To eat good food is a necessity, but to manufacture good food is an art.

There is no substitute for food products with superior nutritional value and excellent quality. And, when it comes to bringing out such high-quality production, managing the shop floor well is the ultimate solution.

The shop floor is among the most important departments of a food manufacturing company. It is where the actual production happens.

However, machine downtime and human errors are also a constant visitor at the shop floor.

Without a streamlined shop floor, the food industry cannot continue to operate at an efficiency that’s needed to generate profits.

That’s where an MES (Manufacturing Execution System) software comes into play.

‘No MES Is a Crucial Thing,’ Said No Food Manufacturer Ever!

A well-designed MES solution not only helps manufacturers to run their shop floor smoothly, but also more strategically.

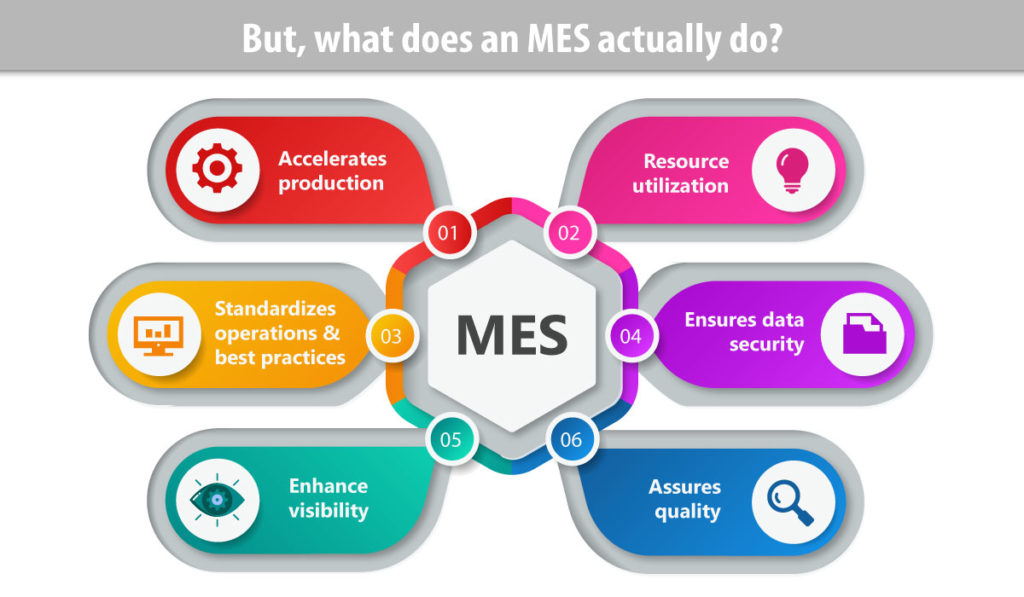

Offering visibility and synchronization of complete end-to-end shop floor processes, MES helps plant managers and shop floor managers to gain real-time insights, perform data analysis, and take right actions for increased productivity, quality, and compliance.

1. Accelerates production

MES records compete information of orders, batches, lots, work centers, process cells, etc. and streamlines the flow of production.

2. Optimizes resource utilization

It records details of personnel like task assigned, working time, certification, etc. to support resource allocation for optimal assignments.

3. Standardizes operations & enforces Best Practices

Whether in a single- or multi-site production, MES helps bring standardization and best practices by guaranteeing that everyone works in the same way, follows same protocols and steps across all plants through same documents, health & safety procedures and workflows.

4. Ensures data security

MES records recipes along with manufacturing instructions, SOPs, and every other related and important information. Moreover, it keeps the data secured by giving access rights only to intended authority.

5. Enhances visibility

An MES maps end-to-end production process, and displays its status in real-time. This helps shop floor managers to analyze the process accurately and take corrective actions for improvement.

6. Assures quality

MES defines quality test at different stages of shop floor production, displays result in real-time, and helps quality managers to identify problems if any and take timely preventive measures.

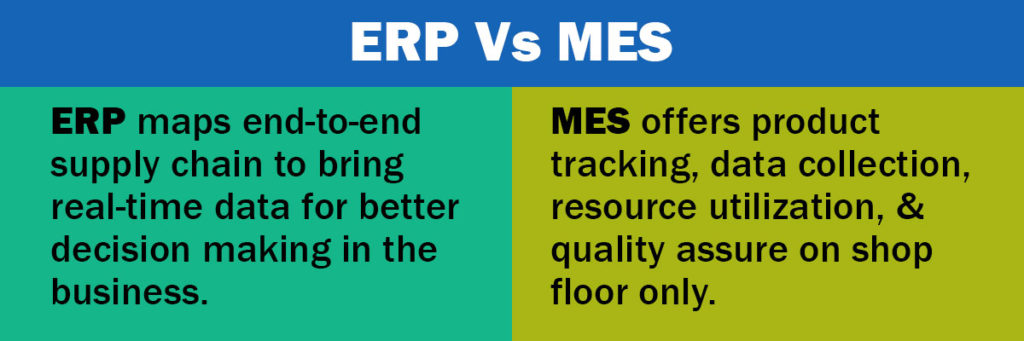

On reading the above information about MES, did you get an impression that it is similar to an ERP? However, there are quite many differences between MES and ERP.

So, what stops MES from matching an ERP?

An ERP is a software solution designed to map entire supply chain, and record complete information at a central repository in real-time.

Under a single big umbrella, it includes range of modules like: production, inventory, sales, purchase, quality control, research and development, etc.

To help manufacturers gain insights, perform data analysis, take timely actions and streamline end-to-end supply chain operations. MES also falls under this umbrella.

On the other hand, MES is designed with a focus on just the shop floor. It synchronizes production with sales demands and procurement of materials.

MES is worth its weight in gold in long run for food manufacturing industries

Definitely, the benefits of MES software in food industry are outstanding in terms of productivity and profitability. To name a few:

- MES ensures complete traceability by recording all transactions, products, orders, and operational information.

- It displays production status in real-time to encourage continuous improvement.

- It helps in improving quality by detecting defects and errors.

- It increases cost savings by reducing rework, scrap, and waste.

- An MES reduces time to market.

- It increases equipment lifecycle and utilization.

Coming to a conclusion

To briefly paraphrase, MES Shop floor systems for the food manufacturing industry help increase efficiency and productivity.

Acting as a standalone and cost-effective platform that consolidates data and collaborate shop floor processes, equipments, and personnel – the software helps plant managers and floor managers to access same information in real-time and take right decision at right time. Undoubtedly, this impacts business’ bottom line positively.

Now, if going through the valuable benefits of MES software makes you interested in getting one such solution for your food manufacturing business, try BatchMaster MES.

Designed to offer complete operational control and end-to-end visibility, BatchMaster MES is a perfect-fit for shop floor of any food manufacturing business irrespective of its size.

What’s more, it can be scaled and customized to meet the business’ unique needs. For more details, reach the experts now!