Inventory directly relates to money and eventually to the success of the business. A successful business manages inventory so effectively that it creates happy customers who become brand custodians.

Do you aspire to take your business to that height? Follow the blog to learn everything about inventory and its management.

In this fast-evolving landscape of business, strategies, and dynamics for managing operations are also changing rapidly. But, out of all, good inventory management has always been a critical move toward keeping businesses profitable and productive.

However, adopting manual & outdated methods for tracking and managing inventory can’t keep up with today’s speed of commerce. Organizations need smarter, more agile systems, to maintain optimal stock levels, reduce waste, and meet customer expectations with consistency.

As we step into 2025, emerging technological solutions like Enterprise Resource Planning (ERP) software offering unparalleled automation, predictive analytics, IoT-enabled real-time tracking, AI-driven forecasting, etc., are helping manufacturers transform the way manufacturers work toward managing their inventory.

The level of technological advancement ERP software induces into operations, not only helps businesses keep their inventory shelves stocked but also enables manufacturers to stay informed and make proactive decisions, keeping businesses profitable and sustainable.

This blog helps you dive into the fundamentals of inventory management and how an ERP software helps manufacturers overcome the challenges they face. So, slip in the details to explore.

What is Inventory Management?

The process of keeping track of and managing all the goods a company has in stock is known as inventory management. Along with the system and processes, organizations keep track of their inventory; it involves all the goods a company currently has or the ones that are on order.

This is done by inventory management software, usually an ERP like BatchMaster ERP, which helps record and track inventory levels, sales, and purchases.

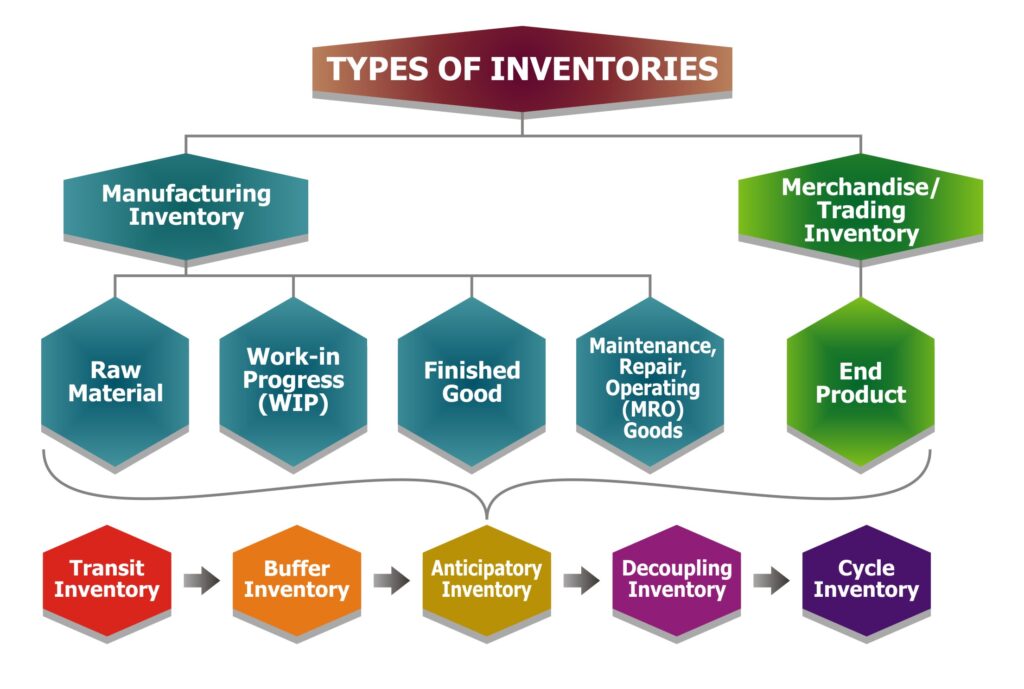

Type of Inventory –

The type of inventory largely depends upon the industry in consideration. For a logistics or merchandising industry, inventory is the end product that needs to be delivered to customers.

For manufacturing industry, inventories are raw material, sub-assemblies (WIP), finished goods, MRO goods (maintenance, repair, and operating goods), transit inventory, buffer inventory, anticipatory inventory, decoupling inventory, and cycle inventory.

Let us understand each type for more clarity.

Raw material –

These include materials used to produce intermediate and finished goods.

Work-in-progress (WIP)–

These are the raw materials that are in the process of being turned into finished goods.

Finished good-

The product is ready to be delivered to the customers.

Maintenance, Repair, Operating (MRO) goods–

It refers to supplies, spares, and other materials needed to perform regular operation and repair work. This inventory is important for the smooth running of business.

Unlike raw materials, MRO goods do not become a part of finished goods.

