Food Manufacturing ERP Software

Quickly streamline and scale up your operations, while reducing costs and complying with industry regulatory mandates.

Integrate. Extend. Excel.

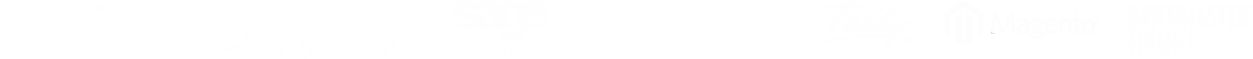

Food ERP Software Functionality

Whether you private-label, co-pack or produce your own line of food and beverage products, BatchMaster Software manufacturing and ERP applications offer your staff all the time-saving tools and real-time actionable data they need in these areas:

See How Our Leading Food Manufacturing ERP Systems Can Help You By

- Streamlining Business Operations

- Accelerating Product Development

- Controlling Inventory Levels

- Scaling Up Production

- Ensuring Quality Standards

- Complying With Industry Regulations

- Improving Real Time, Accurate Reporting

- Growing Your Business!

Food Processing Software That Will Change the Way You Work

Inventory management tracks, adjusts and moves ingredients, packaging, intermediates, co-products, by-products and finished goods, in terms of their QC statuses, weights, volumes, and units, as well as plant locations and licenses. Here are just a few supported transactions:

- Maintain allergens, safety, certifications, and other industry specific attributes and documents

- Allocate inventory based upon expiry dates, certifications and quality status

- Adjust batch jobs based upon the variable characteristics of inventory

- Execute warehousing tasks with mobile devices

Lot controlled inventory is managed from receiving into production thru shipping, thus maintaining the lineage of all raw materials, intermediates and finished products, including co-products and by-products. Here are just a few supported transactions:

- Auto assign lot numbers during receiving and production

- Mandated capture and validation of lot numbers throughout the product lifecycle

- Execute “bi-directional” searches in seconds using a graphical lot traceability tool

- Generate recall letters for suppliers and customers

Quality control and quality assurance capabilities are built all processes managed by our food manufacturing software, from receiving into production thru shipping. Here are just a few supported transactions:

- Setup QC tests with accepted values, tolerance values, sample and recount values

- Execute inspection plans, checklists and QC tests against products, people and equipment

- Generate COA and production deviation documents

- Manage adverse reporting, customer complaints, deviations, and nonconformance situations

Production manages the mix, blend, fill, assemble, and other manufacturing processes for intermediates and finished goods, including co-products and by-products, across facilities. Here are just a few supported transactions:

- Dynamically sizing, linking and scheduling dependent batch jobs together

- Managing equipment and resource availability and capacities

- Reworking intermediates and finished goods and capture deviations

- Automatically back flushing inventory for partially or fully

closed jobs

Formulation allows multiple users to manage multiple specification versions for products, including intermediates, co-products and by-products, separately from their packaging specifications (BOM). Here are just a few supported transactions:

- Dynamically adjust ingredient weights/volumes to meet property target values

- Account for fixed and variable labor costs, including consumable costs

- Analyze and compare specifications / versions

- Employ multi-level workflow approval process

Industry specific compliance are built into every process to ensure federal and industry specific regulatory mandates are met. Here are just a few supported transactions:

- Alert formulators when specs exceed industry established levels

- Mandate the capture of item, user and location data (CFR 11)

- Maintain key transactional history for auditor reports (e.g. Master Batch Records)

- Generate industry required product and safety labels and documents

MPS creates the optimal number of batch jobs required to meet current and forecasted demand, then MRP creates the optimal number of purchase orders to meet the scheduled production schedule. Here are just a few supported transactions:

- Establish short, medium and long-range planning periods

- Run by facility, or by an item or a range of items across facilities

- Consolidate supply and demand across facilities

- Perform “what-if analysis” while planning production

Run a Complete ERP Solution

Food Manufacturing, Financials, Supply Chain, and CRM all on a single world class business platform

Cloud Deployment Available

Large scale to small business manufacturers can take advantage of our “private cloud” solution with monthly subscription programs

Industry Sectors

Meet Some of Our Customers

About Us

BatchMaster Software is a leading provider of recipe-based, food manufacturing ERP solutions that help companies worldwide meet their corporate objectives.

more than

2,000

Happy Customers

more than

2,500

Implementations

more than

40,000

Users

more than

30

Years of Experience

more than

500

Employees

Worldwide

7

Offices