Production is the heart and soul of any manufacturing enterprise. It is the process of converting raw materials into finished products, and it plays a vital role in the financial well-being and overall success of a company.

Efficient production management is essential for ensuring smoother operations, meeting customer demand, and delivering high-quality products. It can also help to reduce costs, improve profitability, and boost customer satisfaction.

Do you want to elevate your business to new heights through efficient production management? Dive into this comprehensive guide to explore the world of production and how it can be expertly managed to drive success.

TABLE OF CONTENT-

- Overview

- What is Production Management?

- Aim of Production Management

- Stages of Production Management

- What is Production ERP Software?

- How Production is Managed using ERP Software?

- How BatchMaster ERP’s Production Module help in Managing Production?

Overview:

Think about running a factory like working in kitchen. You want everything to work together smoothly. Factories are also like magic kitchens, and they have problems that need fixing.

In today’s fast-paced business landscape, production managers who rely on old, manual methods and mountains of paperwork, find themselves struggling to maintain effective production management. These outdated practices often lead to missed production schedules, inaccurate forecasting, and a plethora of errors. The combined effect ultimately results in unnecessary costs and missed opportunities.

In light of these challenges, production managers are turning to innovative solutions, such as Production ERP Software. Such a solution helps them to navigate through the complexities of modern production processes.

This article dives into the world of production management, revealing how technology can help managers overcome their daily challenges. Let’s dig in to discover how these systems can transform your production process!

What is Production Management?

Production management is about making things run smoothly when creating products. It involves planning, organizing, and overseeing the entire process, from getting the raw materials to processing them a finally delivering the finished product. A great production management system helps everything work efficiently, saving time and money.

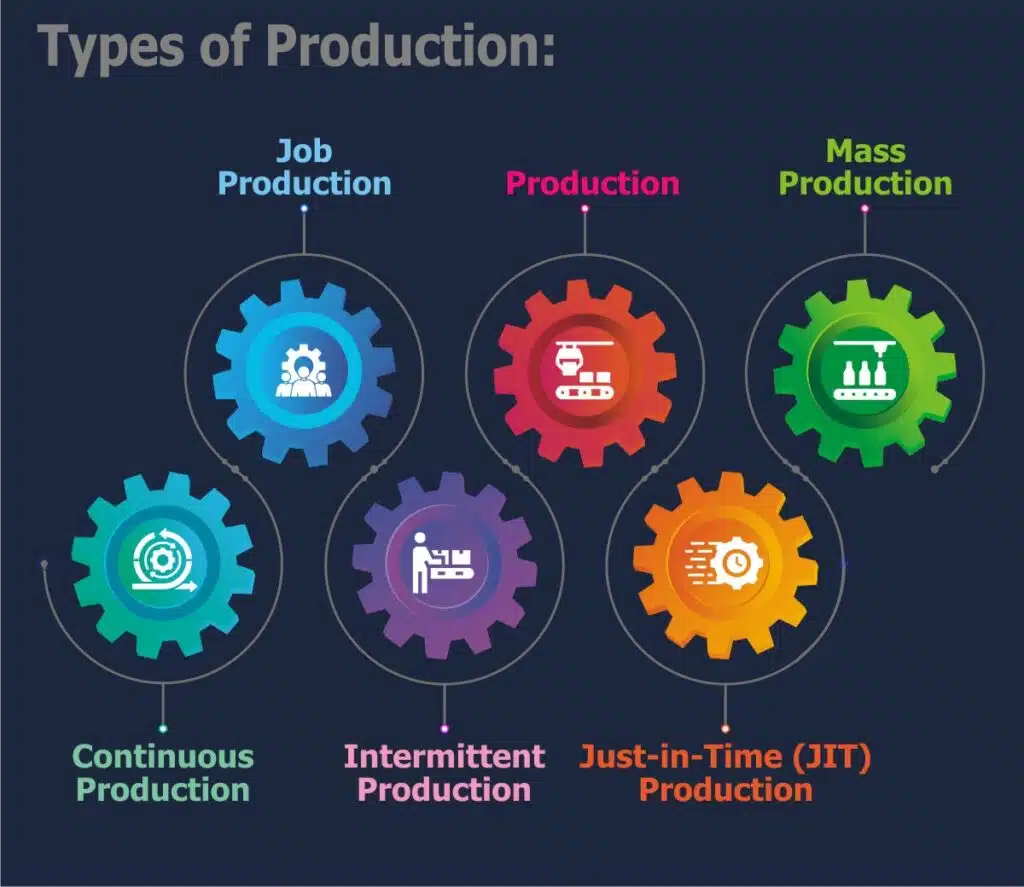

Types of Production:

There are several types of production methods used in various industries, each with its characteristics and applications. Here are some of the common types of production:

Job Production:

- In job production, products are custom-made to meet the specific requirements of individual customers.

