Pharmaceutical manufacturing is a highly sensitive industry that deals with products (drugs, vaccines, medical devices, etc.) that have direct impact on human life.

And since there is no option of a second chance for the patient consuming any pharma product, the quality, efficacy, and purity of the products are much needed virtues.

This calls for an effective inventory management, which in itself is a difficult job.

It is predominantly a difficult task, as any pharmaceutical company handles hundreds of different types of products at a single time.

This includes huge amount of raw materials movement, as well as packaging of the finished products.

Given the enormity and complexity of things, the pharmaceutical manufacturers are quite rightly faced with a number of challenges when it comes to inventory management.

But before knowing those challenges, it is important to understand the importance of inventory management in pharmaceutical manufacturing.

Inventory management in pharmaceutical manufacturing

The simple objective of inventory management in pharmaceutical manufacturing, as in any other manufacturing industry, is to achieve required levels of production, and to maintain a supply of inventory, which is absolutely essential to maintain the flow of operations, meet the fluctuation in product demand, and to allow flexibility in production scheduling.

The scope and application of inventory management in pharma manufacturing also covers demand forecasting, warehouse management, process auditing, etc.

The pharmaceutical manufacturers need to ensure that at any given time, the production is running to the full capacity of the plant.

And for that, the inventory stock must always be adequate enough in the warehouse so that the operations do not come to a halt due to lack of raw materials.

At the same time, the manufacturers also need to ensure that they do not reach the situation of over stocking, which affects their working capital, and increases the risk of obsolete inventory. But achieving these objectives is challenging.

Coming back to the challenges manufacturers face with effective management of inventory, there are quite a few actually. These include the need to:

- Ensure the availability of products which are frequently essential to health or life itself.

- Keep a record of receipts, custody, and issue of materials.

- Manage the perishable raw materials, intermediates and finished goods.

- Reduce the inventory/material wastage.

- Minimize the investment in inventory.

- Ensure inter-department coordination for meeting the requirements for materials.

- At times rely on a very small number of supply options.

To meet these challenges, the pharmaceutical manufacturers need to know how fast a product or its ingredients need to be used before they expire.

For that they need a tool, which can additionally help keep a record of inward/outward inventory, reduce wastage, meet regulations, and ensure that the materials are available in adequate numbers for production.

A pharma ERP software assures all of that, giving the manufacturers complete control over their inventory.

[wp-video-popup

video=”www.youtu.be/Z1D8h3tuR8o”]

Here’s how a pharmaceutical manufacturing software can help

Any good pharma inventory software allows pharma manufacturing companies to have a superior hold over their inventory, and to control material wastage and monitor inventory levels through its dedicated inventory management module.

With its help, the manufacturers can easily arrange the material required for production, set inventory targets, monitor the usage, create alerts for replenishment, reconcile the balances, and also generate inventory status reports in no time.

Integrates with the supply chain:

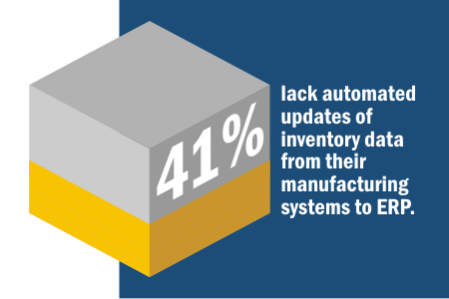

A recent survey of over 100 pharma manufacturers conducted by AMR had some startling revelations. 41 percent of the total respondents said they didn’t have automated updates of inventory data from their manufacturing systems to ERP.

This was huge, considering a significant number of pharma manufacturers had no connect between their plant floor and top floor, and virtually no hold over the supply chain.

A good pharmaceutical manufacturing software keeps a record of all the inward/outward inventory, i.e. of receipts, custody, issue of materials, and the goods that go out of the premises, and allows the manufacturers to seamlessly integrate and align with the business’ supply chain.

Syncs departments both internal as well as external

This effectively means that there’s not just a synchronized co-ordination between the internal stakeholders, viz., the management, maintenance, production, marketing and finance departments and other departments of the company for meeting their requirements for materials and spares, but also between the internal & the external stakeholders.

For instance, the purchase managers can integrate their data with their suppliers’, ensuring that lead times are at their minimum and the communication between the various stakeholders is transparent.

This means that the customers can track shipments, and the management can get real-time updates on the stock levels, knowing when to order and exactly how much to order, and also on the items in transit.

This substantially decreases the chances of inventory over-stocking, as well as wastage.

ERP brings in traceability too

A good pharma inventory software offers lot traceability, and along with it, certain specific capabilities such as product recalls, farm-to-fork traceability, etc., which help the manufacturers manage complete tracking and tracing of all ingredients used in production.

The manufacturers can track all the ingredients back through the supply chain, and can thus minimize recall size, ensure sustained consumer faith in their products, and attain quick response time, etc.

Pharma manufacturing software’s scope covers demand forecasting as well:

Equipped with its forecasting tools, an ERP can help ensure optimal inventory control.

Through the use of historical sales data, trends and patterns of sales, information on lead times, inventory receipts etc., it can offer key data which can be used to assess demand levels so that the future performance can be predicted.

This ensures that the customer demands are invariably anticipated and met, losses are minimized, and revenue is maximized.

Shelf-life & expiration dates:

Most importantly, pharmaceutical manufacturing software can help the manufacturers achieve the ability to determine the shelf-life and expiration dates of the inventory.

This way, they can manage the perishable raw materials, intermediates and finished goods.

A pharmaceutical manufacturing software notifies the manufacturers through alerts when the ingredients approach their expiration dates, and even when the inventory in stock is about to go below the optimal levels.

As a result, they can manage their inventory efficiently, and in turn reduce wastage, mitigate obsolescence risk, and ensure quality in the overall production process.

Other things pharma manufacturing software can do:

It is a known fact that the pharma manufacturers got to procure raw materials from recognized suppliers who have the ‘Supplier Verification’ and provide safe materials.

A pharma ERP only accepts materials purchased from the authorized as well as recognized vendors whose details are stored in the system.

If there’s any discrepancy, alerts are automatically raised, thus ensuring only quality material is received from the verified supplier.

A pharma inventory software also allows the manufacturers to have a number of verified suppliers at their disposal at any given time, as it can store their details in the database, and allow the manufacturers to have multiple options to choose from when it comes to procurement.

Conclusion

Pharma inventory software are designed to automate and streamline the inventory management processes, and reduce the stress of pharma manufacturers, eventually propelling them towards business growth.

BatchMaster ERP for pharmaceuticals is one such solution, which helps the pharma manufacturers manage their inventory efficiently and effectively.

Get in touch with our pharma experts for a free demo if you are looking for a pharma manufacturing software.