Attention manufacturers!!! If you’re not cautious in managing inventory, it may cost you time, money, and perhaps your business. Poor inventory management can be a secret profit killer in your manufacturing business. However, inventory management software can be a savior and help you in minimizing this situation enormously.

Table of Content

- Overview

- What is inventory management?

- Consequences of NOT Having Inventory Management system

- What is the Inventory module in ERP systems?

- How BatchMaster ERP helps in managing inventory completely

- Concluding Thoughts

Overview

Do you know that inventory, in addition to machinery, manpower, fleets/trucks, and other handling equipment, is considered a company’s asset which is controlled and documented using the company’s datasheet? And so, it is equally important to handle inventory and assure that the right level of inventory is in the right place at the right time. All this comes under Inventory Management.

Continue reading this blog to discover more about inventory management, the repercussions of poor inventory management, and how ERP can help businesses with inventory control.

What is Inventory Management?

Inventory management, also referred to as stock control is the process of ordering, storing, and using the company’s inventory efficiently. Here, the stocked goods, inventories, and non-capitalized assets are properly arranged and managed according to their specific shape and placement.

Before knowing how ERP helps in inventory management. Let us first learn about the real need of managing inventory –

- To optimize inventory, reduce costs, and streamline entire supply chain operations.

- To sync warehouse activities with other business operations and create one cohesive unit that allows efficient running of the business.

- To eliminate duplication in ordering stock.

- To minimize loss through deterioration, pilferage, wastages, and damages.

- To ensure a continuous supply of materials and stock so that production does not suffer.

- To avoid both overstocking and under-stocking of inventory.

Now that we know that handling inventory is an important aspect of business operations, it’s evident that it can’t be overlooked at any cost. And so, to effectively manage it, businesses must implement an inventory management software.

Such software track items from the moment of purchase through their time of use and delivery to the customer. The best inventory management systems should include complete and detailed records of materials and items so that they can be tracked and used efficiently.

[wp-video-popup

video=”www.youtu.be/Z1D8h3tuR8o”]

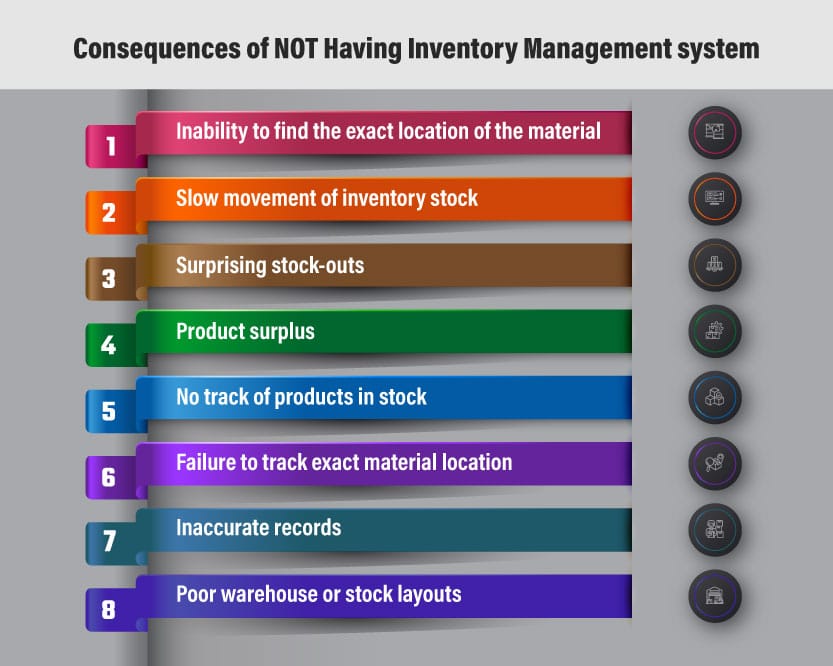

Consequences of NOT Having Inventory Management system

Businesses risk incurring expenditures and other inefficiencies if they do not use an inventory management system. Let’s have a look at the consequences for them:

- Inability to find the exact location of the material, leading to the consumption of a huge amount of time and time in searching for the material and ultimately facing ‘delay in deliveries.

- Slow movement of inventory stock, takes up valuable storage space, eating the company’s bottom line.

- Surprising stock-outs, resulting in supply chain backorders, lost sales, and dissatisfied customers.

- Product surplus, leading to excess inventory levels and increased carrying costs due to more use of warehouse space and product maintenance.

- No track of products in stock, because the primitive business methods can’t manage the growing demands of the business.

- Failure to track exact material location results in time wastage in searching for the material, and delayed deliveries.

- Inaccurate records (wrong part numbers, incorrect inventory counts) result in manual documentation errors.

- Poor warehouse or stock layouts can increase stock-picking time and increase in labor costs.

But, with the right technological solution such as a well-designed Inventory Management Software, all of these inefficiencies can be eliminated. Let’s now take a look at the advantages of the inventory system.

- Tracks inventory levels across an organization’s entire length and breadth, regardless of size or locations, or plants.

- Produces real-time, accurate, and detailed reports on data such as current on-hand, safety stock, inventory production, inventory to be procured, and so on.to keep the perpetual and real inventory in sync.

- Perform Physical as well as cycle counts

- Syncs multiple inventory locations and provides a consolidated view of stock levels across all warehouses, distribution centers, retail stores, and suppliers.

- Generates alerts when inventory levels fall below the minimum set thresholds or reach expiry, preventing material scarcity.