- It is often used for unique or highly customized products, such as bespoke furniture or custom-made machinery.

- Labor and materials are usually more expensive in this type of production due to the personalized nature of the work.

Batch Production:

- Batch production involves producing a set or batch of products at a time, followed by a changeover to a new batch.

- This method is flexible and cost-effective for producing moderate quantities of items with some degree of customization.

- Examples include bakeries making batches of bread or pharmaceutical companies producing a limited run of medication.

Mass Production:

- Mass production is characterized by the continuous, high-volume production of standardized products on assembly lines.

- It is highly automated, resulting in lower production costs per unit.

- Products made this way include consumer electronics, automobiles, and household appliances.

Continuous Production:

- Continuous production, also known as continuous processing, involves non-stop production of large quantities of identical products.

- It is commonly used in industries where raw materials are continuously processed into finished products, such as petroleum refining or chemical production.

- The process is highly automated and often operates around the clock.

Intermittent Production:

- Intermittent production combines elements of both batch and mass production. It is used for products with varying demands.

- Production runs are based on specific orders, and setups may change for different products.

- This method allows for some customization while still benefiting from economies of scale.

Just-in-Time (JIT) Production:

- JIT production is a subcategory of lean production, emphasizing the delivery of components or materials to the production line just when they are needed.

- This minimizes storage costs and excess inventory, resulting in cost savings and reduced waste.

- JIT is commonly used in manufacturing environments where efficiency and cost reduction are essential.

Be it any production type, an efficient production management system enables you to manage different items like inventory, workforce, production schedules, quality control, and cost optimization with precision and ease.

Aim of Production Management

Production management aims to effectively manage, control, and plan all aspects of production activities in a way that production yields cost-effective quality output, always. It involves coordination among various factors like labor, machines, materials, technology, etc.

The production management heads towards achieving the following objectives:

- Optimum resource utilization – Production management helps to utilize various resources like labor, raw materials, money, time, and technology to the maximum level possible.

- Timely delivery – With the help of production management, organizations aim to deliver products on time and meet commitments. This involves setting up timeframes for production and making production schedules.

- Quality control – Production management helps control the quality of the products. Maintaining high-quality products is essential for market viability. Quality control measures are crucial to avoid defects and rework.

- Cost reduction – Production management aims at controlling and reducing the cost of production. While doing so, it makes sure that there is no compromise with quality.