Transit inventory–

Inventory which is in transit refers to this inventory. After receiving, such inventory rests in the warehouse.

Buffer inventory –

It is the extra inventory kept at bay to meet the surge in demands. It expels the probability of stock-out and helps in smooth business function.

Anticipatory inventory-

Based on past market trends, expected surges in prices, or deficiency of materials, if businesses invest in some stocking, then such inventory is known as anticipatory inventory.

It is usually the raw material or the finished goods.

Decoupling inventory–

It is the term used for extra inventory kept at each production line station to prevent stoppages.

Cycle inventory–

It is the inventory ordered in lots to minimize storage and carrying costs. In another way, it is inventory to neutralize the carrying and storing cost for optimizing inventory ordering cost.

Be it any inventory type, an efficient inventory management system like BatchMaster ERP enables you to manage different items with easy tagging, classification, and item analysis.

Each method is intended to easily track material, reduce waste, and fasten the picking process. BME allows you to track inventory based on:

- Bin location ID

- Serial or lot number

- LIFO, FIFO, FEFO

- ABC analysis

With the help of BME, you can classify items, manage multiple units of measure, get the item details, set up variation methods, identify standard suppliers, set allocation methods, and various costs, and substitute for an item.

Due to the flexibility and versatility it offers in classifying inventory, BatchMaster ERP is the most loved ERP software, which also manages inventory meticulously, among the manufacturers globally.

BME offers the amazing capability of effective warehouse transfer. It facilitates inventory inspection and adjustment tasks with handheld devices. Besides these, BME supports inventory count. Cycle counts and physical counts are executed meticulously.

