Handing orders and delivering up to the satisfactory level of customers is very important for a business. When businesses fail to do so, they put themselves in a detrimental situation.

In present context, when customers have many touch points, managing all orders efficiently is key to success. But how can businesses achieve that? Follow to explore.

What is Sales Order Management?

Every time a customer places an order, there are a chain of processes that take place at the background which ensure that the order is captured, processed properly and product is shipped in time.

These chains of processes are called sales order management.

Fundamental of Order Management-

Order management stands upon two fundamental ideas –

- Ability to support growth.

- Maximising efficiency.

Both are dependent upon each other. A company cannot grow if it does not have efficiency in order management and, to achieve efficiency in order management, the company should inject newer technologies which is possible only when it is on a growth track.

Why Order Management is Necessary?

In present day where customers have multiple options and choices, speed of delivery and quality of product are real differentiators.

Prices take back seat when these two are met. This is the reason why many manufacturers charge more than their competition.

Good quality product can reach to customer on-time only when sales order is managed properly.

Even a single break or time lapse in the processing can switch the client from saying Yes to absolutely reject it. Therefore, if a manufacturer wants to retain its client, order management should be his priority.

Secondly, order management helps businesses to optimize inventory.

Business can easily avoid over stocking and grab maximum opportunities as they can see the trend and predict the orders.

This will help businesses to work in precise budget, expand growth envelop, and smoothen cashflow.

How to Achieve Order Management?

Achieving sales order management manually is not possible, especially in present times when customers have many channels of purchase.

As business grows, calculation, and complexities grow as well. Managing them all require technological assistance.

Here comes the role of a software which manages sales order in an efficient way, automizes lot of processes and saves huge time.

Besides, it consolidates demands coming from various channels and makes a streamlined flow for proper management.

This software is known as Order Management System or Order Management Software or OMS, and this is the key to achieve order management.

An OMS software allows to manage inventory, warehouse, finance, shipping, and customer related information.

How BatchMaster helps in Sales Order Management?

BatchMaster ERP is a complete end-to-end ERP solution with a comprehensive Sales Order Management Module.

It has the capability of registering a new inquiry in digital form under the name of prospect. User can add details of the prospects viz address, contact details, class, terms, tax, territory, card details etc.

User can also define credit limit of the prospect.

Along with the details of prospect, user can add information and details of salesperson giving services to the prospect.

This detail will include sales commission (basis sales and gross profit), and various information of salesperson.

Later in the stage, if the client shows inclination towards buying the product, the prospect is converted into customer with all the prefilled information.

BatchMaster allows single click conversion of prospect into a customer without the need of filing up the details again.

This saves a lot of time of filling information, while also providing the sales executive with the last conversation or quotation shared.

This feature comes very handy when one salesperson is handling many queries in a single day, or the prospect turns up after a long interval.

Creation of a Quotation –

A quotation is the start of the sales order cycle; however, it is an optional step and can be sent to a prospect as well as a customer.

Commission, tax, discounts, offers, prices, extra discount, terms, freight charges, etc can be defined and added on the order with just a click.

Approval workflows can be incorporated to seek approvals before sending quotation to the prospect or customer.

Once the quotation is approved by Sales Manager, basis offered rate, discount, taxes, terms, contract price etc, then it can be mailed directly to the concerned prospect or customer.

A quotation can again be negotiated by the customer and another version can be sent to the same customer/prospect.

Creation of Sales Order –

A sales order is the next step in the process. Some companies directly create Sales order and do not need the quotation.

If a quote is created, the (BME facilitates to create a customer group or customer class and can fetch information of all customers lying in that group.

This facility helps to locate a customer faster or apply discount or offers on a particular customer group altogether.)

Once the quotation is accepted by customer, the quotation is converted into sales order at a single click. This ease of conversion of a quotation into sales order helps user to process fast.

The sales order empowers to change various fields related to rate, tax, freight etc before finally sending it for processing.

BatchMaster ERP allows users to create multiple sales orders simultaneously. This functionality is very helpful when orders are coming from various channels.

A new sales order by minimizing the old one and toggle among various sales orders.

Did we tell you about the BatchMaster’s Web Version?

It is the version of BatchMaster accessible over mobile phone or tablets.

The benefit?

It lets your sales representatives enter sales order right from the field, check the inventory status and make true commitments, and even stay updated with all latest progress even when they are away from office.

Sales order thus created can either be sent to picking and packing, if adequate quantity of product is available in warehouse, or it can be sent to production, if adequate quantity is not available.

Let us understand both scenarios one by one.

Creating Production Batches from Sales Order –

BatchMaster ERP (BME) can directly create a production batch from sales order. Many sales orders can be merged together, and a single batch can be created for them.

Goods so produced will be sent for picking, packing, and shipping directly against the order.

One of the unique features of BatchMaster ERP is that it can accommodate customer specification and create a separate batch to meet the unique demand.

Lots produced in such conditions can be locked in for specific order.

For e.g., if a customer specifically requires mint flavoured chips, then A separate specific batch can be created for the customer and the chips so produced will be directly assigned against the order.

This capability allows manufacturers to keep special demands separate and not mix it with regular production.

Picking, packing, and shipping-

For any warehouse to be ready to send products for shipment, there must be first picking, then packing and then shipping.