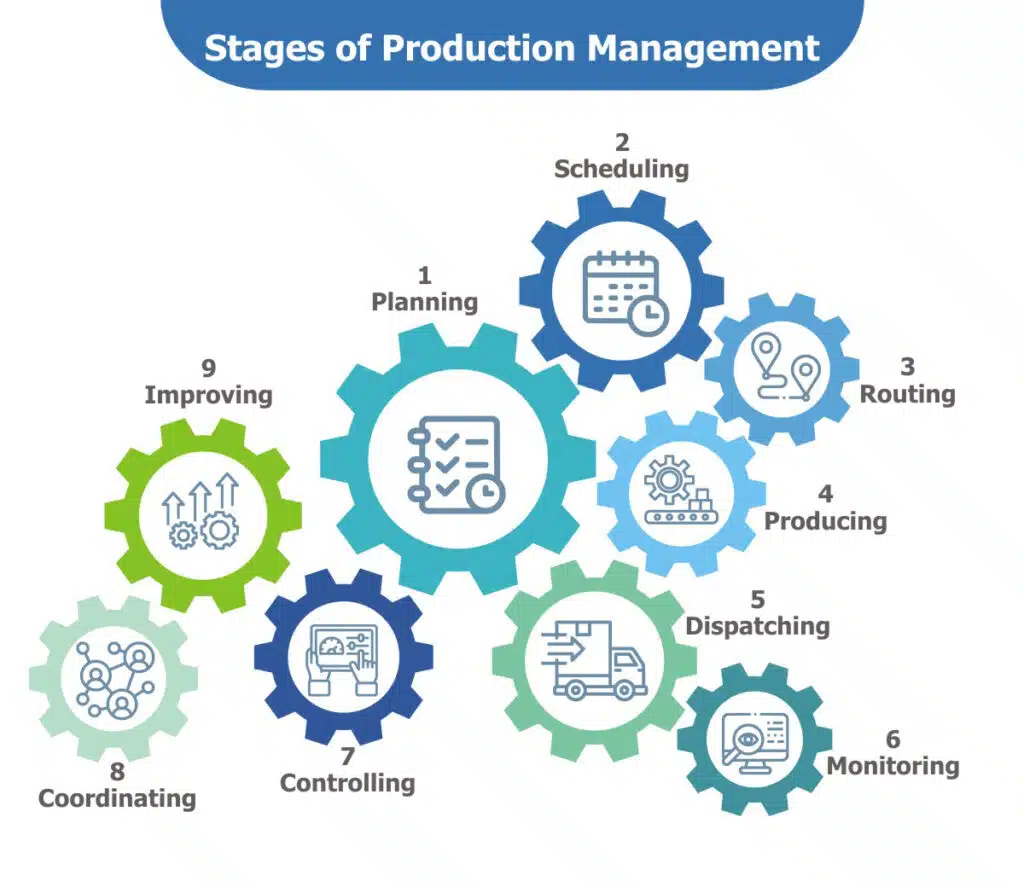

Stages of Production Management

The stages of production management are:

- Planning: This stage involves defining production objectives, determining the required resources, and creating a production plan.

- Scheduling: Once the plan is in place, scheduling allocates resources, time, and tasks to meet the production goals efficiently.

- Routing: Routing is about defining the best sequence of operations and the path through which products or services will flow.

- Producing: This step is about actually performing the operations/process that will take up the components required to produce the end products.

- Dispatching: This stage involves issuing instructions to the shop floor or workstations, ensuring that the production process is initiated as per the schedule.

- Monitoring: Continual monitoring of the production process is crucial to track progress, identify deviations, and make necessary adjustments.

- Controlling: Controlling ensures that the production process stays on track by making real-time decisions and taking corrective actions when needed.

- Coordinating: Coordination ensures that all elements of production work together efficiently and harmoniously.

- Improving: Continuous improvement is an ongoing stage that involves optimizing production processes, reducing waste, and enhancing efficiency.

These stages help in achieving efficient and effective production management.

What is Production ERP Software?

Imagine this scenario: You’re a production manager in a food processing plant. You’ve just received a significant order for a new innovative line of your product. This product is to be delivered to a major retail chain on time for a seasonal promotion.

You’ve initiated production, but due to poor production management you encounter issues like inaccurate inventory estimates, production bottlenecks, machine breakdown, etc., which result in a delay in the delivery.

Consequences:

- Lost Sales: The retail chain loses trust in your ability to deliver on-time, and they cancel the order.

- Unsatisfied Customers: End customers miss out on the seasonal product, leaving them disappointed.

- Brand Reputation Damage: Your Company’s reputation suffers as it fails to meet a high-profile commitment. Moreover, the competition an easily encash this situation.

Sounds like a nightmare, right?

Efficient production management and control are critical for manufacturing organizations to meet market demands and achieve their goals. This underscores the vital role of production management in the success of a profitable company.

Production ERP software can be the key for avoiding such pitfalls. It ensures accurate planning, inventory management, and production execution to meet customer expectations. Such promptness secures your company’s reputation.

How is Production Managed using an ERP Software?

The production planning module in production ERP software is a powerful tool that enables manufacturers to work more efficiently by effectively managing internal resources. This effective management help organizations to meet customer orders and demands efficiently.

It takes charge of production activities and assesses production capacity, raw material requirements, bill of materials, or substitute bill of materials to fulfill demand accurately.

It finds the most efficient way to produce finished goods while considering various lead times to meet production demand.

The outcome is a feasible manufacturing plan that guides the business in achieving its production goals. This seamless coordination and organization of resources and activities contribute to the overall efficiency and success of manufacturing operations. The production process is then executed according to the plan.

The Production Module in an ERP comprehensively facilitates all manufacturing activities, from Batch Creation to ticketing, batch issuing, tracking Work in Progress (WIP), inspecting production, closing batches, and ultimately conducting quality checks on the output.

How BatchMaster ERP’s Production Module help in Managing Production?

BatchMaster ERP is a powerful cloud-based production ERP software that excels in elevating production planning, batch processing and control for manufacturers. By leveraging the capabilities of this production ERP software, manufacturers gain the ability to streamline their production processes, conduct rigorous quality checks across raw materials, processes, and finished products, and access a pool of suppliers. Additionally, the production module within the ERP system facilitates seamless batch production.

The system includes both the Material Resource Planning (MRP) and Material Production Scheduling (MPS) modules, enabling manufacturers to efficiently plan production and manage the necessary materials.