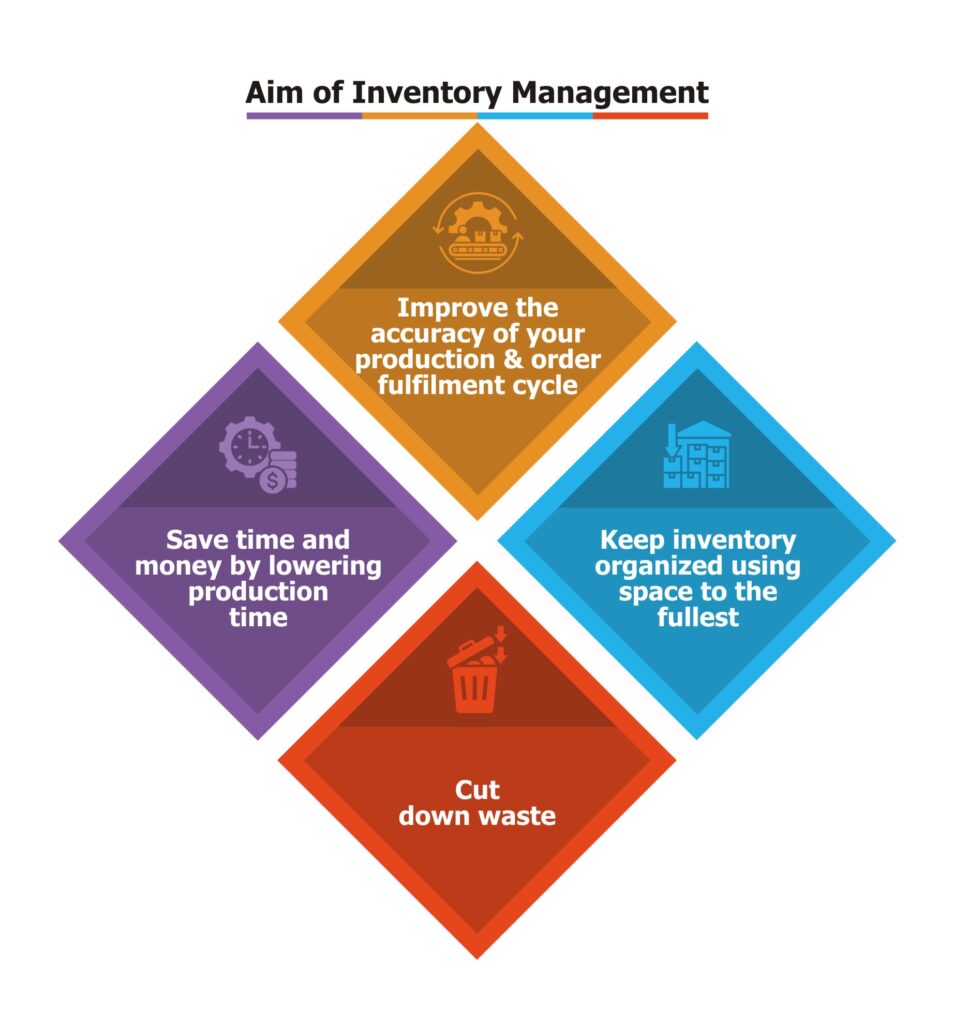

Aim of Inventory Management

4 Aims of Inventory Management-

- Improve the accuracy of your production and order fulfilment cycle

- Keep inventory organized, using space to the fullest

- Cut down waste

- Save time and money by lowering production time

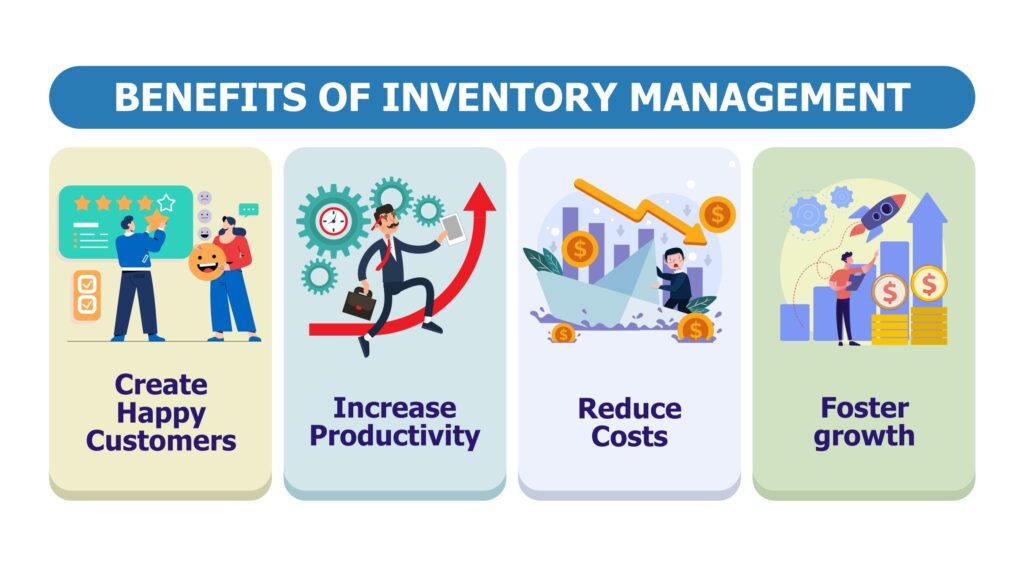

Why Inventory Management is Important?

Inventory management decides the viability of your business. It can be an asset or liability, depending on how you manage it. The better you are at managing your inventory, the better you will be at delivering and responding to customer orders.

The following are the main benefits of inventory management:

Create happy customers-

Customers today are very choosy and impatient. With growing options, they have at their disposal, they need their demands to be fulfilled almost instantaneously.

At such a juncture, the business that has a well-managed inventory and can deliver the right product in minimal time is the game-winner. It can foster happy customers which eventually leads to repeat business and fodder for future leads.

With an ERP like BatchMaster ERP, processes like inventory identification, staging, picking/packing/shipping all become faster. Such fast processes within the organization eventually accelerate deliveries and bring smiles to the faces of consumers.

Increase productivity-

Effective control of inventory will reduce the time and cost involved in manual inventory tracking, which most of the time is erroneous. By managing inventory effectively, businesses can invest time in useful and productive work.

Reduce costs–

By properly managing inventory, businesses can understand which products are fast sold, which have low response, and which are doing well.

By understanding this, they can plan procurement and reduce overstocking which requires immediate investment.

Besides the money required for stocking, overbuying also demands storage costs. With well-managed inventory, all these costs can be reduced, and the liquid money can be used for other requirements.

Various inventory reports of BatchMaster ERP help to identify the fast-sold goods, generate inventory costs for analysis, and plan for procurement with concise requirements.

This planning helps to avoid overstocking, or understocking. Besides, the software helps to stock seasonal items, trigger economic order quantity, and control co-products and by-products during production.

Foster growth –

Well-managed inventory fosters growth. With such inventory, businesses can respond to the demands at a wink, add new product lines, and grow.

Inventory management techniques-

Since inventory is a crucial part of a business, there are many techniques for managing it. These techniques are useful in maintaining the profit of a business.

Just in time (JIT) –

This inventory management technique aims to fulfil the demands exactly when it is generated, also known as zero inventory. It reduces waste, and overstocking, and maximizes efficiency by maximizing inventory turnover.

Economic order quantity (EOQ) –

Economic order quantity is an effective inventory management technique that allows manufacturers to determine the optimal quantity of materials required to meet customer demands, cutting excess inventory storing costs.

Safety stock inventory-

It stores just an ample amount of inventory before stock dries out. It protects stock outs and serves as a cover supply against unexpected demands.

BME supports these techniques by:

- Setting Reorder Point (ROP) – This is the level of inventory, below which an alert is generated for re-purchasing the item.

- Reserving inventory lots- The software always gives an alert before using safety stock.

