Manufacturing is the backbone of the global economy, fueling innovation and delivering products to millions of consumers. However, not all manufacturing is the same—two dominant paradigms exist: Discrete and Process Manufacturing.

Understanding their unique methods, industries, and processes is essential for selecting the right ERP software, complying with regulations, and achieving operational excellence.

Understanding Manufacturing Types

What is Discrete Manufacturing?

Discrete manufacturing creates finished products by assembling components. Each item is countable and individually identifiable, think cars, smartphones, and industrial machinery.

Production is driven by a Bill of Materials (BOM), outlining every component required for assembly. Manufacturers can customize each product, producing them in units or batches.

Key Characteristics:

- Products assembled from multiple parts

- Allows for customization and personalization (e.g., model, features)

- Finished products can be disassembled and serviced

- Production follows “make-to-stock”, “make-to-order”, or “assemble-to-order” workflows

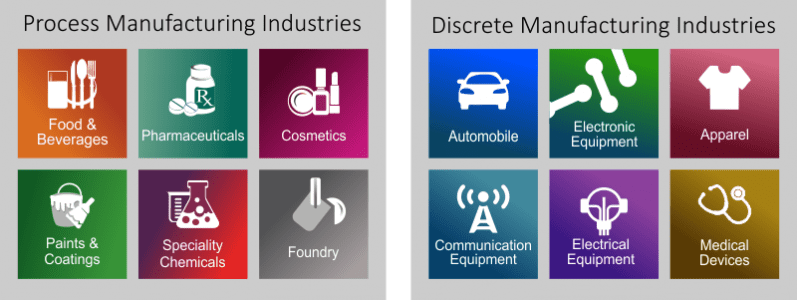

Example Industries:

- Automotive

- Aerospace & Defense

- Electronics

- Industrial Equipment

- Apparel & Fashion

What is Process Manufacturing?

Process manufacturing produces bulk items by blending or processing raw materials according to specific formulas or recipes. The final product cannot be disassembled into its original ingredients—think food items, chemicals, and beverages.

Key Characteristics:

- Involves chemical, physical, or thermal changes (mixing, boiling, fermenting, etc.)

- Products measured by mass, volume, weight (kg, liters, tons)

- Formula-driven production (consistent quality and traceability)

- Typically continuous or batch-oriented

Example Industries:

- Food & Beverage

- Pharmaceuticals

- Paints & Coatings

- Chemicals & Petrochemicals

- Cosmetics & Personal Care

Comparison Table: Discrete vs. Process Manufacturing

| Discrete Manufacturing | Process Manufacturing |

| Products are comprised of components that can be touched, and counted. | Products are manufactured using formulas or recipes |

| Parts can be broken down & disposed off or recycled after production | Products cannot be broken down back into raw materials |

| Uses Bills-of-Material | Uses formulas or recipes |

| Assembles in a linear or routing way | Blends in a batch |

| Involves joining, attaching, fixing, assembling etc. | Involves grinding, boiling, mixing, churning, etc. |

| Doesn’t involves change of volume or density | Volume, density, mass, physical properties all get changed here |

Key Differences and Challenges

1. Traceability & Inventory Management

- Discrete manufacturing tracks every unit with serial numbers and individual part handling, perfect for warranty and after-sales service.

- Process manufacturing, however, tracks lots and batches, prioritizing ingredient tracing (essential for recalls or compliance audits).

2. Production Planning and Scheduling

- Discrete: Scheduling revolves around assembly line efficiency, order prioritization, and custom configurations.

- Process: Scheduling must account for batch sizes, formula changes, clean-in-place (CIP) routines, and raw material variations.

3. Quality Control

- Discrete: Focused on dimensional accuracy, tolerances, and defect inspection.

- Process: Prioritizes consistency, purity, and adherence to recipe specifications.

4. Compliance & Regulations

Process industries face stringent requirements (FDA, FSMA, EPA for chemical/food/pharma), while discrete manufacturing often complies with ISO, safety, and warranty standards.

Why ERP Fit Matters

Generic ERP systems can handle accounting and basic operations, but manufacturers benefit greatly from software tailored to their production style.

- Discrete ERP: Manages BOMs, serial numbers, assembly workflows, and aftermarket support.

- Process ERP: Manages batch production, recipe management, lot tracking, and compliance documentation.

BatchMaster ERP specializes in process manufacturing, providing formula/recipe management, compliance, and traceability.

OptiPro ERP with SAP Business One is designed for the needs of discrete manufacturers—assembly, configuration, and service modules.

Case Studies: Real-World Transformation

Case Study: Leading Pharma Company (Process Manufacturing)

A pharma manufacturer adopted BatchMaster ERP for formula management and batch traceability.

- Achieved full compliance (FDA CFR 21 Part 11)

- Reduced lot recall times by 50%

- Streamlined quality control reporting

Case Study: Precision Equipment Manufacturer (Discrete Manufacturing)

A discrete manufacturer implemented OptiPro ERP, enabling modular BOMs and improved order tracking.

- Cut lead times by 25%

- Enhanced order customization

- Increased service revenues through better product traceability

Latest Trends Impacting Manufacturing

Digital Transformation

- IoT sensors for shop-floor monitoring (predictive maintenance, process optimization)

- AI-powered quality control and analytics

- Cloud ERPs: flexibility, remote access, and integration with MES/PLM systems

Sustainability

- Waste reduction through lean manufacturing (discrete)

- Energy-efficient reactors, recycled solvents (process)

Regulatory Evolution

- Strict food safety (FSMA, EU FIC) in process industries

- Increasing demand for end-to-end traceability in both sectors

Watch: Understanding Discrete vs. Process Manufacturing & Choosing the Right ERP

Frequently Asked Questions

Can a Single ERP Handle Both Manufacturing Types?

Some ERPs provide features for both discrete and process manufacturing. However, most companies find better results with specialized solutions—such as BatchMaster ERP for process industries and OptiPro ERP for discrete sectors—ensuring workflows and compliance needs are fully supported.

How Do I Know Which ERP Is Right for My Company?

Audit your core processes—if formulas, batch tracking, or compliance are crucial, choose process ERP. For assemblage, order customization, or aftermarket service, choose discrete ERP.

Can ERPs Improve Sustainability?

Absolutely—process ERPs help optimize resource use, reduce contamination, and cut waste. Discrete ERPs help with lean inventory, modular design, and energy management.

When Should You Switch ERP?

When your current system cannot manage recipes/batch vs. BOM/assembly, or struggles with compliance updates.