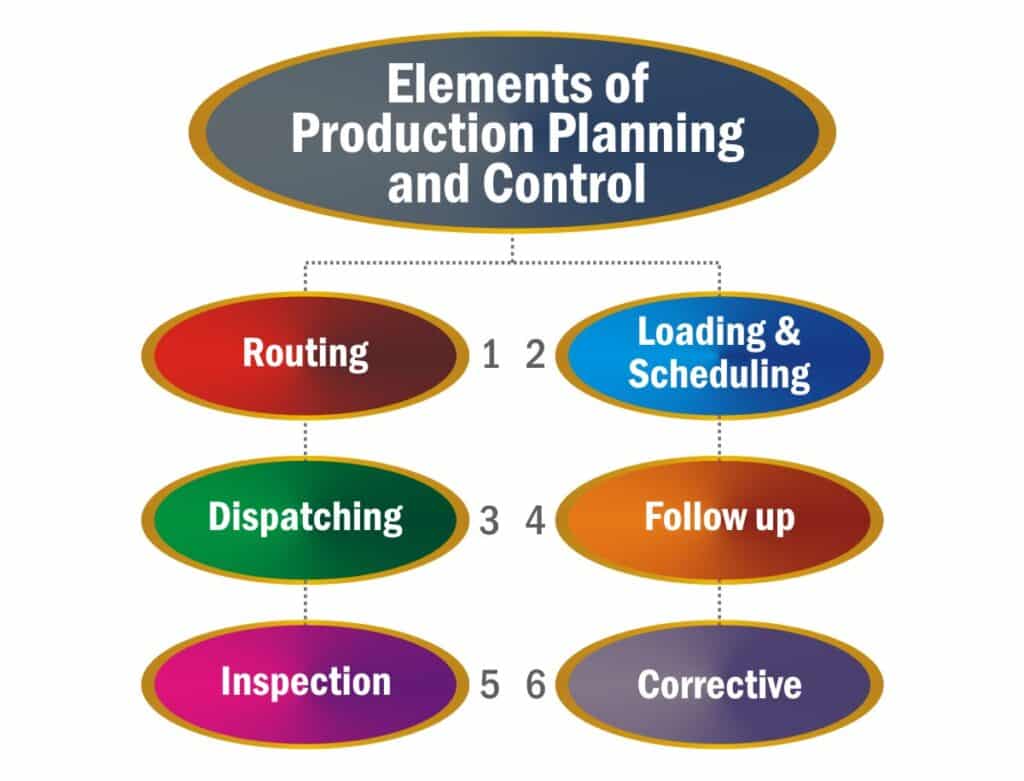

Elements of Production Planning and Control:

Following are main elements of production planning and control:

