The business environment is rapidly changing and becoming extremely competitive.

Organizations can no longer afford to take a lot of time to develop and introduce their products to the market.

Also in line with the various business processes, which too are getting more complex with time, the products are also evolving and getting more advanced.

This has created a need for the businesses to have a better operational model to support the product development, precisely because in its absence, it will be challenging for the businesses to manage all the different aspects of creating a new product.

And in such scenario, product development will inevitably run late and exceed its budget.

The need of the hour for the organizations is to make the product development process more transparent and improve the efficiencies.

This will lead to more innovations, shorter product development cycles, and faster time-to-market, among other things.

And what helps them in achieving all this? A PLM system.

Product Lifecycle Management (PLM): Definition

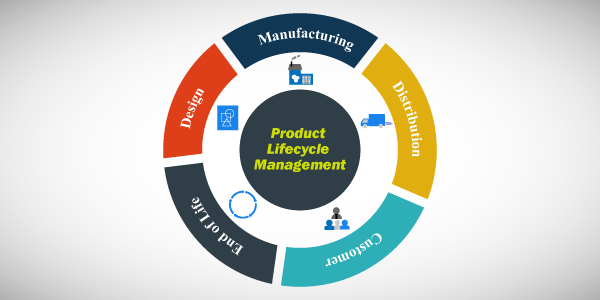

Product lifecycle management (PLM) can be defined as the process of managing the complete lifecycle of a product.

Right from its beginning, through design and production, to disposal of the final product and service.

In other words, it is a tool that provides control of the product record across all the development stages such as conception, designing, and production.

With the help of this system, companies can manage their entire product data, including items, bill of materials (BOMs), and product files.

It also helps in tracking changes related to product information and communicates revisions to the supply chain.

By putting the PLM system in place, organizations can handle key product decisions like real-time product changes.

It combines, organizes and tracks the complete product data — which is dispersed throughout the organizational departments and puts it in a centralized location.

Manufacturers can get access to the single and the correct version of their product record at any point in time by capturing product data in a PLM system.

To put it simply,

Product lifecycle management combines all the organizational data, processes, resources, and systems into one and provides product information to the organization.

The process be broken down into the following stages:

- Beginning of life (BOL), which involves new product development and design processes.

- Middle of life (MOL), which includes association with suppliers, product information management (PIM) and warranty management.

- End of life (EOL), which includes approaches for how the products will be obsolete or recycled.

Benefits of Product Lifecycle Management

A PLM system can help an organization efficiently manage their product’s lifecycle by providing a data warehouse for all the information related to the product.

It can be used to automate product-related data and integrate the data with other business processes such as ERP software.

It works on the lean philosophy and its objectives are to eliminate waste and improve efficiency.

The Benefits of a PLM System for an Organization are:

- Development of customer-centric products

- Competitive pricing, traceability and better quality

- New market development

- Shorter time to market

- Lower product cost

- Lower lifecycle cost

- Increased productivity

- Accelerated revenue growth

- Development of innovative products

- Reduced compliance risks

- Waste reduction

- Improved efficiencies

Product Lifecycle Management & Enterprise Resource Planning

An ERP and a PLM system go well together, acting as collaborative tools that can work with each other and support the different requirements of a business.

- PLM is product-specific, more focused on the creation of a product or the product line in particular, ERP is enterprise-specific and has a broader scope, which involves gathering information and tracking a business’s resources throughout a year/cycle.

- PLM focuses on managing the development of the product, while ERP manages the resource planning for production processes.

- PLM system stores the initial product data such as product design, and once it is ready to be produced, the ERP system, integrated with the PLM, comes into play in order to manage the resources.

According to a CIM Data report, a PLM—ERP integration across the enterprise can result in:

- 75% reduction in terms of time, cost, and efforts associated with entering data from one system to the other.

- 75% reduction in the BOM-error cost, since BOMs are created only once and then managed consistently across both the PLM and ERP systems.

- 15% reduction in inventory cost, since designers and engineers are aware of which components are already on hand.

- 8% reduction in scrap generated.

Since PLM manages product development, and ERP aims to manage the resource planning for production, it is fair enough to use these tools in sequential order.

But if the sequence is not followed and ERP software is implemented before a PLM, the risk of entering inaccurate product data details to an ERP system, inefficient costs, product recalls, and breach of compliance regulations gets high.

By integrating ERP software with PLM, the updated product data is available at any time and can be shared with the necessary departments.

This ensures accurate financial planning of the organization.

Thus, both an ERP system and a PLM system, are important aspects in a company’s growth and innovation.