MPS facilitates production cycle planning based on forecasts, demand, and stock availability, ensuring materials and components are ready for production and that manufacturing occurs on schedule.

It calculates required quantities, considers existing orders and stock across warehouses, and recommends ordering the remaining needed quantity. This integrated approach streamlines manufacturing operations and minimizes disruptions.

The Production module in BatchMaster typically focuses on streamlining and managing the production processes within a manufacturing facility.

Following are some specifics related to how this module aids manufacturers:

Creating Batches:

ERP systems like BatchMaster facilitate the creation of batches by providing a centralized platform to define and organize production runs.

Basically, once the MPS suggests a plan, batches can be directly created on a click against it. Alternatively, the module even allows creating batches from the Sales Order. Manual creation of batches is always possible, nonetheless.

These batches hold specifications, such as formula/recipe to be used, no. of runs, labor required, quantity to be produced, quality checks and inspection plans to be applied, and such.

SuperBatch™ and Runs Functionalities:

BatchMaster’s SuperBatch™ concept is instrumental in managing multi-level batches efficiently.

It streamlines the production of multiple intermediate and finished goods batches simultaneously.

Runs functionality in BatchMaster enables batch production to be achieved in individual, workable batches during a continuous period of operation, ensuring optimal efficiency and coordination.

Critical Material:

Once the batches are created, BatchMaster ERP allows running a Critical Material Report for them. The report suggests materials that are insufficient to carry out production. A Requisition can be created, right here, for such materials and can be sent for approval and procurement to the Production Manager. This ensure continuous production by ensuring al material is available before the production starts.

Batch Sizing:

BatchMaster ERP allows flexible batch sizing, enabling manufacturers to adjust production quantities based on demand, resources, or other variables. The batches can be sized based on one or more materials, availability of one or more materials, based on adjusting weights or volumes of one or more material, etc. User just need to enter the new quantity, the system does the rest, saving them from all the laborious calculations and associated errors.

Substitution of Batch Materials:

Unavailability of some material or introduction of newer materials is common in process manufacturing. Production management software manages batch substitution dynamically, allowing substitution on various parameters like unavailability of one or materials, direct substitution, etc., again without all the complex number crunching.

Batch Ticket:

A batch ticket is a document or record used in manufacturing and production processes to detail the steps, materials, and instructions necessary for the creation of a specific batch or lot of a product. It serves as a comprehensive guide for operators, ensuring that each batch is produced consistently and in accordance with established standards.

BatchMaster’s Production Module allows generating Batch Tickets and performing a number of operations like lot allocations, issues, applying quality checks, performing batch sizing and substitution, calculating batch cost along with labor, overheads and such.

Part Closure & Batch Closure for Dispatch:

BatchMaster facilitates part closure, ensuring that each stage of production is completed and documented before moving on to the next. This feature is useful for urgent deliveries, or deliveries in parts.

Batch closure is streamlined, ensuring that all necessary processes, including quality checks, issue, and compliance requirements, are met before the batch is marked as completed. The batch close updates the inventory quantities- increasing the quantities of finished goods, decreasing that of raw materials and packaging involved. It even allows comparing the expected yield to the actual yield giving manufacturers an insight into the losses.

Efficiency and Information Consolidation:

BatchMaster ERP bridges the gap between software and actual operations, increasing overall efficiency in production processes.

The system consolidates batch information, ensuring that all relevant data, including intermediate and finished goods production batches, is available under one single record. This reduces the need to manage separate data records for different production stages.

Quality and Compliance:

BatchMaster allows manufacturing as per cGMP. It generates Manufacturing Batch Records, Batch Manufacturing Records, COA, SARA Reports, FDA Labels and more, essential to stay compliant. On the quality front, it allows performing quality checks and inspections along and after the process to ensure expected quality and reduce rework.

On Concluding,

Today’s manufacturing landscape requires innovative solutions like Production management software to streamline production, especially in industries like Food & Beverages, Pharmaceuticals, Personal Care & Cosmetics, Paints & Coatings, Specialty Chemicals, and such.

And, BatchMaster ERP’s extensive features, including SuperBatchTM and Runs, allow manufacturers to adjust to changing needs, keep accuracy, and streamline operations from batch creation to dispatch. These features make it easier to manage complex production processes efficiently. The system’s ability to consolidate information enhances visibility and control over the entire production lifecycle.

So, don’t miss the chance to enhance your production processes. Discover how software like BatchMaster ERP can boost efficiency, quality, and continuous improvement. Elevate your production management now – Contact us to learn more about our solutions!