- Routing

- Loading and Scheduling

- Dispatching

- Follow up

- Inspection

- Corrective

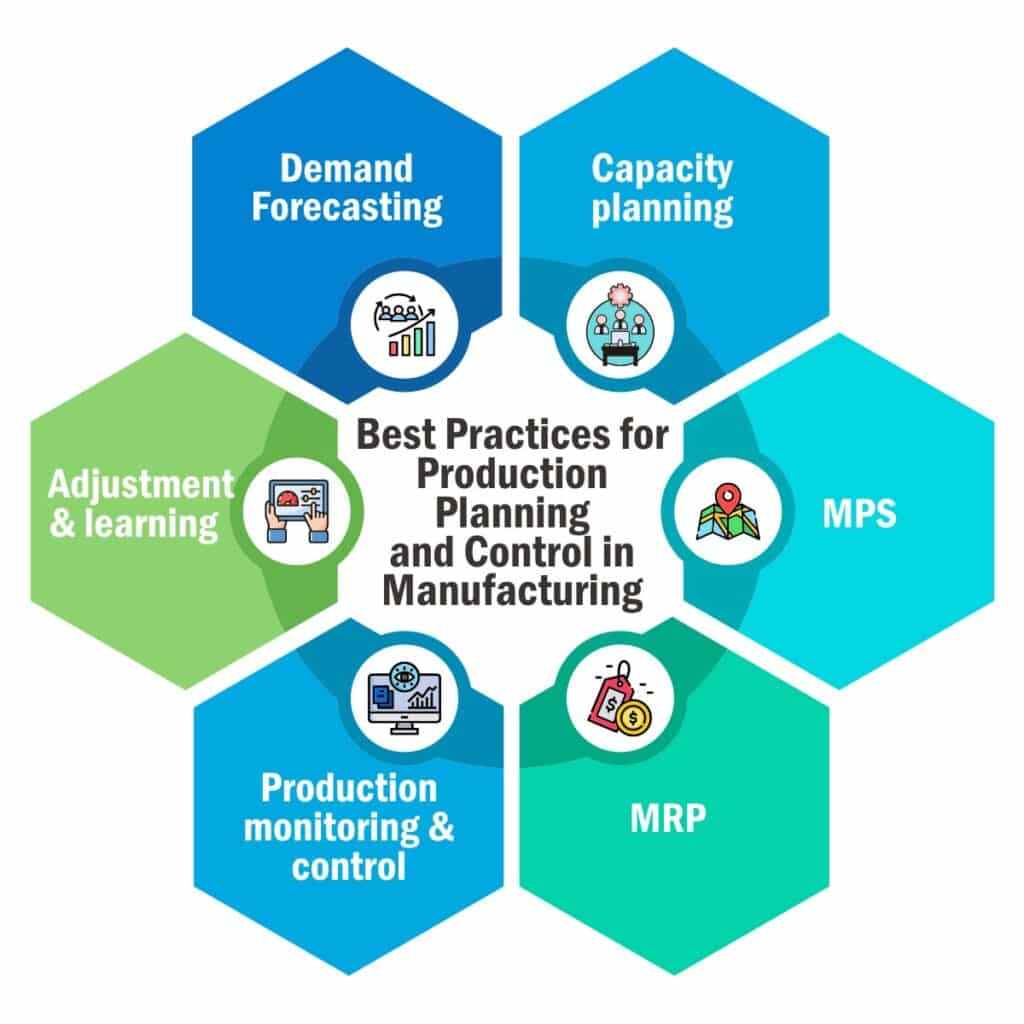

Best Practices for Production Planning and Control in Manufacturing

Demand forecasting –

It plays a crucial role in production planning and control in manufacturing. When manufacturer have exact demand forecasting, it can align its production activities and allocate resources to meet the needs effectively.

A perfect demand forecast will help to have appropriate material in stock, avoid stockouts or overstocking and reduce operational cost.

Capacity planning –

Capacity planning refers to the maximum output that can be produced by a manufacturer to meet the demand. It involves assessing the available resources, like machinery, labour, raw materials, workspace, etc and make sure that it is aligned with the requirements.

The production module of ERP helps to do capacity planning. One can assign the machine, can define working hours of machine, and make meticulous plans.

Master Production Scheduling-

Master Production Scheduling (MPS) is converting the demand forecast into systematic production activity. While doing so, manufacturer must consider machine capacity, raw material availability, and customer requirements.

This shows how much a manufacturer must produce, in what time and to fulfil that requirement what are the raw materials and resources available. With apt MPS, manufacturer can effectively and precisely plan the production activity for current and future demands.

Material Requirement Planning (MRP) –

MRP is a way to manage and plan materials needed for production. It helps manufacturer to determine what materials are needed, when they are needed and how much are needed to fulfil the requirements. It ensures that required materials are available for production.

This practice avoids stockouts, or excess stocks, avoiding probability of loosing opportunity or increasing inventory holding cost.

Production Monitoring and Control –

Production monitoring and control is a process of manufacturing that ensures production activities are executed efficiently, resources are utilized, and quality standards are maintained. It ensures right production, low wastage, good quality output, and efficient use of resources.

Adjustment and learning –

While following the production planning and control, manufacturer can record the findings, and generate reports. By studying those reports and findings, manufacturers can learn and adjust their processes to use resources optimally.

This learning and finding can be the foundation of further improvement and growth. The process is continuous, as market changes continuously. By following it, manufacturers can improve continuously and make better products, that are in line with the consumers’ choice and needs.

How BatchMaster Can Help in Production Planning and Control?

BatchMaster is a process manufacturing ERP that encompasses unparalleled capabilities of production planning and control. By using BatchMaster ERP, manufacturers can plan their production, apply various quality checks on the raw materials, processes, and products, have various pool of verified suppliers, and with the ERP module for production, they can streamline batch production.

Its MRP and MPS capabilities will help process manufacturers to plan production and procurement (if required) precisely. It supports both make to stock and make to order manufacturing.

For any volume of production, BatchMaster ERP provides accurate costing and generates correct report for further analysis. With the help of the software, manufacturers can improve continuously, build the brand affinity, and increase their market share.

Final Thoughts:

Production Planning and Control is a vital process in manufacturing organizations that involves planning, production, and quality control. It is a bedrock of improvement and therefore every manufacturer is aiming to improve it.

With meticulous P.P.C., manufacturers can reap various benefits, but it must be done through a software which supports the production planning and control process, and not through manual or spreadsheet-based methods.

BatchMaster ERP is one such ERP. With more than 30 years of experience, BatchMaster is continuously working alongside manufacturers to improve their processes, streamline their inventory and produce quality products.

If you are one of the process manufacturers, looking forward for a system which can help you to aptly use P.P.C. process, you must think of BatchMaster. Click here now to schedule a call with one of the agents.