Picking and packing- With the help of BatchMaster ERP, users can generate a pick list, pack slip and GRN.

This pick list helps warehouse personnel identify which product is to be taken, from which lot number, from which warehouse and bin and in what quantity.

The picklist serves two purposes –

- Ensures that exact product is picked in exact quantity for packing and shipping. Since, objects to be picked are well defined, the process is speedy, accurate and timely.

- Eases backtracking the product. With the help of this pick list, user can identify the lot from where the product is picked, and with that lot it can backtrack up to the raw material and vendor, if required.

Before finally sending the product to the shipment, BME allows users to apply Quality Checks to be ultra-sure of the quality of shipment.

On the QC pass goods are allowed for shipment and a COA can also be generated plus attached to the shipment for case-specific requirement.

Shipping

BME allows to print bill of lading. Besides, it allows shipping of a single sales order in parts, subject to availability of stock.

BME allows to print POD, and order acknowledgement. It also facilitates multiple shipment. This feature speeds up shipment process.

So instead of shipping for individual sales order, user can do it for bulk orders, provided picking (selection of lots) of all the sales orders have been done individually.

BatchMaster ERP can generate packaging documents for all goods shipped to a customer.

A delivery tracking number can be stored to access the shipping status within the delivery note with click of a mouse.

As the sales order progresses from picking and packing to shipping, the status of the sales order is changed accordingly.

This helps to immediately track and identify the real-time status of a particular sales order and become more responsive towards the customer queries.

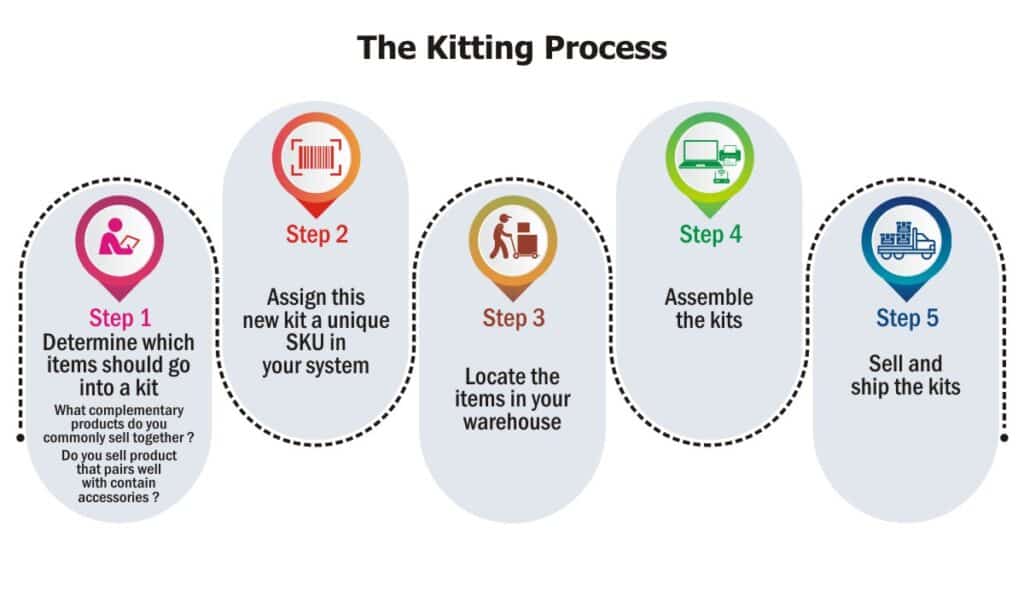

Sales kit –

BME has unique feature of creating a sales kit. Manufacturer can club two or more products to make a bundle and charge for the whole kit.

This facility is useful when clubbing of products is required when a new product is to be launched in the market for sampling/promotional purposes or to clear the inventory of non-running items.

e.g. a new masala pouch can be clubbed with pack of noodles, or a conditioner can be clubbed with shampoo to promote it.

Invoicing –

After shipping, the invoice is generated. BME allows to make single invoice for multiple sales order of a customer. This feature is known as super-invoice.

Invoicing automatically calculates the amount to be received (AR) basis various agreements, terms, discounts (line discount, extra discount, another discount), promotional offer etc.

Once invoice is done, GL is fired which updates the inventory and cost of inventory. It reduces on hand quantity in warehouse giving a real-time view of inventory

Return-

BME effectively handles returns. It settles on hand quantity in inventory, fires GL and adjusts accounts. The process is seamless and easy with BME.

Generation of various reports-

Besides managing sales order effectively, BME provides various reports. It provides dynamic opportunity-analysis report, which will help businesses to readily spot trends and patterns of sales opportunities.

These reports give fair idea of best-selling items, sales analysis, seasonal selling, market response towards new launches and helps management to further tweak processes for better outcome.

Conclusion-

BatchMaster is an ideal ERP for process manufacturers. It is available on Cloud too, therefore serves as an amazing cloud-based order management system.

It can give you a competitive edge by replacing traditional order management methods with fully automated software solution.

It can confirm and process shipments, partial shipments, and back order; handle return cases very well, check inventory for availability plus immediately update the inventory and do lot more.

Power-packed with order management system qualities, BatchMaster is the pioneer in formulation, manufacturing, distribution, finance, quality, and compliance capabilities too which is the core of any process manufacturer. If you want to know more about BatchMaster, contact us.