Imagine this- you have received a big customer order, and you’ve started working on it to deliver the products on the set deadline. But, you somehow failed in delivering the order on committed date.

Reason: Poor planning, that lead to insufficient raw materials, production halts and thus, delayed delivery.

RESULT: Lost Sales | Unsatisfied Customers | Brand Reputation Damages

Being a production manager, dealing with such situations can be nothing less than a nightmare. To summarize this, manufacturing organizations must plan and regulate their production processes in order to fulfill client demands and achieve their goals. This makes us also say that production planning is at the core of a profitable company’s success story.

Table of Content:

- Overview

- What is production planning?

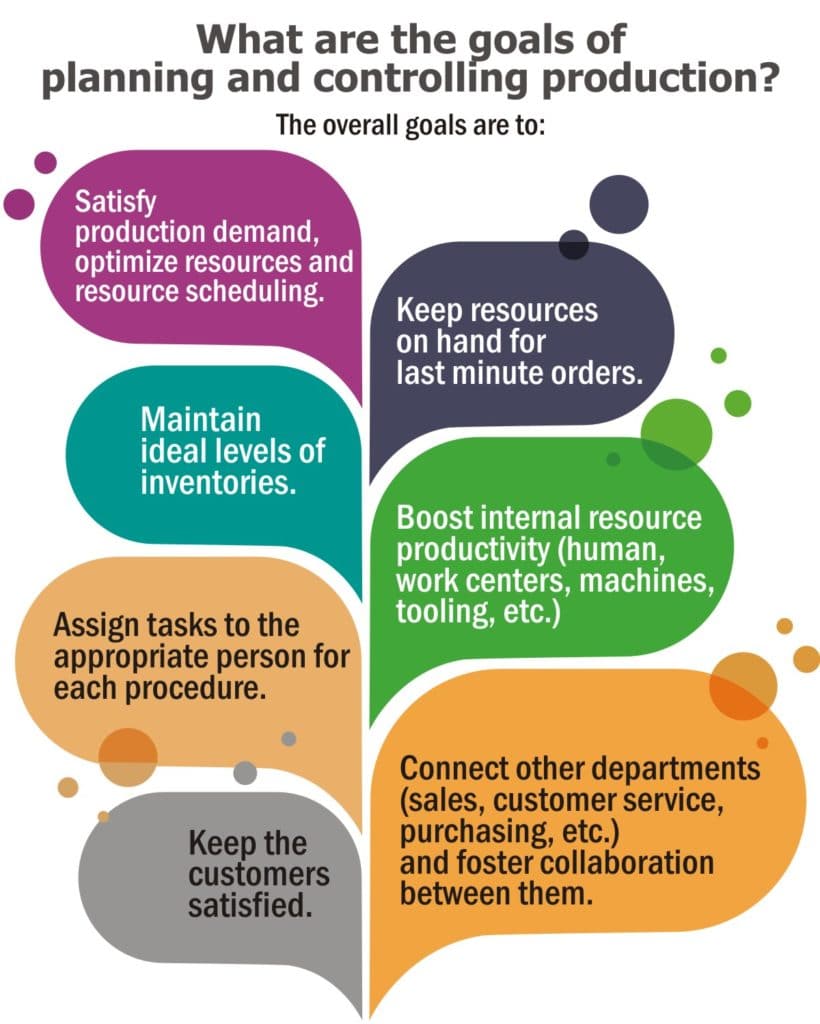

- What are the goals of planning and controlling production?

- What is the production planning module in ERP?

- How does the ERP system help with the production planning of your manufacturing industry?

- How BatchMaster ERP helps with MPS/MRP?

- Summarizing thoughts

Overview

There is a quote that says, “If you fail to plan, you plan to fail”

Rightly said. If you don’t plan ahead of time before performing operations, you are likely to fail because nothing can be done precisely and accurately without actually planning for what has to be done.

And, when it comes to manufacturing businesses, not planning production processes will certainly result in failure.

Manufacturers must plan resources in terms of men, materials, and machines accurately and efficiently so that each entity can function individually.

To put it another way, a precise and accurate production plan is the key foundation stone that helps businesses organize their resources and effectively manage the costs, time, and other resources involved in the manufacturing process.

Production planning basically means knowing when, where and how much to order considering various sources of demand and supply.

It includes a wide array of activities -right from the ones taking place on the shop floor to the delivery of the final product at the customer’s door.

And, needless to say, all these activities reach their full potential only when the organization has an effective production plan in place.

Continue reading to learn more about production planning, how ERP can manage it, and what is the ideal solution for accomplishing it. Let’s first discuss production planning and management part.

What is Production Planning?

The allocation of raw materials, resources, and processes to manufacture products within certain constraints and deadlines is termed “production planning”.

It aims to achieve maximum efficiency by cost-effectively combining production demands with available resources.

It involves planning and estimation of:

- Inventory and sales levels

- Production management using targets

Production planning optimizes manufacturing processes to make the entire manufacturing process as efficient as possible.

Doing this manually or using best-of-breed independent software result in errors and inefficient plans, However, technological tools such as Enterprise Resource Planning (ERP) help in achieving this objective precisely.