- Defining EOQ.

Challenges in Inventory Management-

There are 4 major types of challenges that complicate the inventory management game for process manufacturers-

Overstocking and Understocking-

Balancing stock levels is one of the biggest hurdles manufacturers encounter. As, overstocking leads to higher storage costs and potential wastage for products with a limited shelf life.

On the contrary, understocking results in delayed production and ultimately missed sales opportunities. Achieving the perfect balance and ensuring optimal inventory all the time requires accurate planning and real-time visibility into inventory levels.

Demand Forecasting Issues-

Predicting customer demand is crucial but it becomes erroneous when performed manually. Poor demand forecasting disrupts production schedules and supply chain operations, making it essential for manufacturers to rely on advanced analytics and historical data.

Inventory Shrinkage-

Even a small amount of inventory shrinkage for a continuous period of time can lead to substantial financial losses for an organization. This requires manufacturers to implement stricter inventory controls involving periodic audits and advanced tracking systems to minimize inventory losses.

Managing Perishable Goods–

Process manufacturers often deal with the challenge of managing and using inventory before products expire. Companies failing to manage the proper rotation of materials experience a substantial financial loss. Undertaking efficient inventory management methods like FIFO and LIFO, track expiration dates and manage inventory accordingly, reducing wastage.

How Manufacturing ERP Simplifies Inventory Management-

Since every business is unique, techniques and tips for all can be different. Here are some tips that can serve as ready reference for you:

Identifying and tracking inventory

BatchMaster ERP lets define unique ID numbers that can be assigned to each product variation. This helps segregate various products and collect them fast when an order is generated.

You can assign bin numbers, UID, and attributes, and then assign these inventory items to specific bin locations. Besides, BME helps associate an item with:

- Warehouse or location

- Costing Methods- Last, Average, Standard, Market, etc.

- Tracking Method- Serial, Lot Method

- Lot Issue method- LIFO, FIFO, FEFO

- Classifications such as ABC analysis

- Lot attributes/characteristics

- Tracking from Pallet, Bin, and lot, to serial level

Use SKUs

BatchMaster allows defining various units of measure in terms of Weight, Volume, and Discrete. It allows storing in one unit, buying in another, and selling in a third unit.

It even allows one-click conversion of one unit to another at all levels- inventory, production, or shipping, thereby saving manufacturers from a lot of manual calculations and associated errors.

Forecast changes

Keep a tap of new trends, and customer preferences and make necessary changes as per the current and expected demands to assimilate changes.

Effortlessly perform Cycle and Physical Count:

BatchMaster ERP offers a dedicated module for physical and cycle count that can adapt to your physical count method and streamline every step of it.

Starting with the segregation of inventory to be counted, generation of tags, tallying of perpetual and physical inventory, banning any transactions from executing during the count-in-process, and a lot more.

Integration with Handheld devices:

BME supports all kinds of hand-held devices used for scanning inventory. It saves users from hundreds or thousands of keystrokes.

The inbound and outbound transactions happening in the warehouse can be recorded right where and when they are happening, always giving a real-time view of inventory to all the associated departments.

Rely on cloud-

Make use of cloud technology to manage your business from anywhere, anytime. Cloud-based inventory management systems can come to rescue inventory management-related issues.

BME offers a cloud-based ERP solution. This solution comes as SaaS, on a subscription model, hence it is cost-effective and gives mobility. The cloud-based ERP is highly secure, and safe and comes with 24*7 customer support and regular backups.

Conclusion –

The success of a business largely depends upon the effectiveness of its Inventory management. BatchMaster ERP, along with providing an inventory management solution, provides numerous benefits that a manufacturer can leverage to manage not only inventory but all mission-critical business activities.

BatchMaster ERP is a process manufacturing ERP. It has been providing industry-specific solutions, including inventory management solutions to many process manufacturers for the last 30 years. Along with the above-mentioned functionalities and uses, there are many more that BatchMaster ERP offers. To know them all, please connect.

Inventory FAQs:

What is Inventory Count?

Inventory count is the process of physically counting and checking the conditions of goods parked in warehouses. It helps tally physical and perpetual inventory or inventory on records. This process gives a fair idea of available inventory/stocks in the warehouse and its condition.

For accounting purposes, inventory count helps assess debts and assets. Inventory count helps inventory managers to identify which stock is moving fast and based on this information they forecast stock needs and manage budgets.

What is the Average Inventory Cost?

Divide goods available for sale by the number of inventory units on hand, and the result is the average inventory cost. Average inventory cost can be useful to compare the cost of goods available for sale at different locations or different time periods.

What are the Key Considerations for Effective Inventory Management Software?

An effective inventory management software must have reporting, forecasting, analysis, and accounting capabilities along with inventory alerts and automatic reordering.