- Enables managers to trace products by date and location by using lot or serial number records.

- Increases product visibility during recalls.

- Analyzes critical inventory in real-time and ensures continuous production

- Provides an end-to-end view into orders through all departments, from sales to accounting to fulfillment.

- Plans production and creates purchase orders while taking into account lead times, resource availability, delivery date etc.

- Provides trend-based analytics and aids in forecasting stock requirements.

What is the Inventory module in ERP systems?

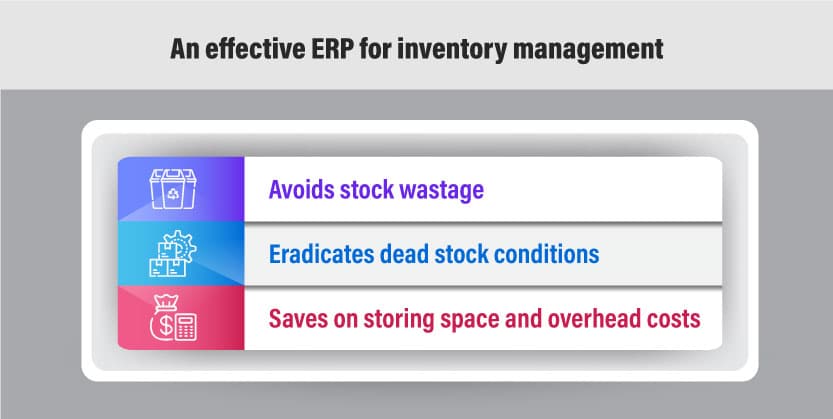

The inventory management ERP module ensures that the inventory is optimized taking into account various sources of demand and supply. The ultimate goal of inventory module is to minimize the cost of holding inventory by telling when it’s time to replenish products or buy more materials to manufacture them.

Long story short- striking an adequate balance of inventory is the need of an hour for any business to drive revenues. And this can be achieved by having an inventory management ERP module.

Following are some of the ways through which an ERP can help with inventory management:

- Real-time and multiple product location tracking:

Inventory management software helps manufacturers in tracking inventory levels across the entire length and width of a company, irrespective of company size or number of locations.

- Produce/Purchase items at the right time:

ERP provides details about the various sources of supply and demand. It efficiently plans production and purchase orders, taking into account varying lead times, resource availability, and delivery dates. Moreover, long-term planning can save you from last-minute expensive buying, instead, ERP suggests procuring during the season or when offers or promotions are going on at the vendor’s end. This saves a good amount of time and money.

- Right handling of surplus inventory:

Surplus inventory needs immediate action. A slight delay might mean manufacturers have to dispose of the surplus, i.e., wastage of their money. And ERP helps in this as well. It provides real-time access to surplus inventory and enables manufacturers to examine it. Kits can be created by pairing such surplus items with fast running items. Even promotional offers and discounts can be maintained, tracked and costed in an ERP.

- Avoiding Scarcity:

Managing large and fast-moving product lines, as well as addressing last-minute requests, requires managing safety stocks. And an ERP that incorporates an inventory module in it is the ideal tool to handle this. When inventory levels drop below the minimum set thresholds, it sends out notifications, so that stock-outs can be reordered before they evaporate.

- Classification and tracking of inventory-

Businesses can use ERP software to create and classify groups based on product characteristics or features/attributes. The system also has a feature that allows businesses to manage inventories using lot serial numbers, bin numbers, and pallets. When you’re looking for a product, simply feed the numbers and identify the specific location where it is stored.

- Warehouse Management-

The inventory module in ERP software facilitates day-to-day warehouse operations simpler. It allows businesses to remotely execute and track specifics of various warehouse activities, increasing inventory visibility and improving inventory accuracy. By integrating with handheld devices, it lets you track inventory even at the remotest corner. This even lets you register transactions in your panoptic warehouses right when and where they are happening, without the need to go to the workstations time and again to record them.

- Quick & accurate generation of reports:

ERP delivers real-time, accurate, and thorough reporting on inventory levels, such as current on-hand, safety stock, inventory production, inventory to be procured, etc. This helps the manufacturer in avoiding both over-stock and under-stock situations. ERP also accelerates product recalls and ensures comprehensive product traceability by tracking inventories throughout the supply chain.

How BatchMaster ERP helps in managing inventory completely

BatchMaster ERP is a business management software that enables process manufacturing companies in streamlining and automating their supply chains. This ERP software has an inventory management module that facilitates product tracking across the company’s entire supply chain. It tracks and traces the product’s whole journey, say from order placement with the vendor until order delivery to the customer, and also improves the entire spectrum.

The transparency of this software has a significant impact on a business’s bottom line. By effectively tracking products, businesses can reduce waste, identify trends, and make rational investment decisions.

BatchMaster is the right fit for manufacturers that produce food, pharmaceutical, paint & coatings, specialized chemicals, or personal care & cosmetics items and are seeking ERP software to make their operations effective. For over 30+ years, we’ve been providing process manufacturing companies with a decisive advantage over their competitors through a variety of industry-specific and micro-verticalized ERP software solutions. For a free consultation, contact us at sales@batchmaster.com.

Concluding Thoughts

ERP software has proven its worth when it comes to addressing crucial difficulties encountered by businesses, thanks to its numerous priceless capabilities, inventory being an important one. Hope this blog was successful in explaining how ERP can help process manufacturers meet their inventory management needs.