An ERP software streamlines and integrates all of the resources needed to manufacture products and services.

Manufacturers can effectively manage and optimize these resources with complete visibility and get complete control over customer-driven deadlines, configure goods to order, manage inventories more effectively, and run the shop floor more efficiently.

What is the Production Planning module in ERP?

Production planning module in ERP software helps manufacturers to work more proficiently by efficiently managing internal resources in order to meet customer orders or demands.

It determines what to produce when to produce, and how much to produce.

By managing production activities, manufacturers can also determine production capacity and the raw materials, bill of materials, or substitute bill of materials that are required to satisfy demand.

Production planning and control manages and schedules the allocation of human resources, raw materials, work centers, machinery, and production processes.

It finds the most efficient way to produce finished goods considering the various lead times to meet production demand. It then creates a feasible manufacturing plan which the business follows.

How does the ERP system help with the production planning of your manufacturing industry?

As discussed above, the production planning function of an ERP system helps in making the best use of all resources to ensure that production is not hindered.

It comes with the Material Resource Planning (MRP) and Material Production Scheduling (MPS) module, which helps manufacturers accomplish planning for production and the materials required for that production plan.

MRP helps in finding an equal balance of raw materials to meet demand, both for now and in the future. The pressure is always on the producers because if they misjudge the demand, they will run out of raw materials and their customers will search for substitutes.

At the same time, if they estimate the quantity needed too high, it will waste money on both excess inventory waste and space obstruction.

On the other hand, MPS provides the means to plan the production cycle based upon forecasts, demand and available stock.

It ensures that materials and components are available when needed in the production process and that manufacturing takes place at the right time to meet the deadline.

Based on the schedule, it calculates the quantity required for the item. It then carefully checks for how much quantity of that order is already available, how much is ordered and expected to be received before it is needed or if it is available at other warehouses of the company and can be procured from there. Deducting the quantity available/expected, it recommends ordering the balance quantity.

The objectives of MPS can be consolidated as follows:

- Balancing demand and supply

- Avoiding unnecessary inventory

So, on the whole, both of these functionalities blend in together to help business plan their production starting from MPS that plans the production and becoming an input source for MRP that checks the availability of resources to scheduling the production cycle by looking into the calendar dates.

MPS helps in planning the orders in terms of batches and lots while seeing the machine’s output and throughput value.

The ERP system while conducting MPS checks planned and dependent demands along with the date range.

As soon as the material are planned, the MPS process starts with defining the calendar by considering the estimation of forecast, demand, production, and purchase.

The planning can be done across a length of calendar to include immediate and future needs. The sources of demand and supply can be determined so that the planning includes precisely everything.

The plan derived from all these inputs, can be worked upon to accommodate different scenarios, like changing the forecast or increasing the lead-times, expediting the orders etc.

The system dynamically recalculates in no time and offers a new plan, which can be converted to production batches or purchase quotes in a single click.

The end result of the entire process is optimized inventory, reduced waste, improved inventory turns, and better working capital use, which facilitates cost reduction.

Manufacturers may save a lot of money and even eliminate leasing fees by just keeping the amount of inventory that is necessary.

The money saved can then be spent elsewhere, for other profitable tasks associated with the firm.

How BatchMaster ERP helps with MPS/MRP?

BatchMaster is a batch manufacturing software that includes a Production Module which virtualizes batch information, improves efficiency, and synergizes between software and actual operations.

Based on sales forecast, planned purchase and production orders, inventory statuses, and work orders incorporating bill of materials down to the lowest level, BatchMaster ERP software’s MPS/MRP module helps manufacturers compute and maintain an optimal manufacturing plan for what they need to produce, how much they need to produce, and when they need to produce it.

Through scheduling dashboards, it gives manufacturers access to a complete picture of anticipated orders with drill-down, analysis, grouping, and rescheduling options.

This gives them the ability to establish a relationship between demand and supply and to decide when and which batch operations are necessary.

With BatchMaster Material Planning module you can:

- Effectively plan production and procurement activities

- Maintain optimum inventory levels

- Reduce inventory carrying and procurement costs

- Ensure production expected yields are met

- Increase customer service levels with timely deliveries

Summarizing Thoughts

A production manager’s job is both rigorous and stressful. It can, however, be made easier with the help of BatchMaster ERP – a well-known production management software for reducing the difficulties of production.

The software is loaded with a comprehensive Production Planning Module that ensures the aforementioned points are well taken care of, consolidates batch information, increases efficiency, and reduces the gap between software and actual operations.

It caters to the unique needs of your single and multi-plant, multi-location, and multi-company business. It supports, manages, tracks, and controls all production processes, from batch creation through allocation, inspection, and quality control, and ultimately closure, with its extensive collection of capabilities.

With its automated batch size and material replacement, it can also handle last-minute configuration modifications or changes in client requirements.

It also keeps you up to date by providing rapid access to a huge variety of reports and dashboards.

Get BatchMaster ERP today and enjoy the benefits of end-to-end production management. Feel free to write to us at sales@batchmaster.co.in, or visit our website to know more about it as well as our other products.